Hydraulic machine

A technology of hydraulic presses and hydraulic cylinders, applied in the field of hydraulic presses with high and low pressure automatic conversion, which can solve the problems of inability to adjust hydraulic pressure, inconvenience for staff to carry, increase in weight and volume, and achieve compact structure, enhanced function diversity, and improved use. The effect of longevity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

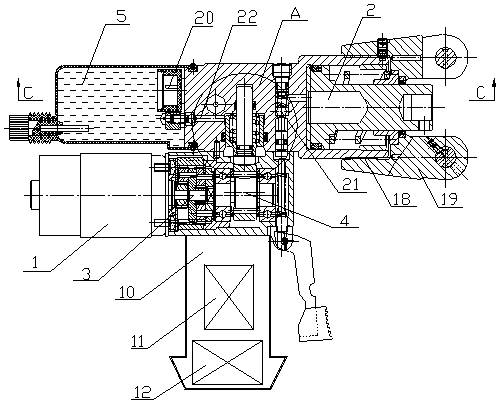

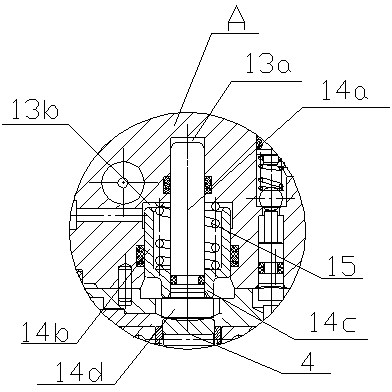

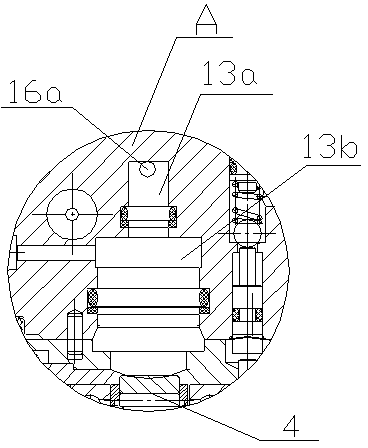

[0020] Such as Figure 1 to Figure 7 As shown, a hydraulic machine includes a housing 10, a drive motor 1, an oil pump, an oil tank 5, and a hydraulic cylinder 2. The oil pump driven by the drive motor 1 is a plunger pump, and the output shaft of the drive motor 1 is connected to a planetary gear transmission 3 The power input shaft of the planetary gear transmission 3 and the power output shaft of the planetary gear transmission 3 are connected to the camshaft 4 of the plunger pump. The camshaft 4 is provided with a plunger 14 that can perform piston movement in the pump chamber 13, and the camshaft 4 and the plunger 14 form a cam Tappet mechanism, its pump cavity 13 top is set as high-pressure cavity 13a, and pump cavity 13 bottom is set as low-pressure cavity 13b, and the cross-sectional radius of low-pressure cavity 13b is greater than the cross-sectional radius of high-pressure cavity 13a, and the plunger in described pump cavity 13 14 According to the size of the high an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com