An energy-saving vertical mill rotary air lock feeder

An air-locking feeder and energy-saving technology, which is applied in the field of energy-saving vertical mill rotary air-locking feeders, can solve the problems of inconvenient installation and adjustment, high energy consumption of the air feeder, and achieve the improvement of direct heat discharge, The effect of reducing energy consumption and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

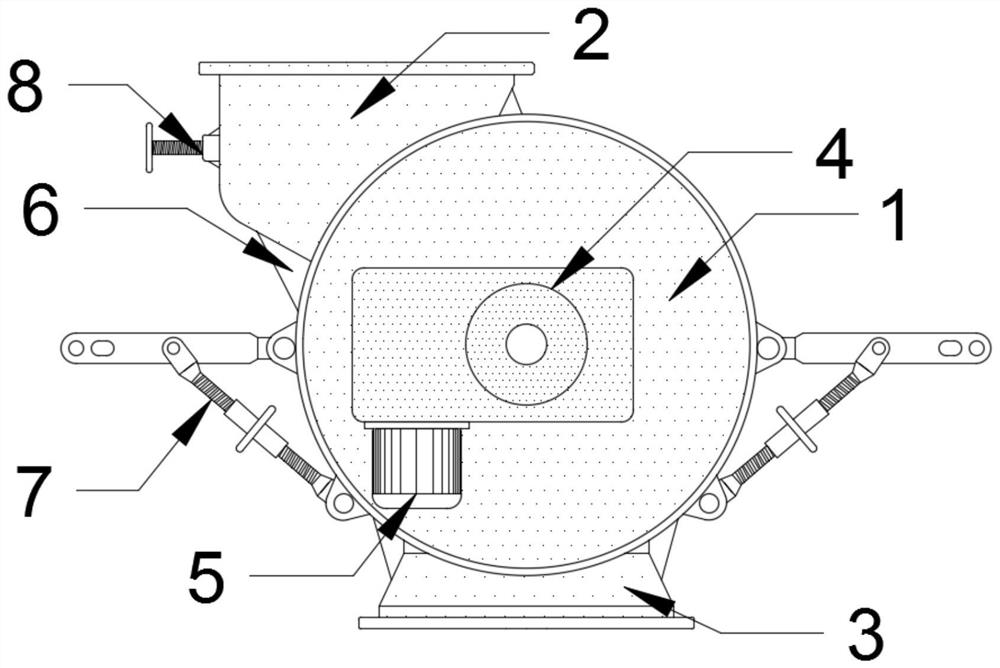

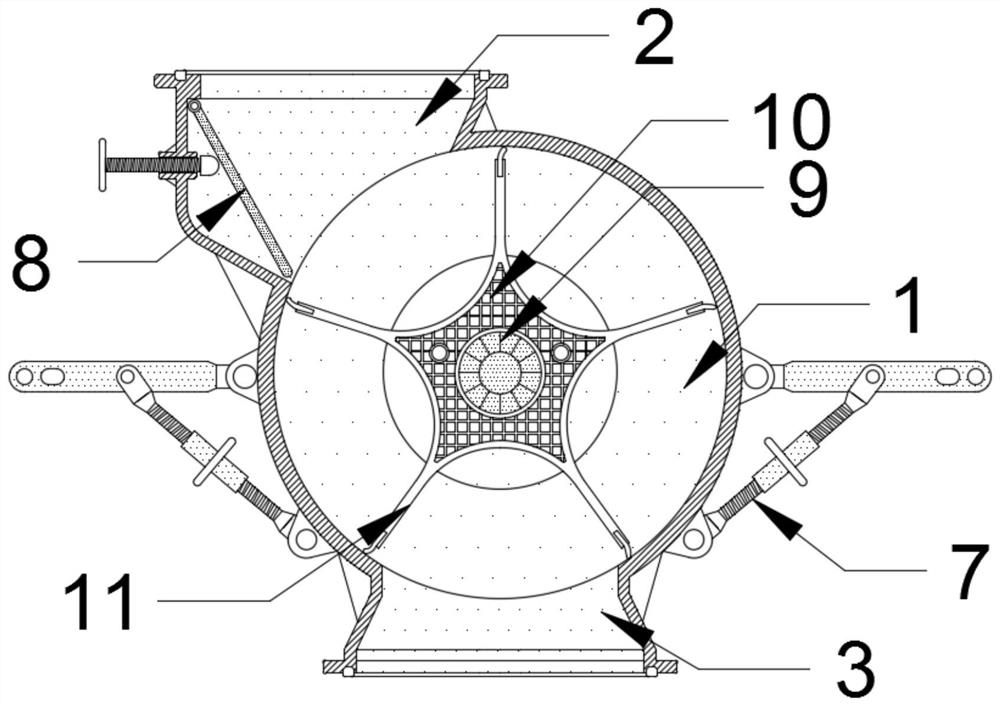

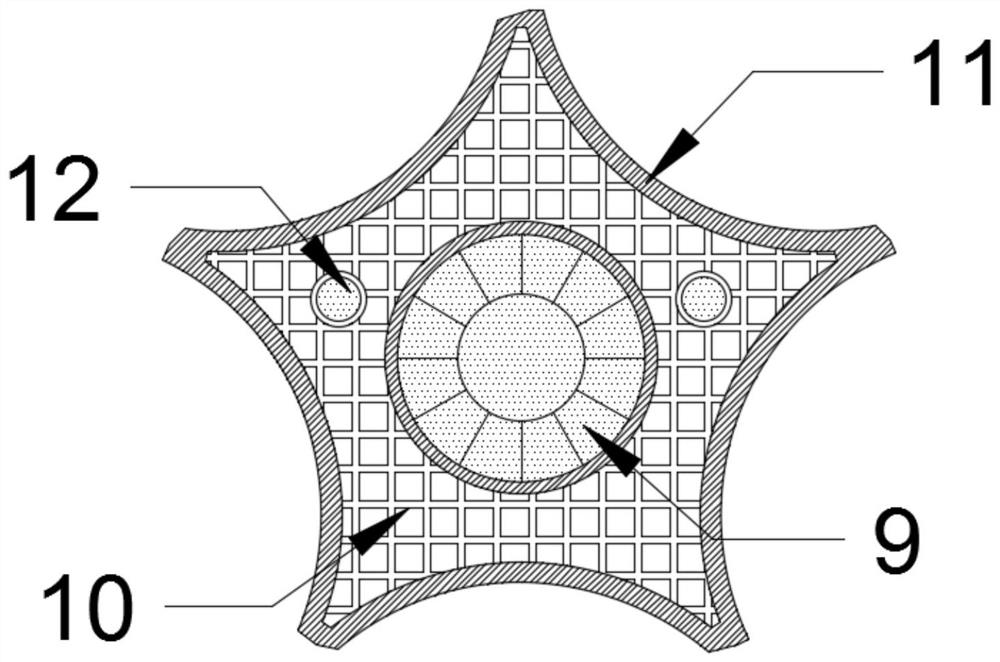

[0023] Such as Figure 1-2 As shown, this specific embodiment adopts the following technical solutions: an energy-saving vertical mill rotary airlock feeder, including a casing 1, a feed hopper 2, a discharge hopper 3, a reducer 4, a motor 5, a mounting mechanism 7, Feed adjustment mechanism 8, rotor 9 and impeller 11, the rotor 9 is installed in rotation inside the casing 1, the impeller 11 is fixed on the outside of the rotor 9, and the impeller 11 is pentagonal, and the top side of the casing 1 is fixed A feed hopper 2 is connected, and a discharge hopper 3 is fixedly connected to the center of the bottom of the casing 1. A feed adjustment mechanism 8 is installed on one side of the feed hopper 2, and a mounting mechanism 7 is symmetrically installed on the outer wall of the casing 1. The outer side of the casing 1 is located at the end of the rotating shaft of the rotor 9, and a reducer 4 is installed, and the bottom of the reducer 4 is equipped with a motor 5 for transmis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com