A method and system for heat dissipation temperature control of a transformer

A technology for transformers and temperature regulation, applied in the field of transformers, can solve the problems of reducing the temperature control and voltage control performance of the transformer, insufficient temperature control sensitivity of the transformer, and low operating efficiency of the transformer, so as to reduce the risk of overload and overheating, and improve the rapid regulation. ability, reducing the effect of frequent adjustments

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with specific embodiment:

[0011] A method for heat dissipation temperature control of a transformer, comprising the following steps:

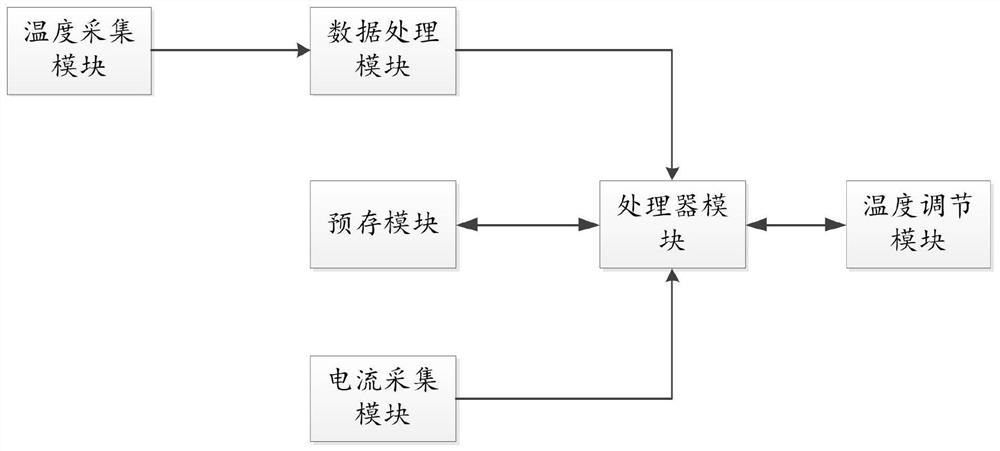

[0012] The temperature acquisition module collects the temperature signal in the transformer and the transformer cabinet, and transmits the temperature signal to the data processing module for processing;

[0013] The data processing module processes the temperature signal and transmits it to the processor module. The processor module compares the temperature signal obtained at this moment with the temperature threshold stored in the pre-stored module. When the temperature exceeds the threshold, it outputs a control signal instruction to the temperature regulator. module;

[0014] The temperature regulation module regulates the temperature in the transformer cabinet according to the regulation signal instruction.

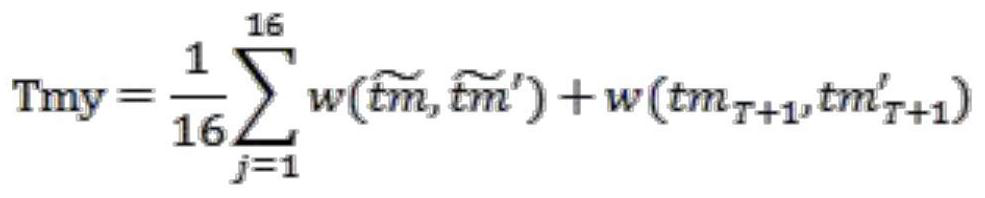

[0015] When the processor module compares the tempe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com