Asphalt material dynamic shear modulus low temperature test method

A technology of shear modulus and asphalt materials, which is applied in the field of road material scientific experiments, can solve the problems of large error in test results, difficulty in unifying the size, and inability to apply small-sized samples, etc., to achieve the effect of ensuring accuracy

Inactive Publication Date: 2019-09-03

CHONGQING JIAOTONG UNIVERSITY

View PDF9 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Although the improved dynamic shear rheometer (DSR) can accurately measure the rheological properties of asphalt binder under low temperature conditions, and partially replace the beam bending test (BBR), the improved dynamic shear rheometer (DSR ), there are still the following deficiencies: in the existing technology, the specifications that can be tested for larger-sized asphalt material sample

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Softening point | aaaaa | aaaaa |

Login to View More

Abstract

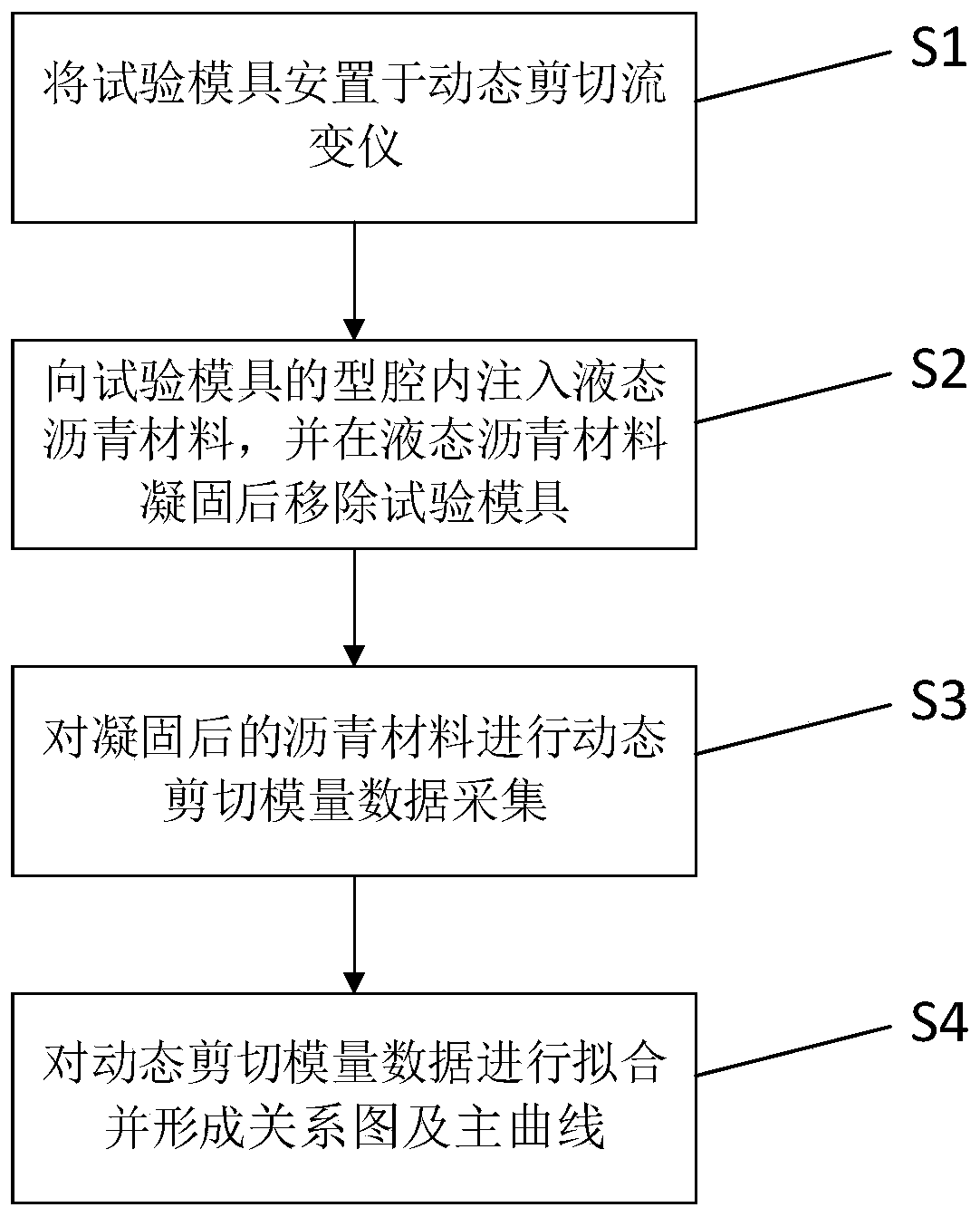

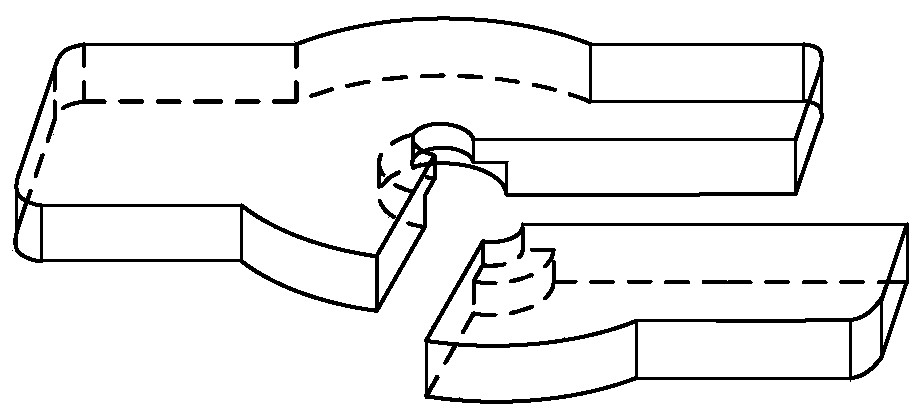

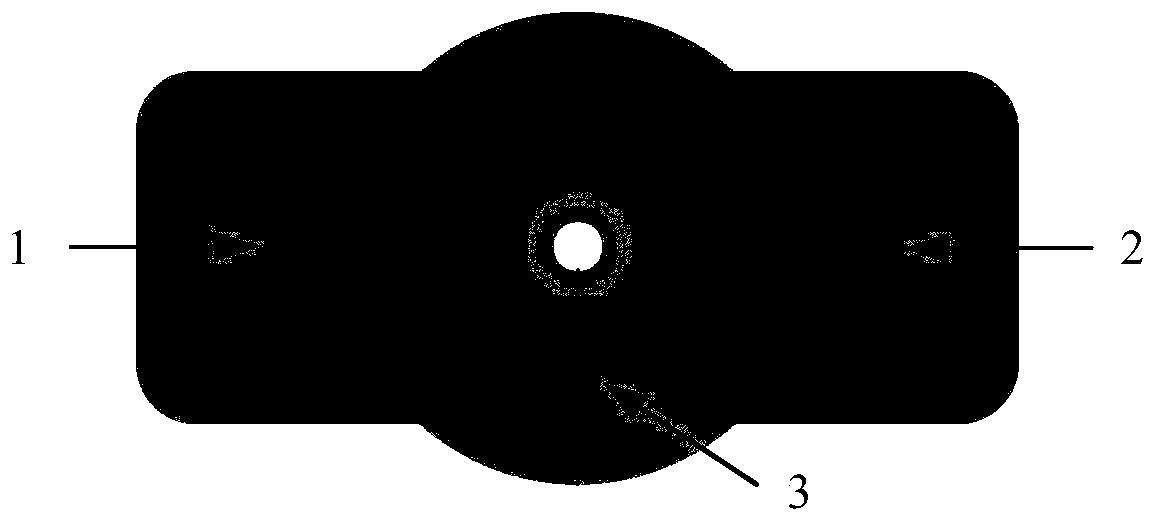

The present invention discloses an asphalt material dynamic shear modulus low temperature test method, comprising following steps: a test mold is placed on a dynamic shear rheometer; S2. a liquid asphalt material is injected into a cavity of the test mold, and the test mold is removed after the liquid asphalt material solidifies; S3. dynamic shear modulus data is collected from the solidified asphalt material, and the dynamic shear modulus data includes a complex shear modulus, a phase angle, a storage shear modulus, and a loss shear modulus; S4. the dynamic shear modulus data is fitted to form a relational graph between the complex shear modulus and the phase angle, a relational graph between the storage shear modulus and the loss shear modulus, a complex shear modulus main curve, and a phase angle main curve. The asphalt material dynamic shear modulus low temperature test method can set a larger sample height to better measure rheological properties of different kinds of asphaltene materials under low temperature conditions while standardizing a sample preparation process.

Description

technical field [0001] The invention relates to the field of scientific experiments on road materials, in particular to a low-temperature test method for dynamic shear modulus of asphalt materials. Background technique [0002] Asphalt binder is one of the important factors affecting the performance of asphalt pavement, so accurate and comprehensive test results of asphalt binder performance are an important basis for the design and construction of asphalt pavement. In the current domestic and foreign standards, the evaluation of asphalt binder generally starts from three levels of high-temperature anti-rutting, medium-temperature anti-fatigue and low-temperature crack resistance, and is equipped with corresponding test instruments, calculation methods and evaluation indicators. At present, the two widely used test instruments are dynamic shear rheometer (DSR) and trabecular bending test (BBR), which can respectively measure the high temperature, medium and low temperature p...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G01N33/42G01N1/44

CPCG01N1/44G01N33/42

Inventor 王威娜秦煜徐长春涂文才陈宇陈斌雷敏赵品毅

Owner CHONGQING JIAOTONG UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com