Fused salt electric-auxiliary thermal constant-parameter hot air heat exchanger

A technology of electric auxiliary heating and molten salt, applied in air heaters, fluid heaters, lighting and heating equipment, etc., can solve the problems of conflicting design concepts, inability to change the air side, etc., to achieve good use effects and enhance heat exchange. effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other.

[0028] The present invention will be described in detail below with reference to the accompanying drawings and examples.

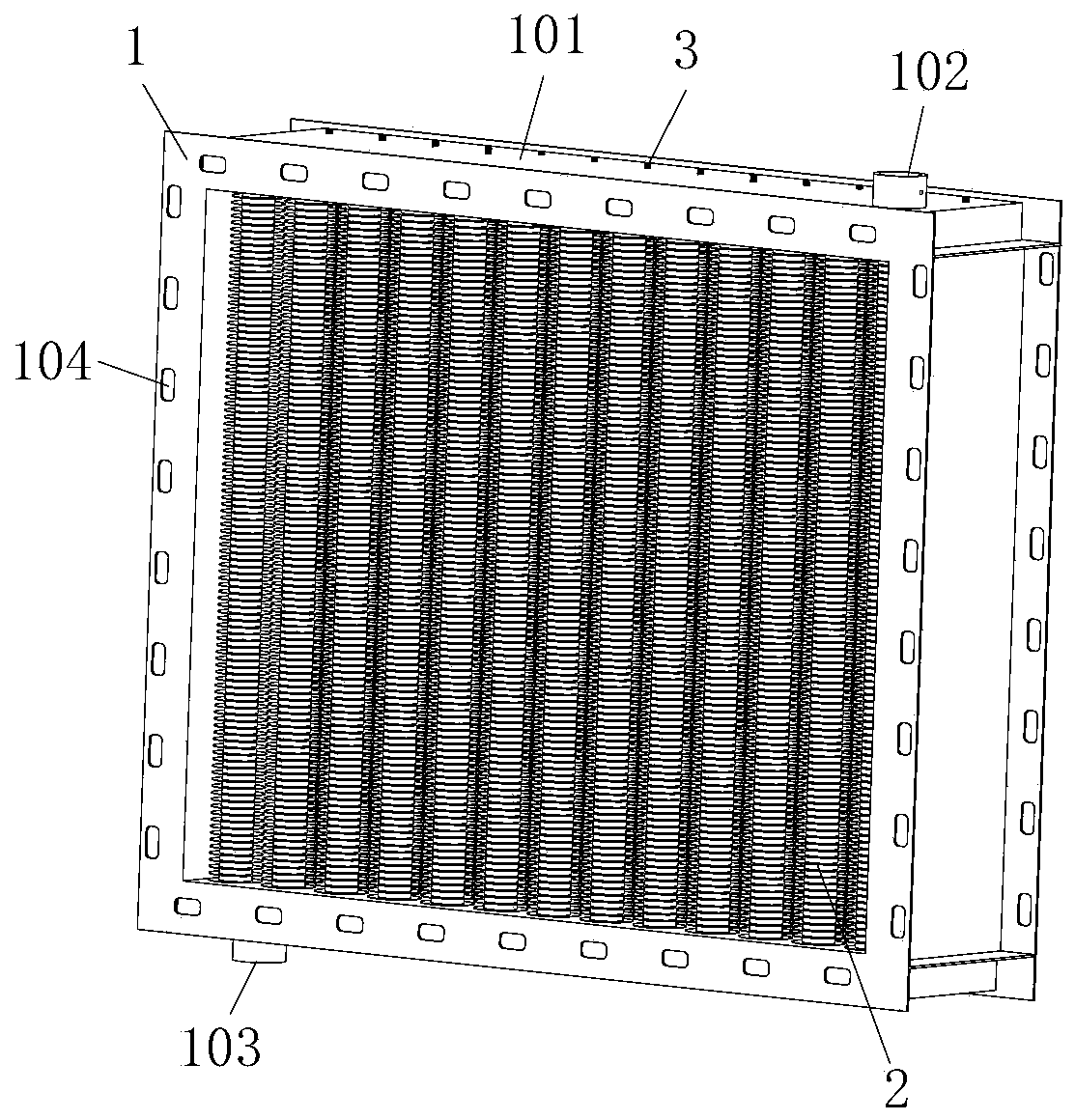

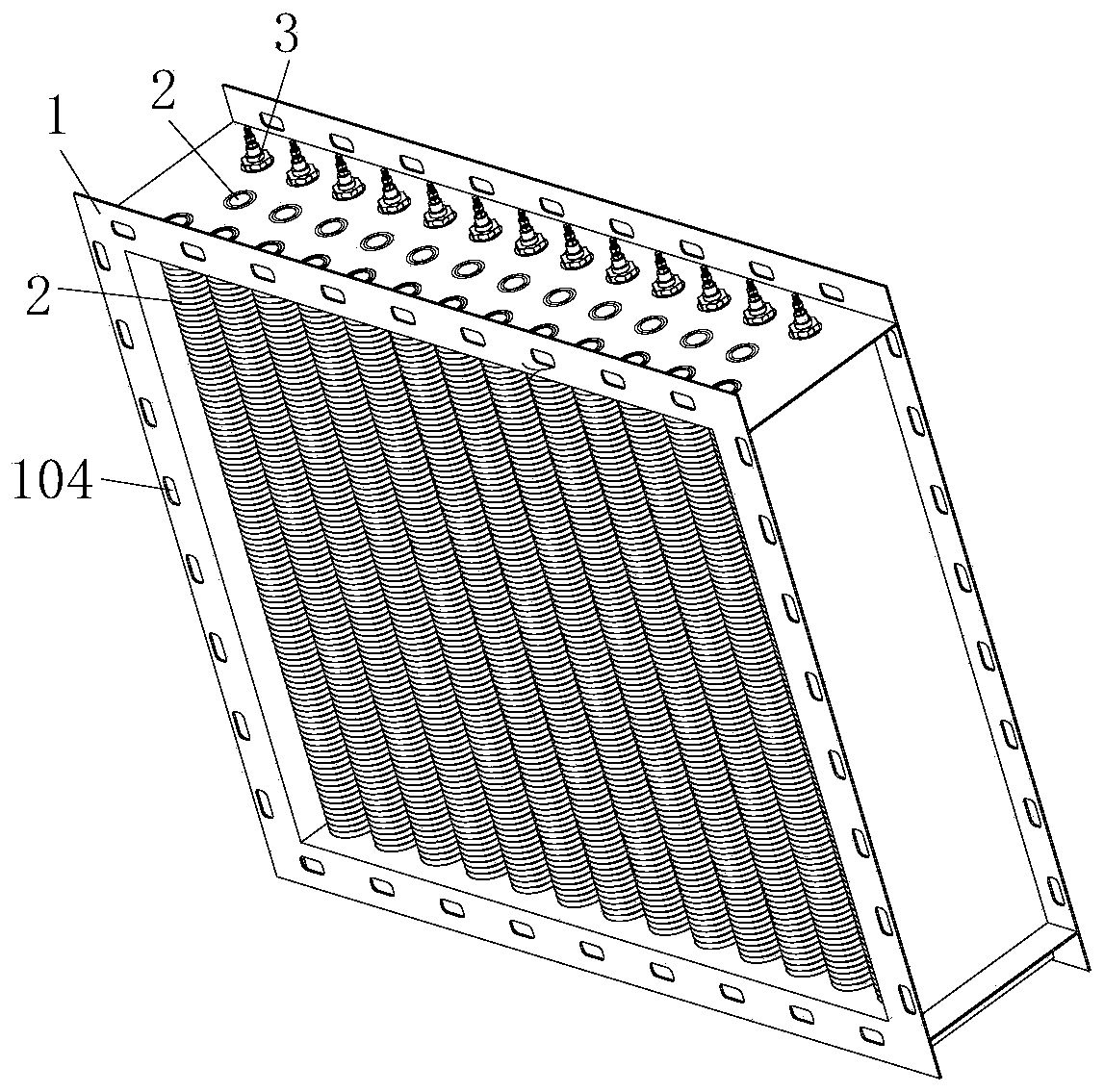

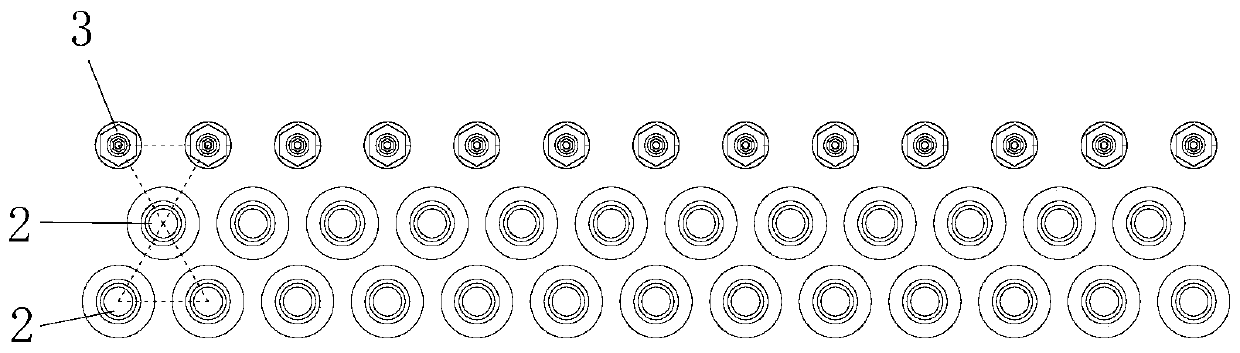

[0029] This embodiment relates to a hot air heat exchanger with constant parameters of molten salt electric auxiliary heating, which mainly includes inlet and outlet chambers respectively constructed on the bottom and top of the frame body, and inlets and outlets are respectively formed on the inlet and outlet chambers, And the inlet is connected with the external molten salt supply device; multiple rows of finned tubes are embedded and fixed in the main body of the frame, and the two ends of each finned tube are respectively connected with the inlet cavity and the outlet cavity, and two adjacent rows of finned tubes staggered between.

[0030] The electric heating tubes of this embodim...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap