Dustproof cover for car coupler device and preparation method of dustproof cover

A dust cover and coupler technology, applied in the field of dust cover, can solve problems such as decoupling accidents, shorten the service life of couplers, etc., achieve the effects of reducing frictional resistance, improving chemical stability, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

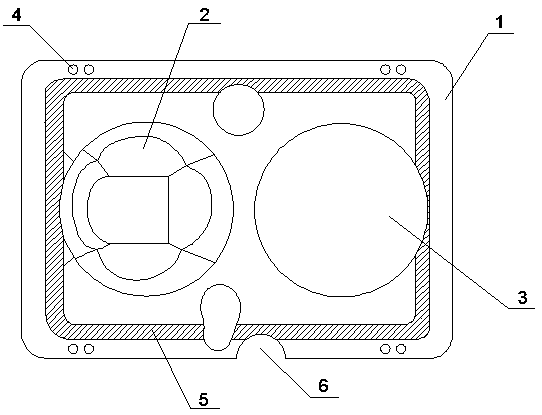

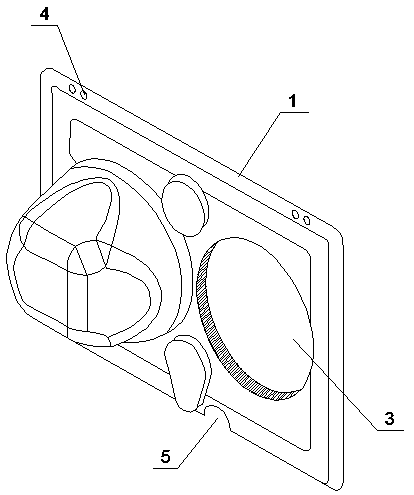

[0030] This embodiment provides a dust cover for a coupler device, including a dust cover body 1, see figure 1 A lip 6 is opened in the middle of one side of the dust cover body 1, and four corners of the dust cover body 1 are provided with mounting holes 4 for fixing the dust cover body 1 to the vehicle body.

[0031] A bowl-shaped groove 2 is opened at the left end of the upper end surface of the dust cover body 1, and a circular groove 3 is opened at the right end of the lower end surface of the dust cover body 1, see figure 1 , The circular groove 3 and the bowl-shaped groove 2 are located on the same horizontal line. A circular groove 32 and an elliptical groove 3 are also provided in the middle of the upper end surface of the dust cover body 1. The diameter of the circular groove 32 is smaller than the diameter of the circular groove 3.

[0032] Four rectangular grooves are provided on the lower end surface of the dust cover body 1. The four rectangular grooves are respectivel...

Embodiment 2

[0041] This embodiment provides a dust cover for a coupler device, including a dust cover body 1, see figure 1 A lip 6 is opened in the middle of one side of the dust cover body 1, and four corners of the dust cover body 1 are provided with mounting holes 4 for fixing the dust cover body 1 to the vehicle body.

[0042] A bowl-shaped groove 2 is opened at the left end of the upper end surface of the dust cover body 1, and a circular groove 3 is opened at the right end of the lower end surface of the dust cover body 1, see figure 1 , The circular groove 3 and the bowl-shaped groove 2 are located on the same horizontal line. A circular groove 32 and an elliptical groove 3 are also provided in the middle of the upper end surface of the dust cover body 1. The diameter of the circular groove 32 is smaller than the diameter of the circular groove 3.

[0043] Four rectangular grooves are provided on the lower end surface of the dust cover body 1. The four rectangular grooves are respectivel...

Embodiment 3

[0052] This embodiment provides a dust cover for a coupler device, including a dust cover body 1, see figure 1 A lip 6 is opened in the middle of one side of the dust cover body 1, and four corners of the dust cover body 1 are provided with mounting holes 4 for fixing the dust cover body 1 to the vehicle body.

[0053] A bowl-shaped groove 2 is opened at the left end of the upper end surface of the dust cover body 1, and a circular groove 3 is opened at the right end of the lower end surface of the dust cover body 1, see figure 1 , The circular groove 3 and the bowl-shaped groove 2 are located on the same horizontal line. A circular groove 32 and an elliptical groove 3 are also provided in the middle of the upper end surface of the dust cover body 1. The diameter of the circular groove 32 is smaller than the diameter of the circular groove 3.

[0054] Four rectangular grooves are provided on the lower end surface of the dust cover body 1. The four rectangular grooves are respectivel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com