Automobile composite material energy absorption module

A technology of composite materials and automobiles, applied in the direction of bumpers, etc., can solve the problems of small plastic area and poor energy absorption effect, and achieve the effect of reducing maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

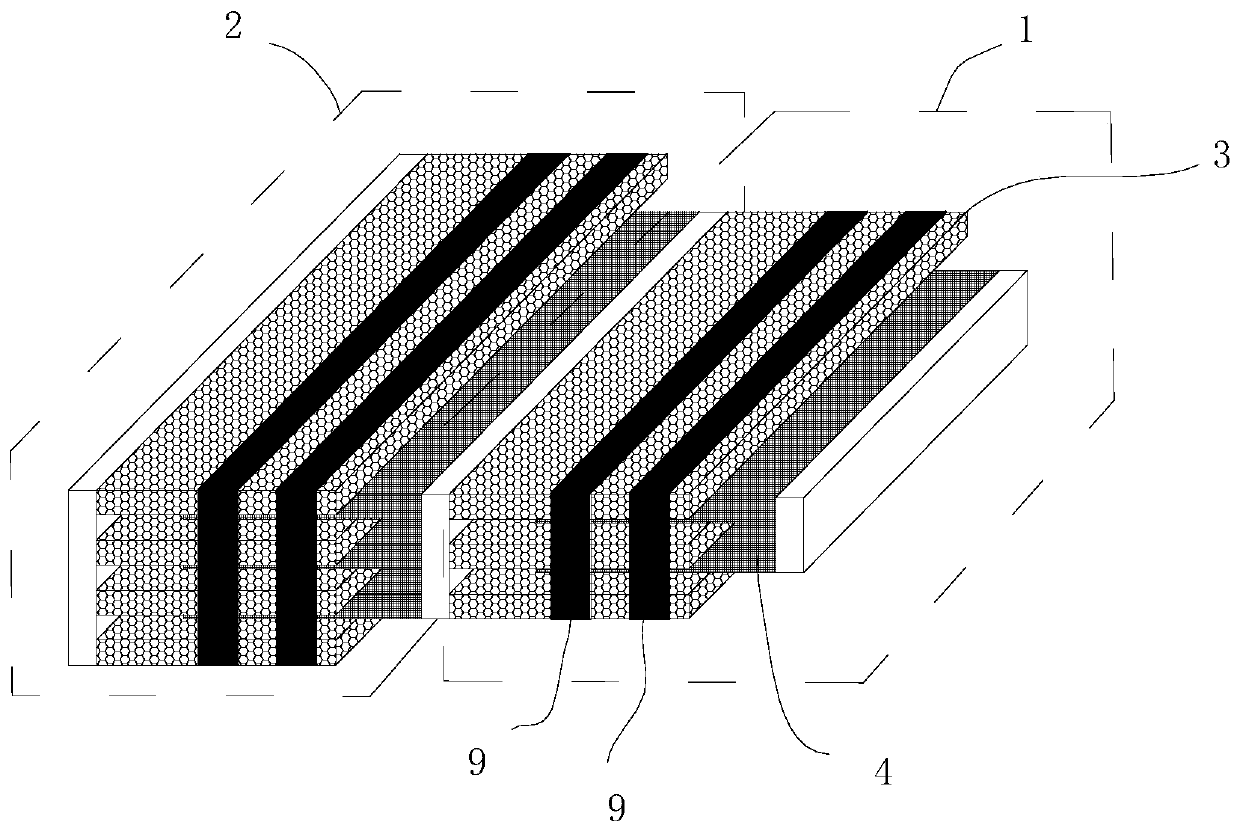

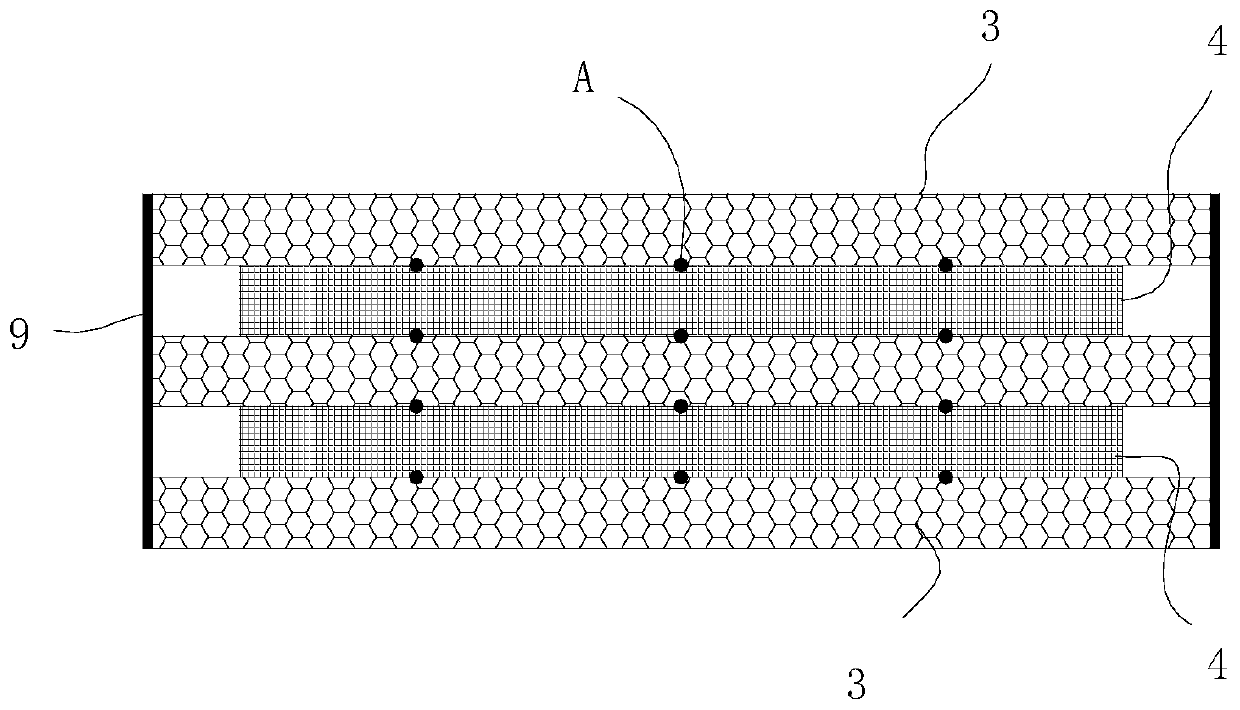

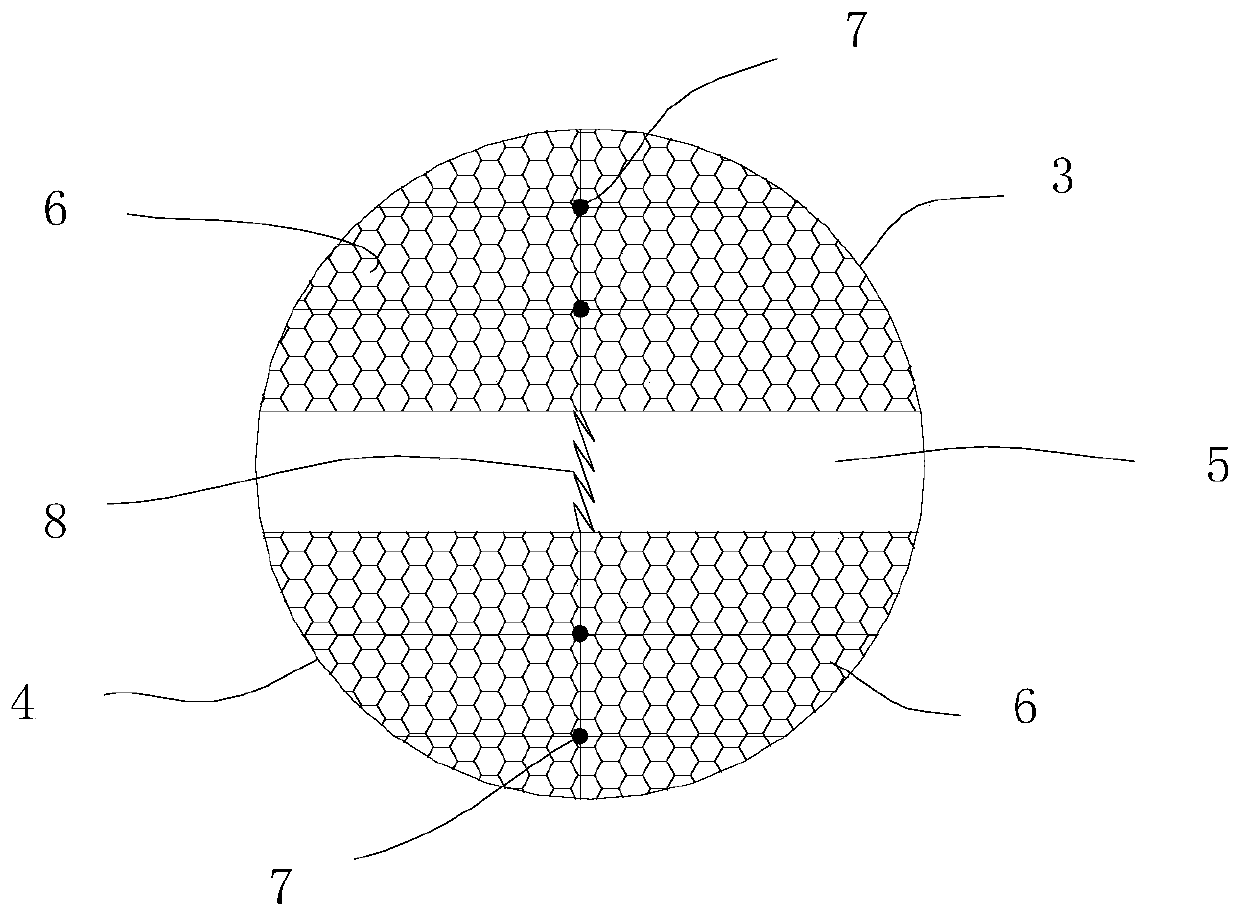

[0026] Such as Figure 1 to Figure 6 As shown, an energy-absorbing module made of composite materials for automobiles is provided with two adjacent first basic modules 1 and second basic modules 2 that can be used for frictional energy absorption and structural crushing energy absorption. The first base module 1 and the second base module 2 respectively comprise at least two first base layers 3 and second base layers 4 with an adjacent interface 5, the first base layer 3 and the second base layer at the adjacent interface 5 4 Relatively move under force and break apart structurally. The first base layer 3 and the second base layer 4 respectively include a base material 6 and a reinforcing material 7 arranged in the base material 6, and a flexible layer is provided between the first base layer 3 and the second base layer 4 at the adjacent interface 5. The connecting piece 8, the flexible connecting piece 8 is respectively connected to the reinforcing material 7 in the first ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com