Improved extruder

A technology of puffing machine and puffing chamber, which is applied in food forming, food science, application, etc. It can solve the problems of shedding, high impact force of pressure ring, loose fastening structural parts, etc., and expand the range of pressure adjustment and application range Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

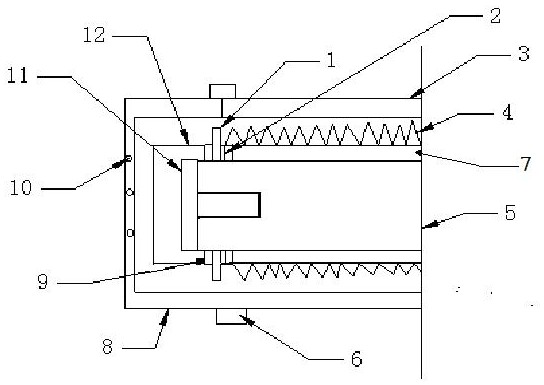

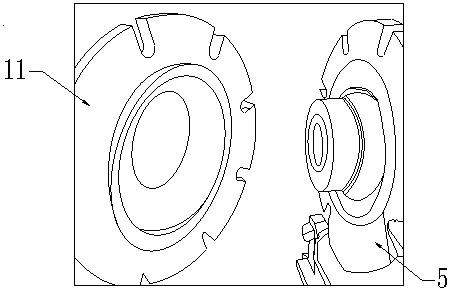

[0025] Taking the TDPH-260 extruder as an example, an improvement is made on the basis of this type of extruder. For the improved extruder in this embodiment, please refer to Figure 1-4 As shown, the extruder includes an expansion chamber 3 and a conditioner: the expansion chamber 3 is provided with a main shaft 5 and a screw 7 along its length, and the outer wall of the screw 7 is provided with a spiral protrusion 4; A feeder is provided on the conditioner, and a feeding auger is provided in the feeder: a bolt 11 is provided in the main shaft 5, and the bolt 11 extends out of the port of the main shaft 5, and the outer end of the bolt It is a structure that cooperates with the nut, and the nut 12 covers the end of the bolt and the end of the main shaft 5 to a position close to the second gasket 9;

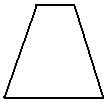

[0026] The longitudinal section of the spiral protrusion 4 has a trapezoidal structure: the trapezoidal structure is a right-angled trapezoidal or approximately right-angled trap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com