Optical unit and method for manufacturing the same

A technology for optical units and manufacturing methods, applied to optical components, optics, instruments, etc., which can solve problems such as rising costs of fixed units

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach 〕

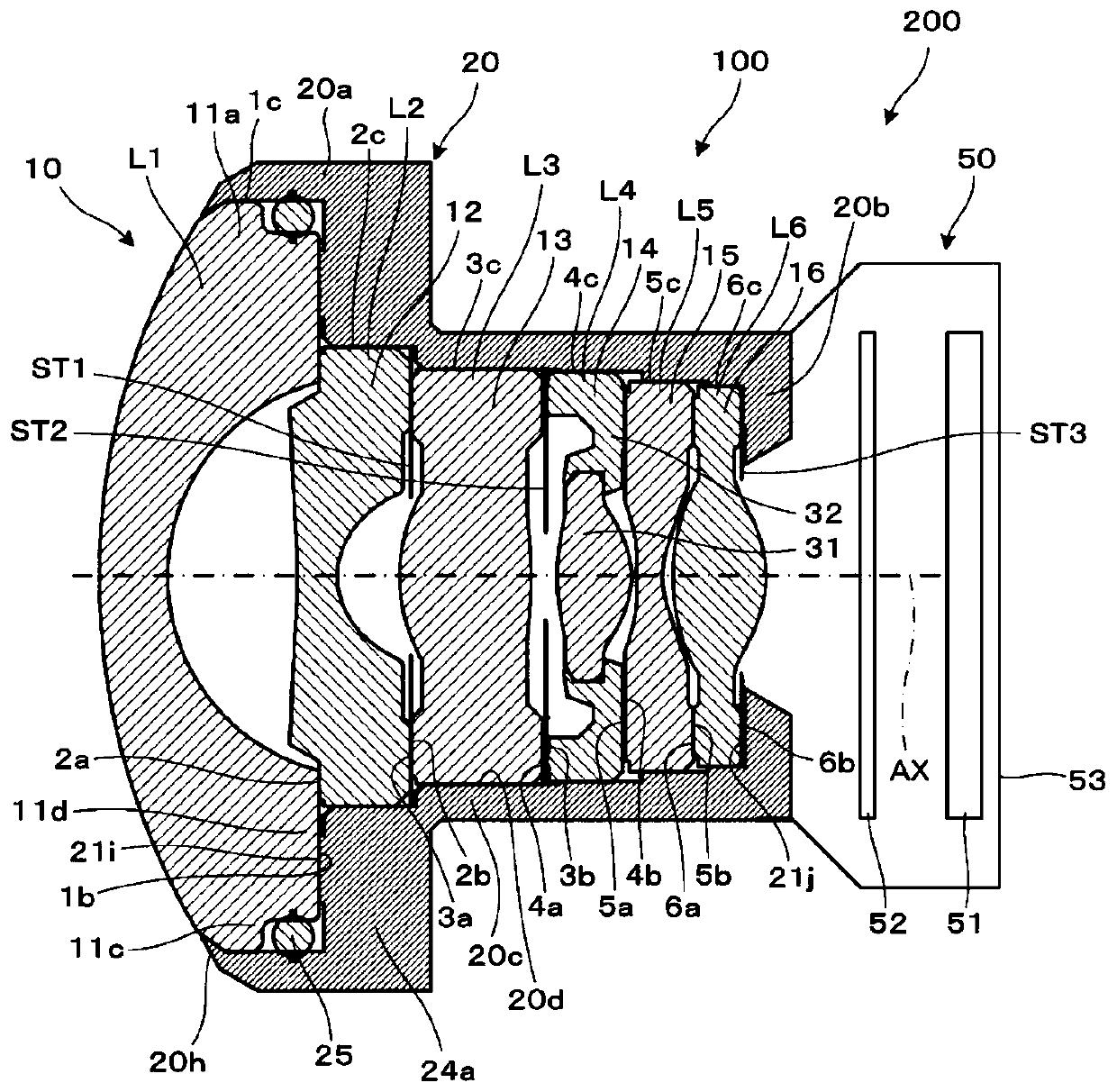

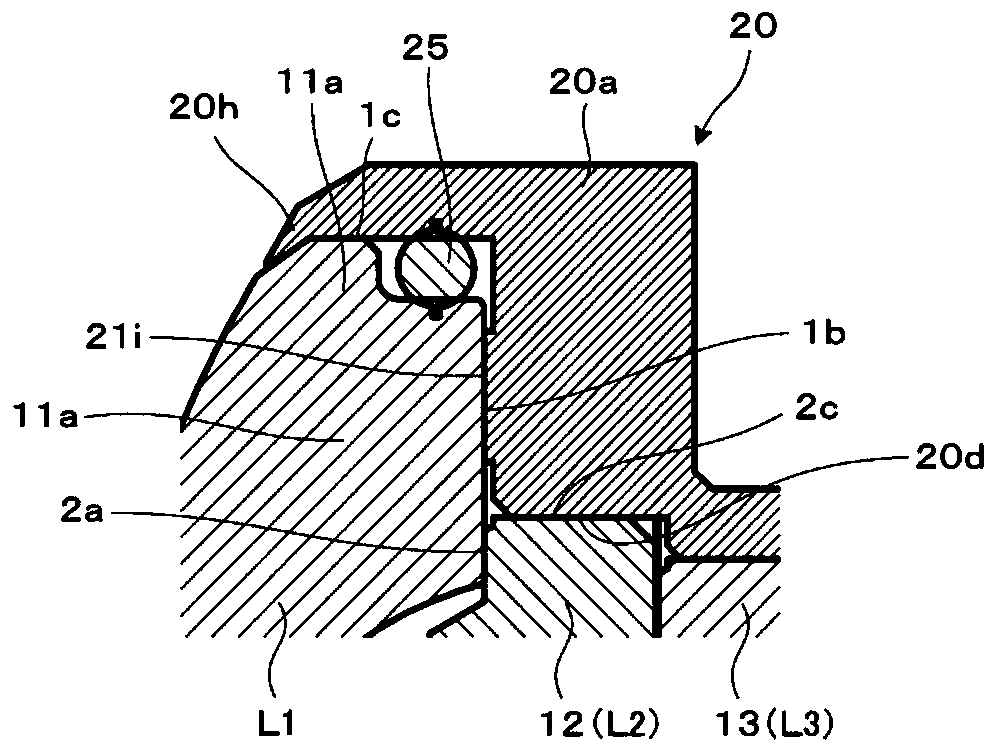

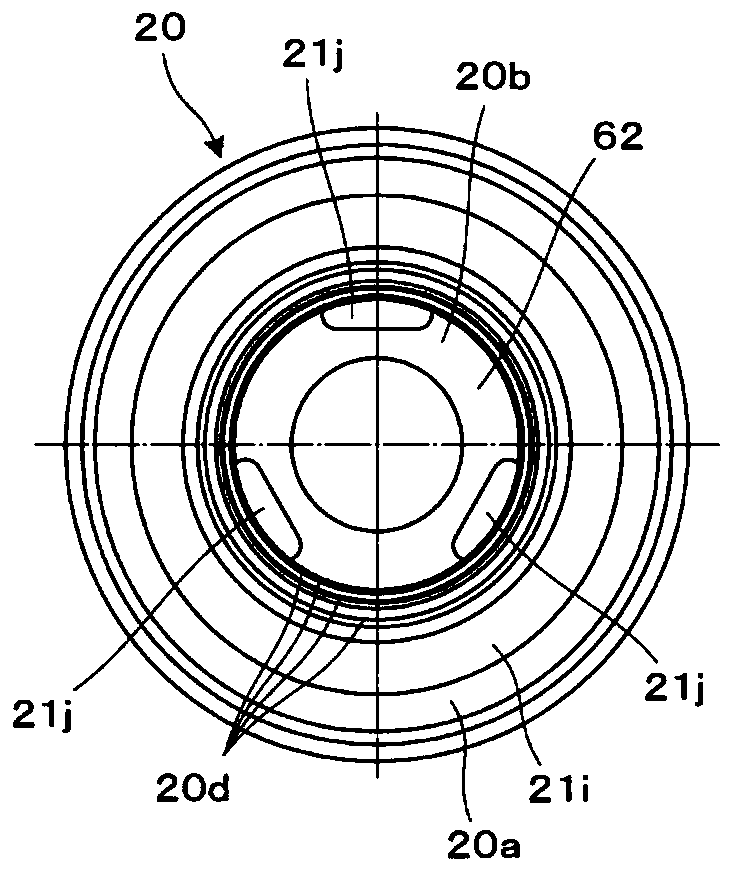

[0024] Hereinafter, an optical unit and an imaging device including the optical unit according to a first embodiment of the present invention will be described with reference to the drawings.

[0025] Such as Figure 1A As shown, the optical unit 100 is combined with the sensor unit 50 to constitute the imaging device 200 . The optical unit 100 includes an imaging optical system 10 and a lens holder 20 that accommodates the imaging optical system 10 . The photographing optical system 10 is composed of first to sixth lenses L1 to L6. Among the first to sixth lenses L1 to L6, the first to third lenses L1 to L3 and the fifth and sixth lenses L5 and L6 are optical lenses made of resin, and the fourth lens L4 has a lens body 31 made of glass, and This lens main body 31 is attached to the optical lens of the resin-made lens frame 32 inside. A stop ST1 is interposed between the second lens L2 and the third lens L3, a stop ST2 is interposed between the lens frame 32 of the third len...

no. 2 approach 〕

[0038] Hereinafter, the optical unit according to the second embodiment will be described. In addition, the optical unit of the second embodiment is obtained by modifying the optical unit of the first embodiment, and matters not particularly described are the same as those of the first embodiment and the like.

[0039] Such as Figure 4A As shown, the optical unit 100 includes an imaging optical system 10 and a lens holder 20 that accommodates the imaging optical system 10 . The imaging optical system 10 is composed of first to sixth lenses L1 to L6, and includes stops ST1 to ST3 as other optical components.

[0040] In this case, the stop ST2 is a resin sheet member functioning as the second member, and has a thickness of about several 10 μm. The stop ST2 is not limited to a stop for adjusting the opening, and may be used for light beam limitation or for ghost countermeasures. The stop ST2 has an abutment surface 8 a perpendicular to the optical axis AX on the third lens L...

no. 3 approach 〕

[0044] Hereinafter, an optical unit according to a third embodiment will be described. In addition, the optical unit of the third embodiment is obtained by modifying the optical unit of the first embodiment, and matters not particularly described are the same as those of the first embodiment and the like.

[0045] Such as Figure 5A As shown, the optical unit 100 includes an imaging optical system 10 and a lens holder 20 that accommodates the imaging optical system 10 . The imaging optical system 10 is composed of first to sixth lenses L1 to L6, and includes stops ST1 to ST3 as other optical components.

[0046] In this case, only the first lens L1 is independently fixed to the lens holder 20 , and the second to sixth lenses L2 to L6 are supported on the lens holder 20 in a stacked state. In other words, the second to sixth lenses L2 to L6 are held in the lens holder 20 in a fitted state, positioned in a direction perpendicular to the optical axis AX, and movable or slidable...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com