A multi-point controlled pneumatic keyboard and its keycap precise injection molding method

A multi-point control and keyboard technology, applied in the direction of electrical components, electric switches, circuits, etc., can solve problems such as slow recovery speed, insensitivity to pressing contacts, offset, etc., and achieve the effect of improving accuracy and sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

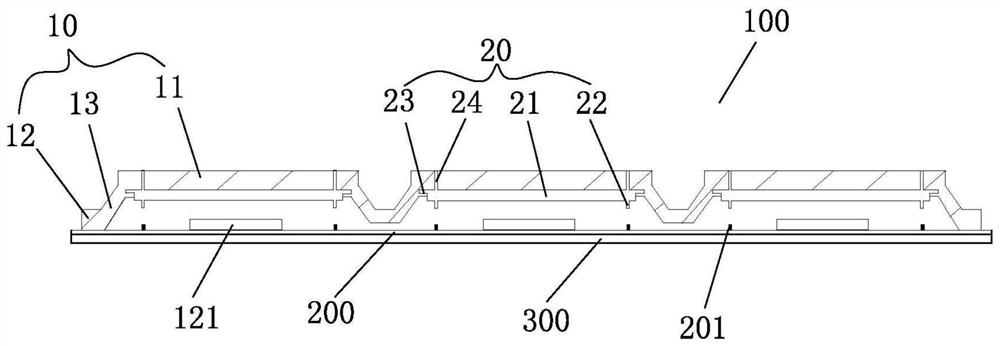

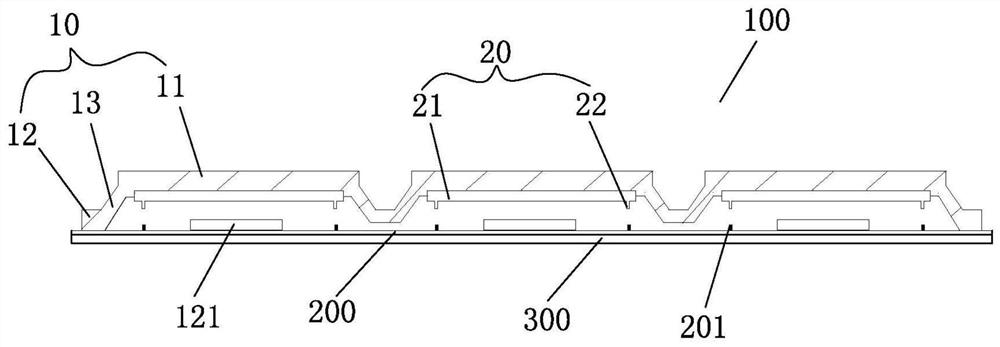

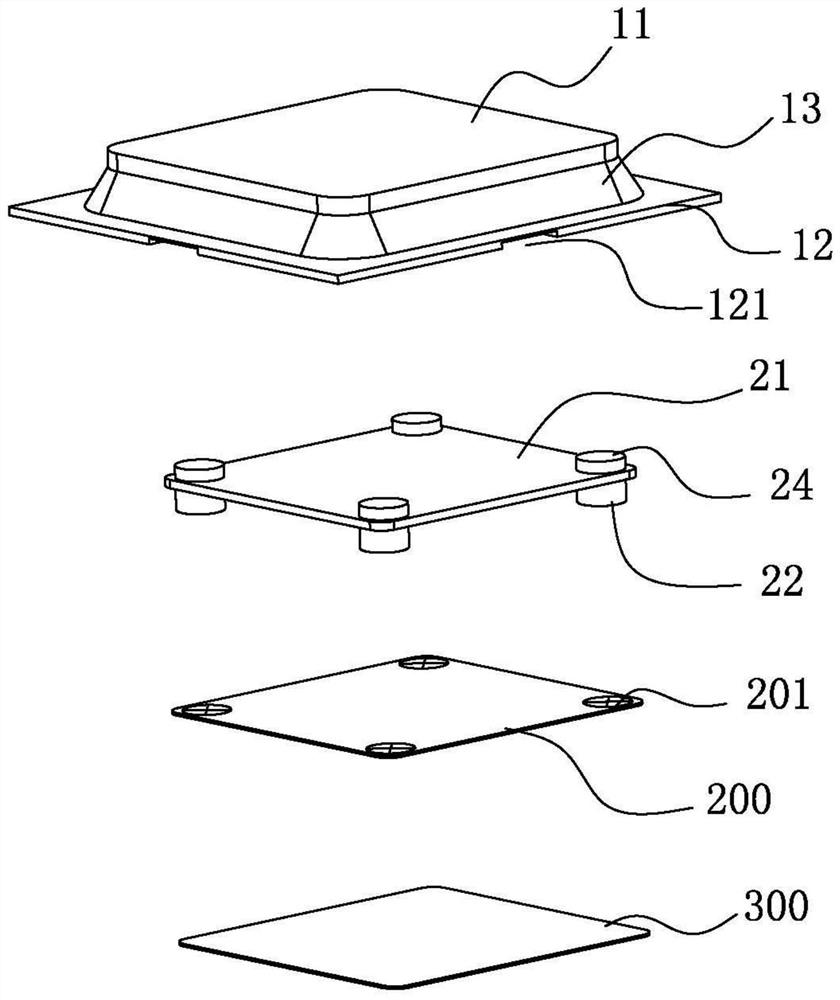

[0037] Such as Figure 1-6 As shown, a pneumatic keyboard with multi-point control includes an integrated key cap 100, a printed circuit film 200 positioned under the integrated key cap 100, and a keyboard bottom plate 300 supported under the printed circuit film 200,

[0038] The one-piece key cap 100 is composed of integral soft rubber parts and several hard parts 20 integrally formed by injection molding, wherein the integral soft rubber parts are connected by several soft rubber key units 10, each soft rubber key The unit 10 includes a soft rubber key surface 11, a soft rubber base 12, and a soft rubber support body 13 connecting the soft rubber base 12 and the soft rubber key surface 11;

[0039] The hard part 20 includes a convex hard plate 21, the shape and size of the convex hard plate 21 are matched with the soft rubber button surface 11 and integrally injection molded on the bottom surface of the soft rubber button surface 11; The edge of the bottom surface of the sha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com