Double-spring pressure reducing valve

A pressure reducing valve and double spring technology, applied in the field of double spring pressure reducing valve, can solve the problems of small elasticity, troublesome adjustment, limited sealing effect, etc., and achieve the effect of improving elasticity, increasing range and good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

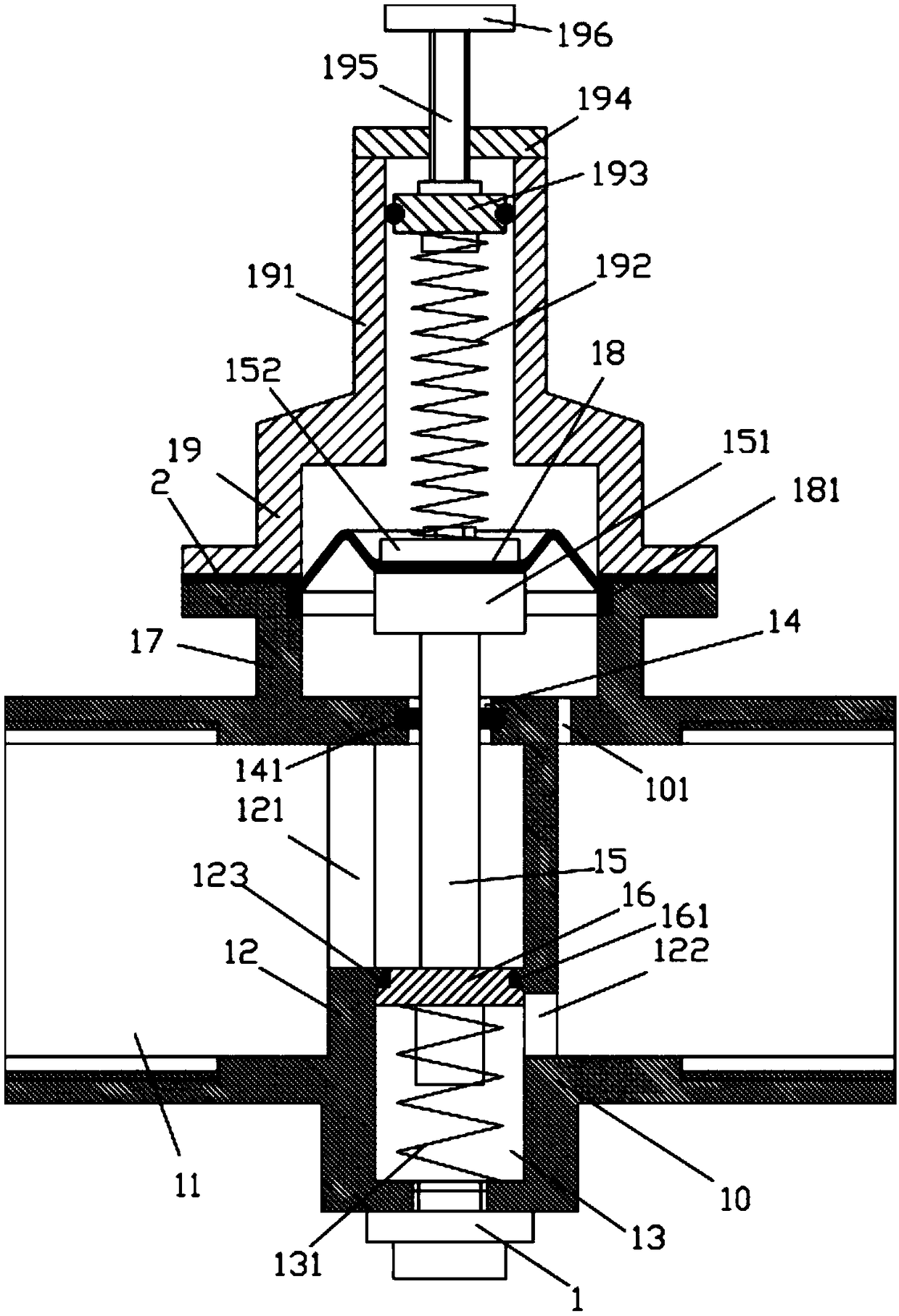

[0016] Examples, see e.g. figure 1 As shown, a double spring pressure reducing valve includes a valve body 10, the left end and the right end of the valve body 10 are formed with a flow connecting pipe part 11, and the middle part of the valve body 10 is formed with a cylindrical sleeve body 12, and the cylindrical sleeve body 12 The top and bottom ends of the valve body 10 are formed on the top and bottom surfaces of the valve body 10. The upper left side of the cylindrical sleeve body 12 has an upper through groove 121, and the lower right side of the cylindrical sleeve body 12 is formed with a lower through groove 122. The inner bottom surface of the valve body 10 at the bottom surface of the sleeve body 12 is formed with a cylindrical extension sleeve body part 13 extending downward, and the inner top surface of the valve body 10 at the top of the cylindrical sleeve body 12 is formed with a through hole 14, and the vertical rod 15 is inserted into the through hole 14, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com