Water guiding sleeve and no-clean washing machine

A washing machine and sleeve technology, applied in the field of washing machines, can solve the problems of low utilization rate of the inner space of the washing machine, inability to clean, and easy accumulation of dirt, etc., and achieve the effect of being suitable for popularization and use, significant effect, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

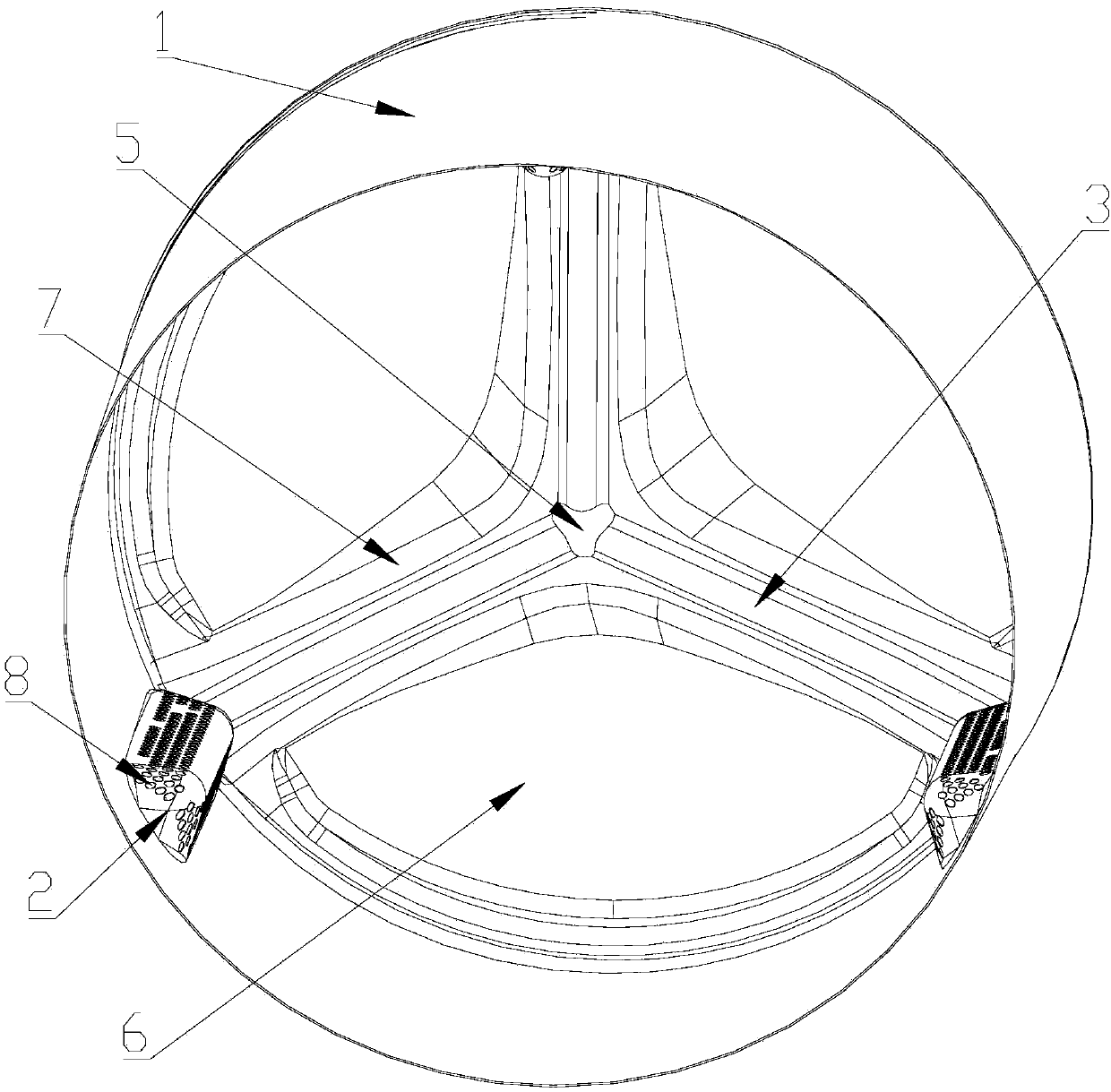

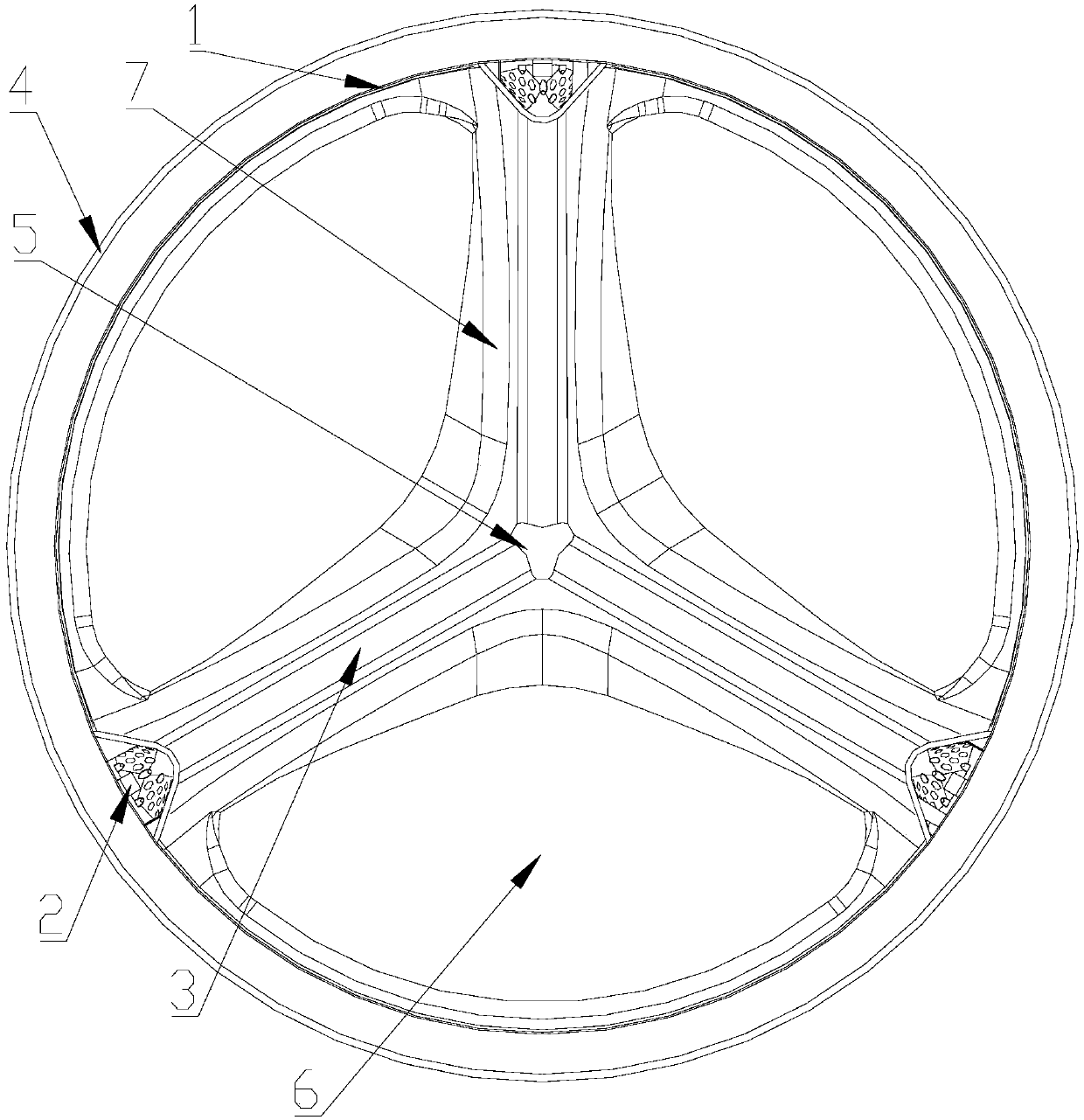

[0048] Such as Figure 1 to Figure 9 As shown, this embodiment introduces an inner cylinder applied to the no-cleaning washing machine of the present invention. The inner cylinder bottom 6 is arranged with a plurality of water guide channels 3 extending from the outer periphery to the center, and the center of the inner cylinder bottom 6 is provided with a The ends of each water guiding flow channel 3 are respectively connected to the central joint 5, and the rear end of the central joint 5 is provided with a water outlet interface 501 passing through the bottom of the inner cylinder 6, so that the washing water in the inner cylinder 1 is subjected to centrifugal force to flow through the water guiding flow. The channel 3 flows to the central joint 5 and then flows out of the inner cylinder 1 through the water outlet interface 501 .

[0049] Through the above setting, a central joint is set at the center of the inner cylinder bottom, and then all the water guide channels at th...

Embodiment 2

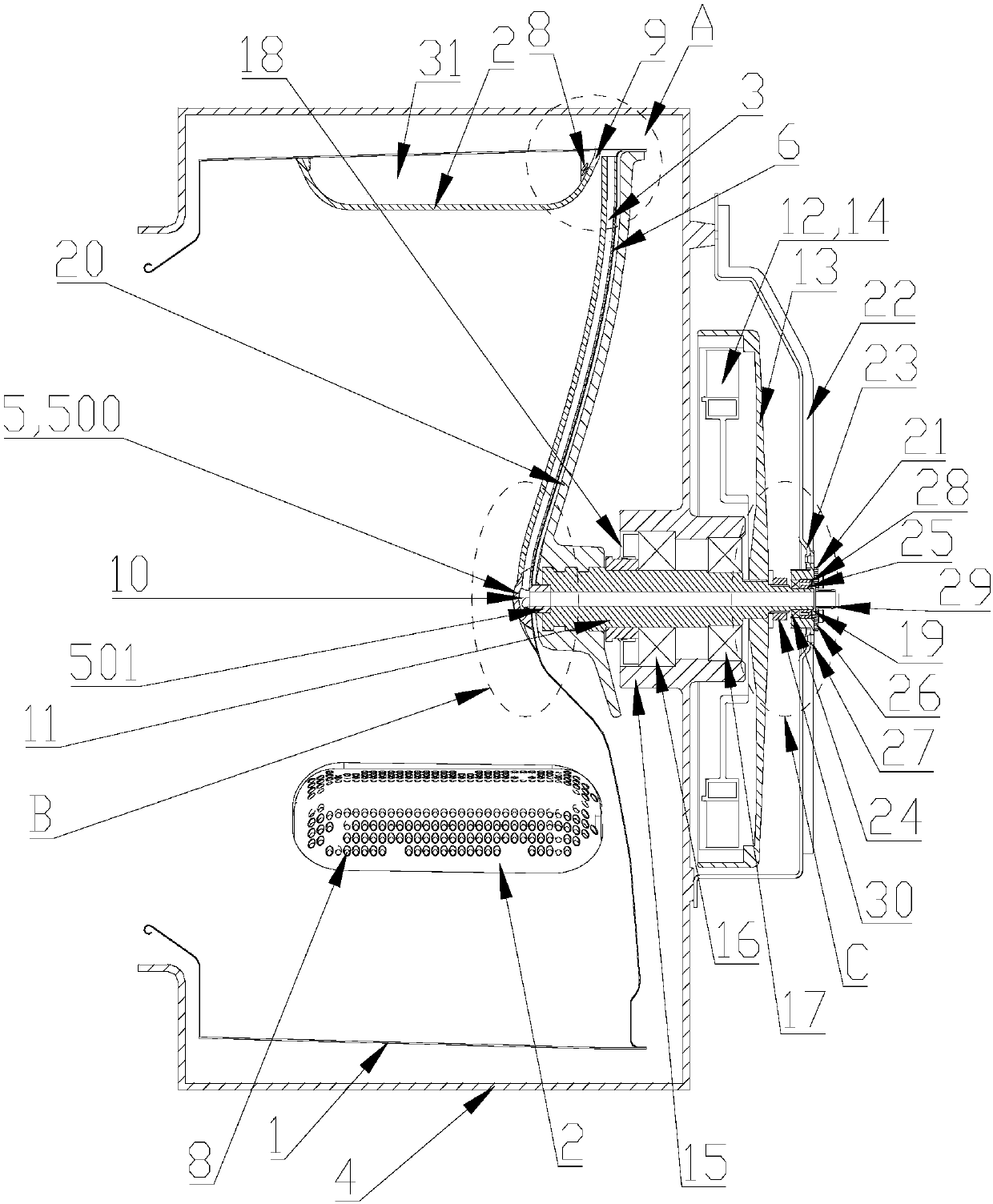

[0060] Such as Figure 1 to Figure 9 As shown, a water guide sleeve is introduced in this embodiment. A water outlet interface 501 is provided at the center of the bottom 6 of the washing machine. The first end of the water guide sleeve 11 is plugged and connected to the water outlet interface 501. , to guide the washing water flowing out of the inner cylinder 1 to flow along the water guide sleeve 11 to the drain pipe of the washing machine; The outer rotor 13 of the driving motor 12 of the washing machine is engaged and fixed, so that the outer rotor of the driving motor drives the inner cylinder 1 to rotate through the water guide sleeve 11 .

[0061]By setting the water guide sleeve on the rear side of the washing machine, the central through hole of the water guide sleeve forms a channel for the washing water flowing out of the inner cylinder, so that the washing water in the inner cylinder can be smoothly discharged along the water guide sleeve by centrifugal force ; Al...

Embodiment 3

[0071] Such as Figure 1 to Figure 9 As shown, a washing machine water outlet structure is introduced in this embodiment. A sealed water flow chamber 19 is fixedly installed on the rear side of the inner cylinder support member 4 of the washing machine. The water outlet joint 21 and the end of the water guide sleeve 11 rotating with the inner cylinder 1 extend into the water flow chamber 19 to discharge the washing water flowing out from the inner cylinder 1 along the water guide sleeve 11 .

[0072] By setting the water flow chamber on the back side of the washing machine, the water guide sleeve that guides the washing water to flow out and rotates with the inner cylinder is dynamically sealed with the water flow chamber, and then directly plugged with the washing machine drain pipe, avoiding water leakage. The problem of asynchronous rotation and inability to connect the water sleeve directly with the drainpipe, thereby achieving the purpose of smoothly draining the washing ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap