A full-dry loose tube excess length control device

A control device and loose tube technology, applied in the field of optical cable manufacturing, can solve the problems of inability to meet process and use requirements, unfavorable tube material crystallization, affecting optical fiber transmission performance, etc. The effect of processing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

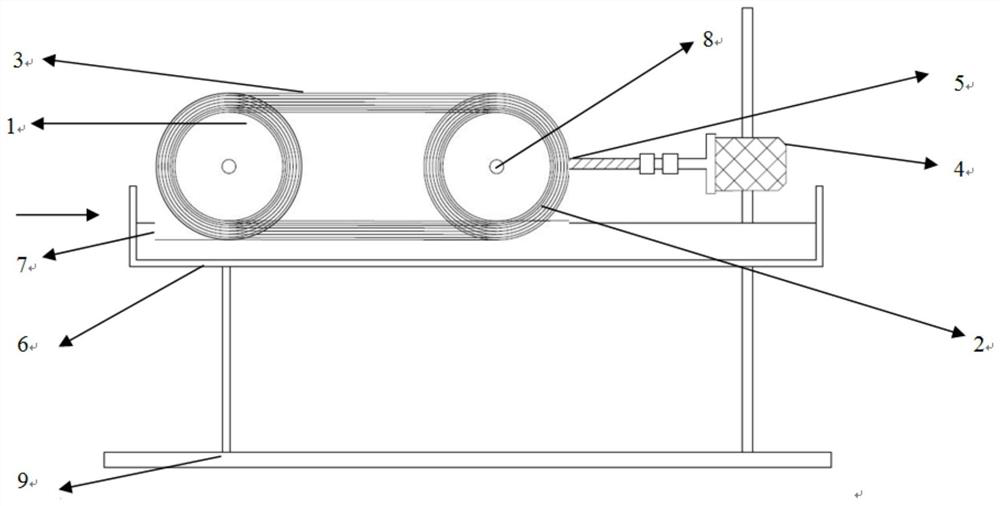

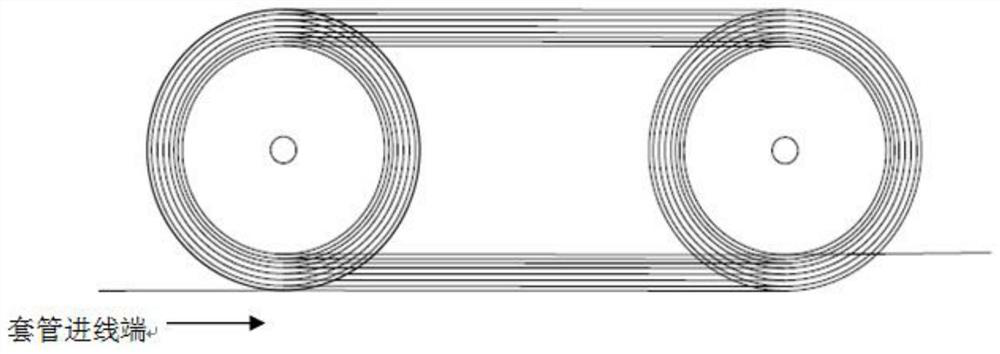

[0019] The present invention will be further described below in conjunction with the accompanying drawings and embodiments. Including a frame 9, a cooling water tank 6 is installed on the frame for cooling and shaping the optical fiber loose tube 3, the cooling water 7 in the water tank is immersed in the optical fiber loose tube in real time, and the water volume control unit is used to control the water volume of the water tank 6 , to ensure that the cooling water in the water tank can submerge the loose tube of the optical fiber in real time. A variable-diameter main traction pulley 1 and a variable-diameter splitting pulley 2 are correspondingly installed above the cooling water tank, and the variable-diameter main traction pulley and the variable-diameter splitting pulley are separated by a certain distance along the traction direction, that is, the horizontal direction. The variable-diameter main traction wheel is a driving wheel, which is used to pull the loose tube and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com