An exhaust device for hydraulic jump trowel in circulating water tank and its application

A technology of circulating water tank and exhaust device, which is used in measuring devices, testing of machine/structural components, instruments, etc., can solve problems such as adverse effects of equipment, and achieve the effects of smoothing water waves, suppressing water waves, and removing air bubbles.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

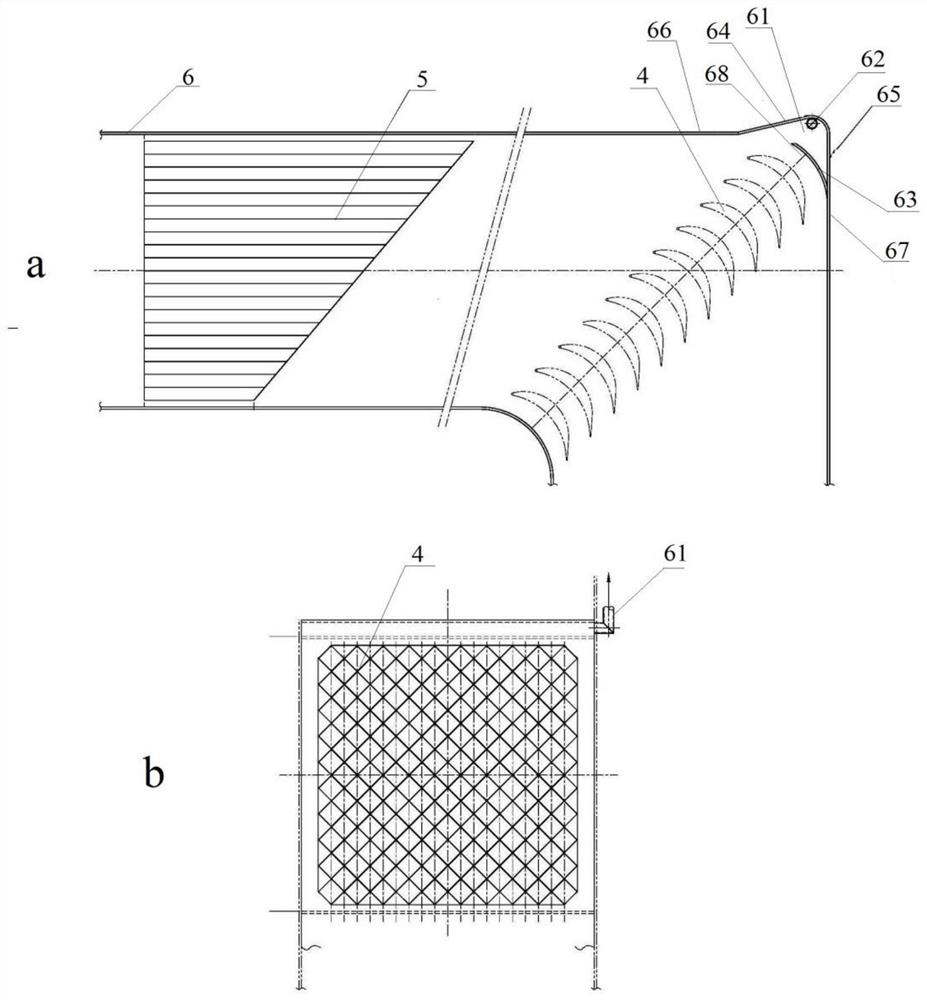

[0027] This embodiment relates to an exhaust device of a preferred structural form for a hydraulic jump trowel in a circulating water tank.

[0028] Such as Figure 1 ~ Figure 3 As shown, the exhaust device for the hydraulic jump trowel of the circulating water tank provided by this embodiment is generally composed of the grille 5 and the corner structure at the first elbow 68 of the water dividing plate arranged behind the grille 5 61, and the exhaust pipeline arranged between the two sides of the first elbow 68 of the water diversion plate and the gas collection box on the upper part of the tank body, through the above structure, the air bubbles are separated through the pipeline and collected through the exhaust pipeline Arranged on the air collecting box on the upper part of the tank body, so as to achieve the purpose of eliminating air bubbles in the water flow.

[0029] In this embodiment, the hydraulic jump trowel is located downstream of the test section 8, and the en...

Embodiment 2

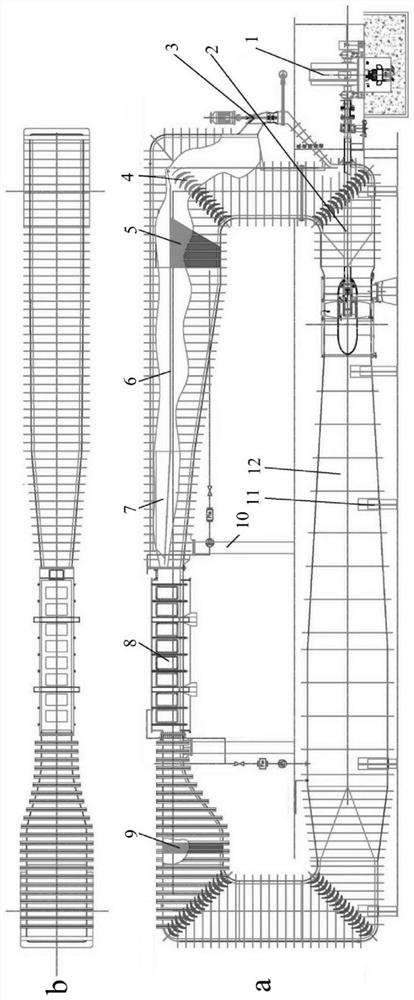

[0033] This embodiment is a circulating water tank hydraulic system containing the free liquid surface of the exhaust device for the hydraulic jump trowel of the circulating water tank described in embodiment 1.

[0034] Such as figure 2 As shown, the hydraulic system of the circulating water tank includes a main motor 1 connected by pipelines, a main circulation pump 2, an auxiliary pump 3, a corner deflector 4, a grille 5, a water dividing plate 6, an energy dissipation plate 7, a test section 8, The honeycomb 9, the tank body 12; the water dividing plate 6 is provided with a corner structure 61 for collecting air bubbles at the first elbow 68 of the water dividing plate; the water tank body 12 is installed on the base 11, and passes through the column 10 and test A fixed connection is made downstream of section 8. The connection methods of the above-mentioned devices can be arranged with reference to conventional methods in the field.

[0035] It can be seen from the abo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com