Grease depositing tank

A sedimentation tank and oil technology, applied in the direction of oil/fat refining, fat production, etc., can solve the problems of filter plate clogging, reduce the quality of pepper oil, equipment can not be used normally, etc., and achieve the effect of increasing the contact area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

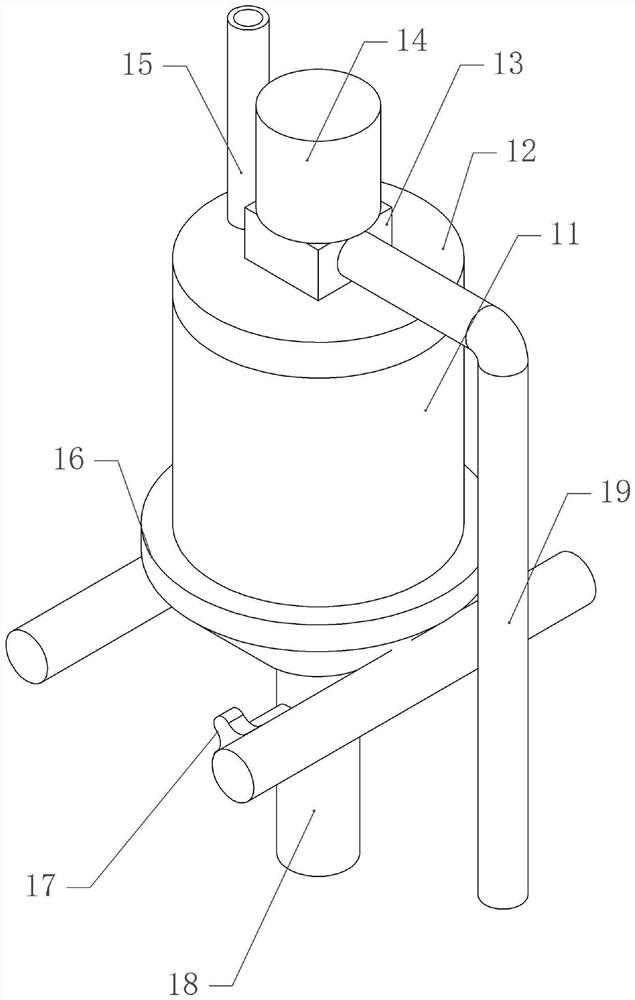

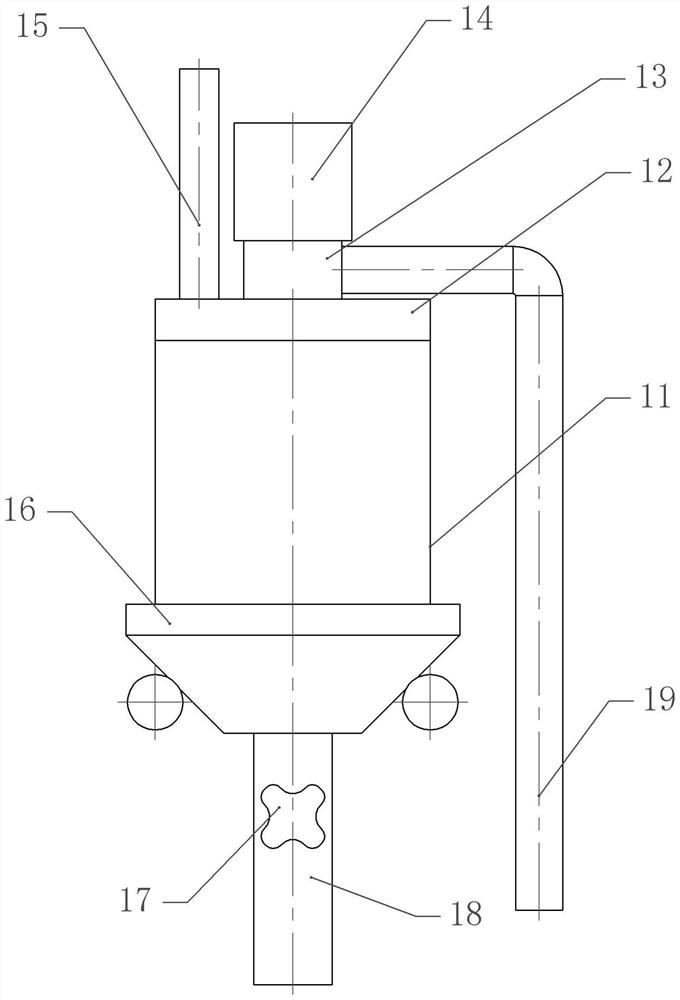

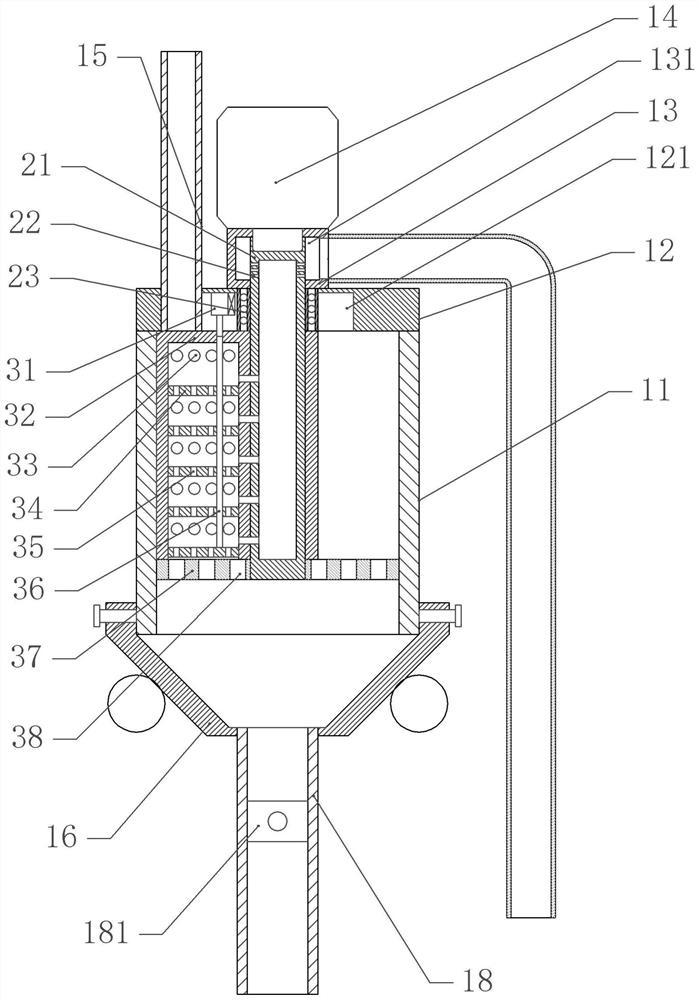

[0036] A kind of grease sedimentation tank, as attached figure 1 , attached figure 2 And attached image 3 As shown, it includes a frame and a tank body 11 fixed by bolts on the frame, the upper opening of the tank body 11, and a cover body 12 for closing the opening is fixed by bolts on the tank body 11.

[0037] In this embodiment, the feed pipe 15 is fixed with bolts on the cover body 12, the support part 13 is fixed on the cover body 12, and the support part 13 has a cavity 131, and also includes a waste discharge structure, which includes a negative pressure pump And the waste discharge pipe communicated with the negative pressure pump, the waste discharge pipe communicates with the cavity 131 .

[0038] Bolts on the support part 13 are fixed with a driving part, the driving part is a motor 14, the output shaft of the driving part is coaxially fixedly connected with a rotating shaft 21 which is rotatably connected with the cover plate, and a ball bearing 23 is set on t...

Embodiment 2

[0047] The difference between embodiment two and embodiment one is that, as attached Figure 4 As shown, the bottom of the rotating shaft 21 is fixed with a permeable layer 46, and the bottom of the permeable layer 46 is provided with a closing plate 44. The closing plate 44 is rotatably connected with the tank body 11 by a torsion spring, and the bottom of the closing plate 44 is hinged with a connecting rod 42. The rod 42 is hinged with the spoiler 181, and the discharge pipe is fixedly connected with a guide pipe 43, and the guide pipe 43 is vertically slidably connected with the connecting pipe.

[0048] In this embodiment, both sides of the closing plate 44 are provided with a second arc-shaped surface 45, and both sides of the spoiler 181 are provided with a first arc-shaped surface 41, so that the closing plate 44 is in line-surface contact with the tank body 11 , can reduce the frictional resistance between the closing plate 44 , the spoiler 181 and the side wall, so t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com