Soil heavy metal detection systems

A detection system and heavy metal technology, which is applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of large resource consumption and slow speed of soil heavy metal detection technology, and achieve the effect of reducing energy consumption and saving resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

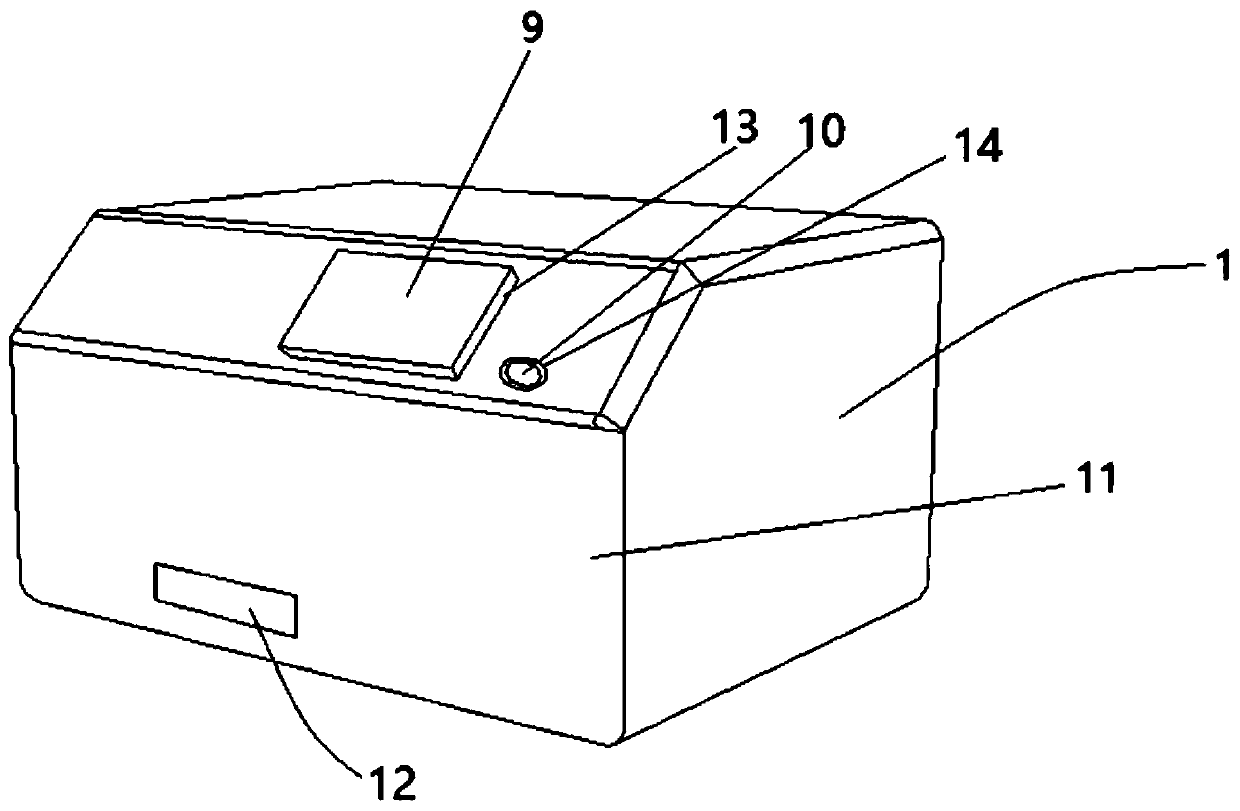

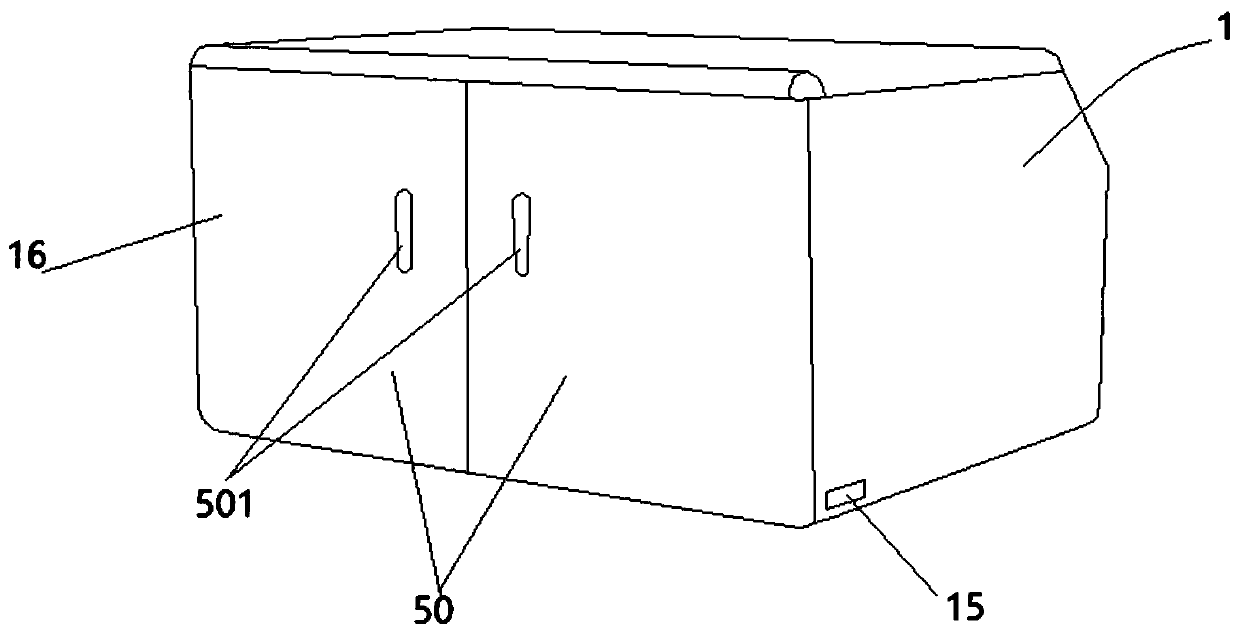

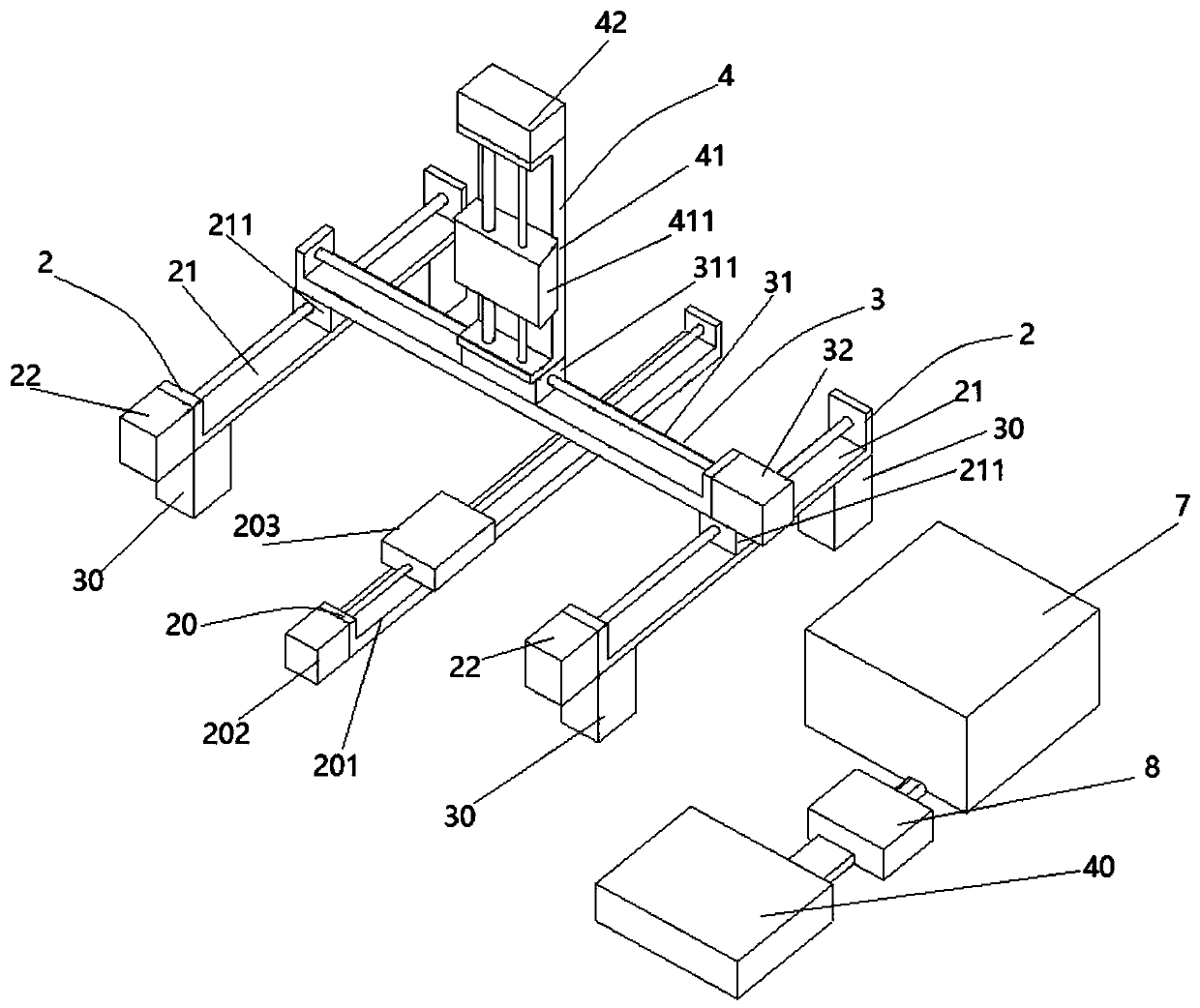

[0053] see Figure 1~6 , a soil heavy metal detection system provided by the present invention, the system includes: a chassis 1, the lower part of the front panel 11 of the chassis 1 is provided with a sample tray outlet 12; 1. Two Y-axis linear slides 21 on the inner surface of the bottom plate. The two Y-axis linear slides 21 are respectively connected to a Y-axis drive motor 22; The X-axis linear slide 31 is perpendicular to each other. The two ends of the bottom surface of the X-axis linear slide 31 are respectively erected on the Y-axis slide 211 of a Y-axis linear slide 21. The X-axis linear slide 31 is connected by transmission. There is an X-axis driving motor 32; the Z-axis moving assembly 4 includes a Z-axis linear slide table 41 vertically arranged on the upper surface of the X-axis slide seat 311 of the X-axis linear slide table 31, and the Z-axis linear slide table The Z-axis sliding seat 411 of 41 is set towards the front panel 11 of the box body 1, and the Z-a...

Embodiment 2

[0077] A pallet moving assembly 20 is mounted on the inner surface of the bottom plate of the chassis 1 between the two Y-axis linear slides 21. The pallet moving assembly 20 includes a pallet linear slide 201, and the pallet linear slide 201 is along the length of the Y-axis linear slide 21. Direction setting, the tray linear slide 201 is connected with a tray drive motor 202; the bottom surface of the sample tray 6 is set on the tray slide 203 of the tray linear slide 201; the tray drive motor 202 communicates with the control assembly 8 And it is electrically connected with the power supply unit 7 .

[0078] Further, a position sensor (not shown) is provided at the end of the tray linear slide 201 close to the sample tray outlet 12 , and the position sensor is connected to the control assembly 8 in communication.

[0079] The design of the tray moving component 20 can realize the front and rear sliding of the sample tray 6 inside the cabinet 1, realize the automatic transmi...

Embodiment 3

[0083] A vibration-damping support seat 30 is vertically provided at both ends of the bottom surface of the Y-axis linear slide 21 in the longitudinal direction.

[0084] The design of the vibration-damping support seat 30 can provide vibration-damping support for the Y-axis moving assembly 2, so that the Y-axis moving assembly 2 can strongly support the X-axis moving assembly 3 and the Z-axis moving assembly 4, thereby improving the service life.

[0085] All the other are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com