Bending die single oil cylinder middle cutting mechanism

A technology of cutting mechanism and single oil cylinder, which is applied in the field of machinery, can solve the problems of unrealized products and bulky volume, and achieve the effect of improving the flexibility and accuracy of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

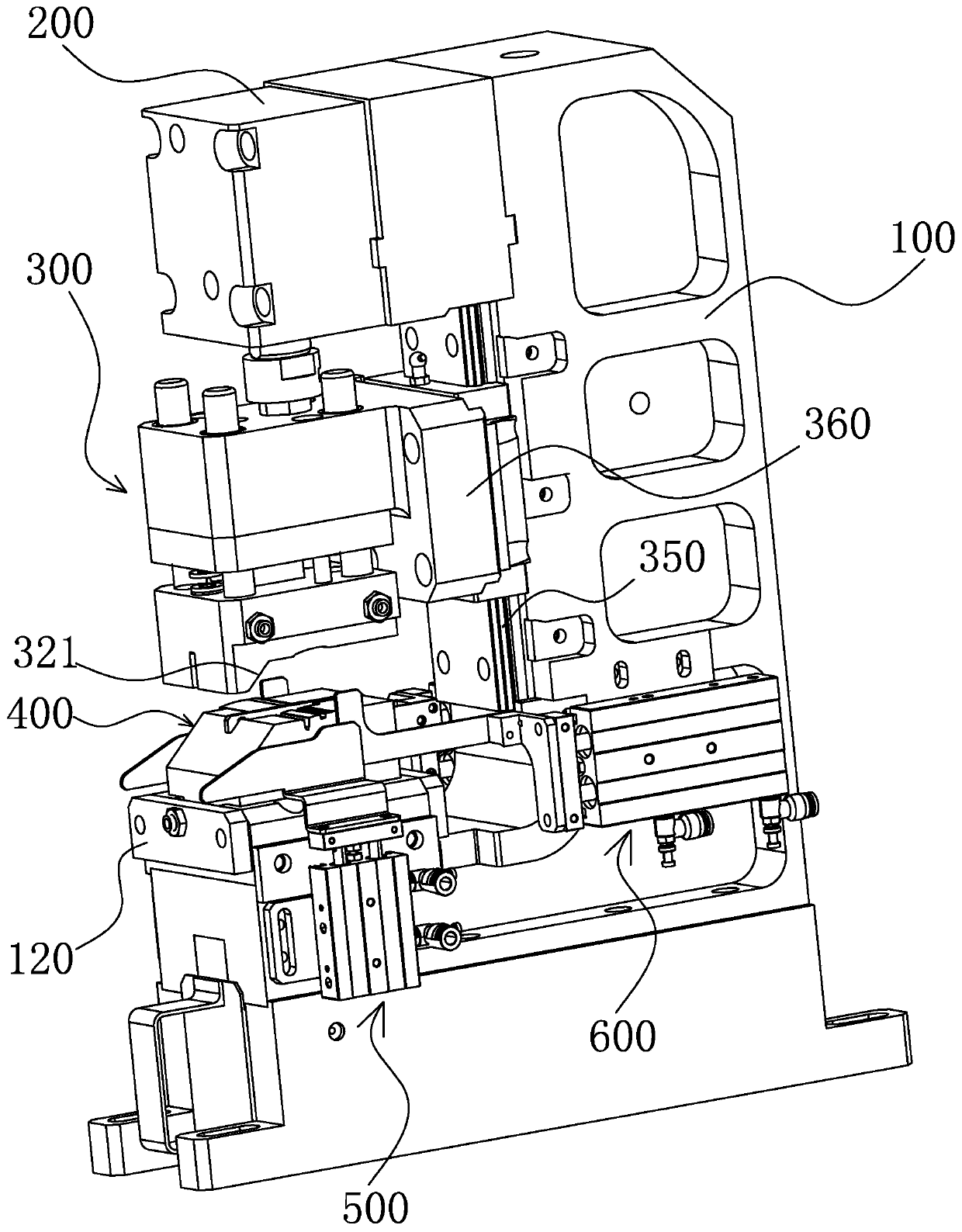

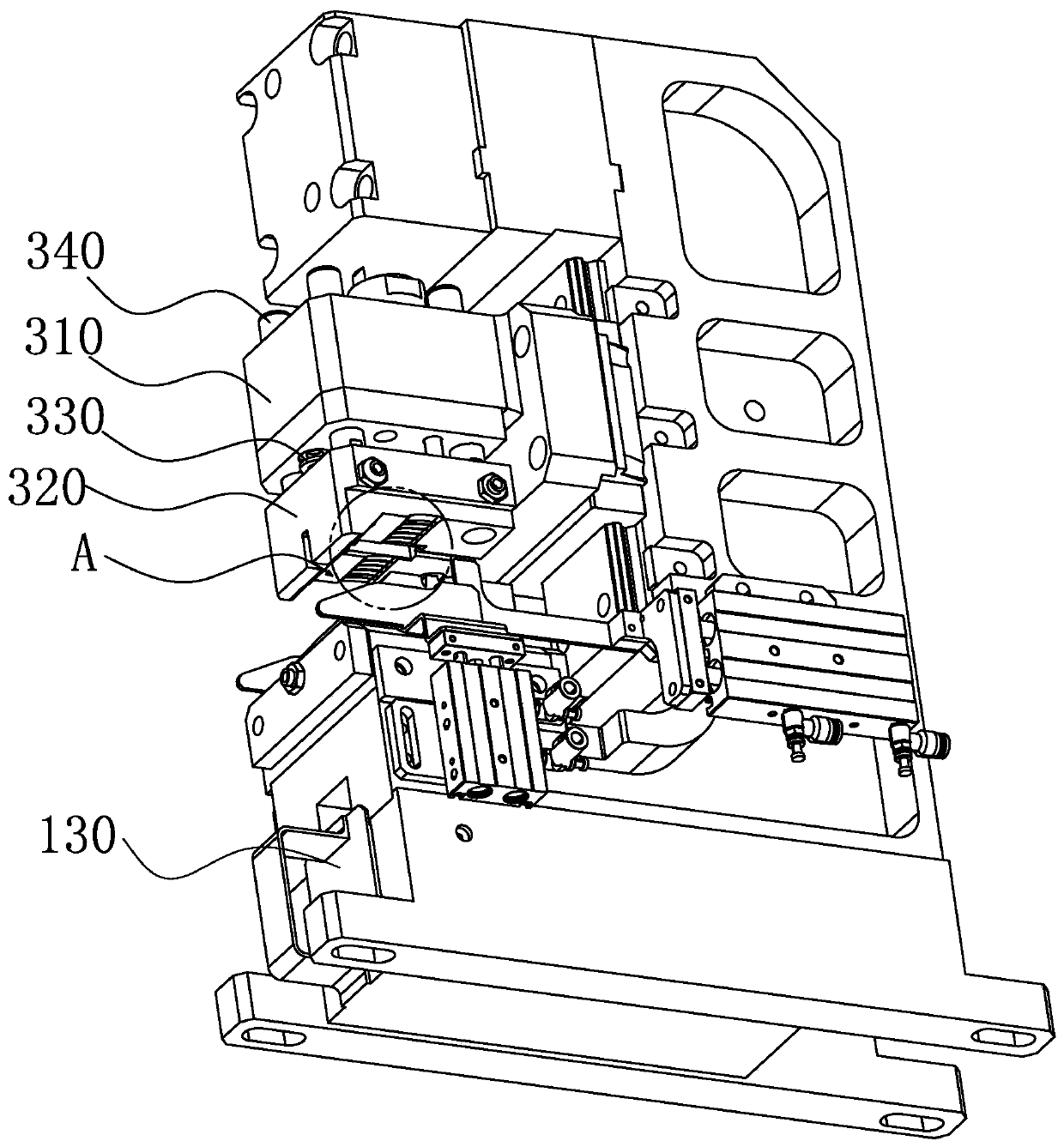

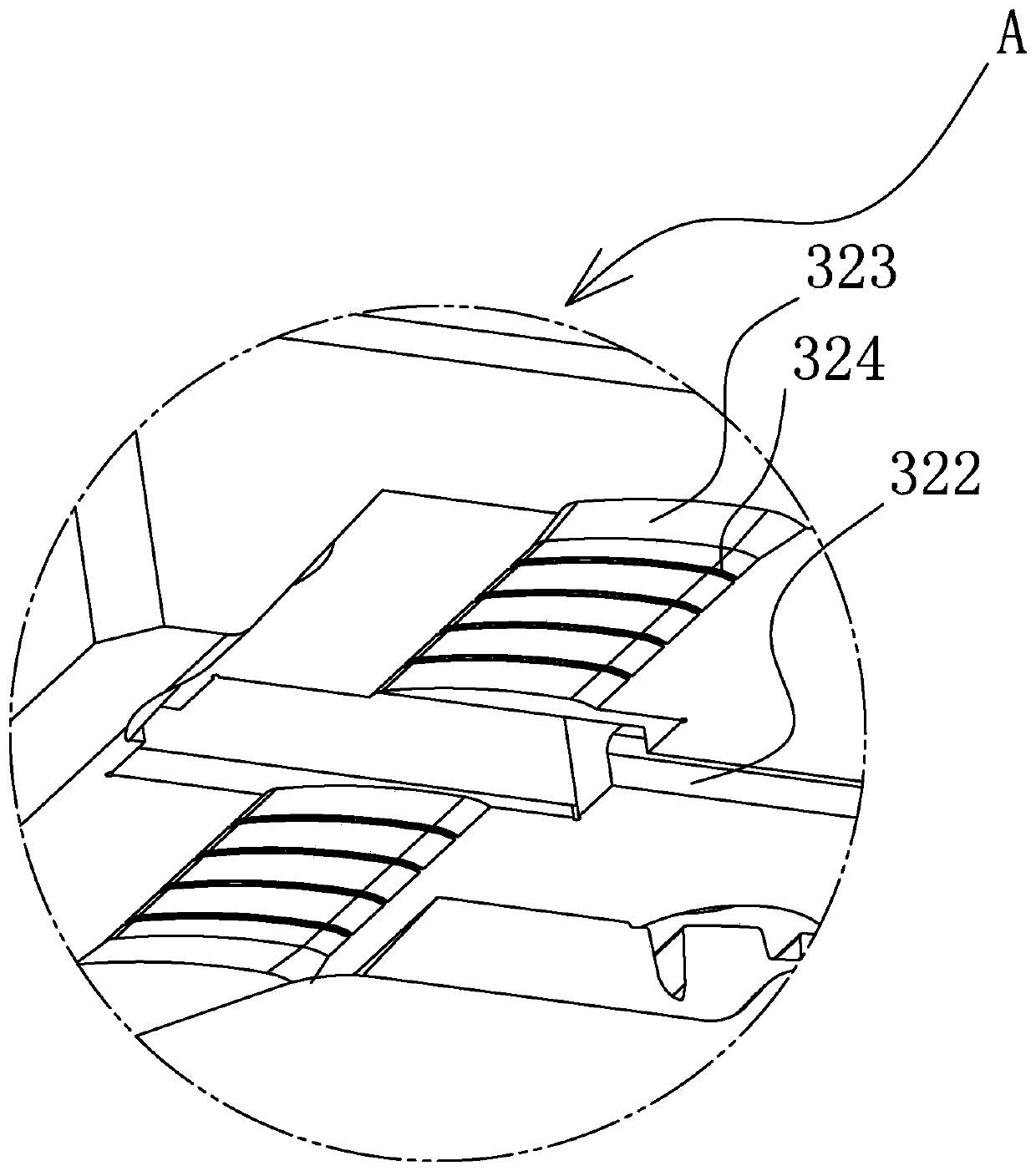

[0026] Such as Figure 1 to Figure 5 As shown, a bending die single cylinder intermediate cutting mechanism provided by the present invention includes: a frame 100, a power source 200 is connected to one end, and a pressing assembly 300 is connected to the output end of the power source 200, wherein, when pressing Below the assembly 300 is provided a traverse assembly 400 which is wedge-cooperated with the pressing assembly 300 , and the traverse assembly 400 is provided with a cavity 411 matching the shape of the workpiece to be cut.

[0027] When using the cutting mechanism, its working principle is: the long-span strip-shaped workpiece is embedded on the traversing assembly 400, and then the power source 200 drives the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com