Lithium battery packaging pressing fixture

A technology for pressing jigs and lithium batteries, which is used in secondary battery manufacturing, battery pack components, battery boxes/jackets, etc. Problems, to ensure the processing environment and processing quality, the effect of novel design structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

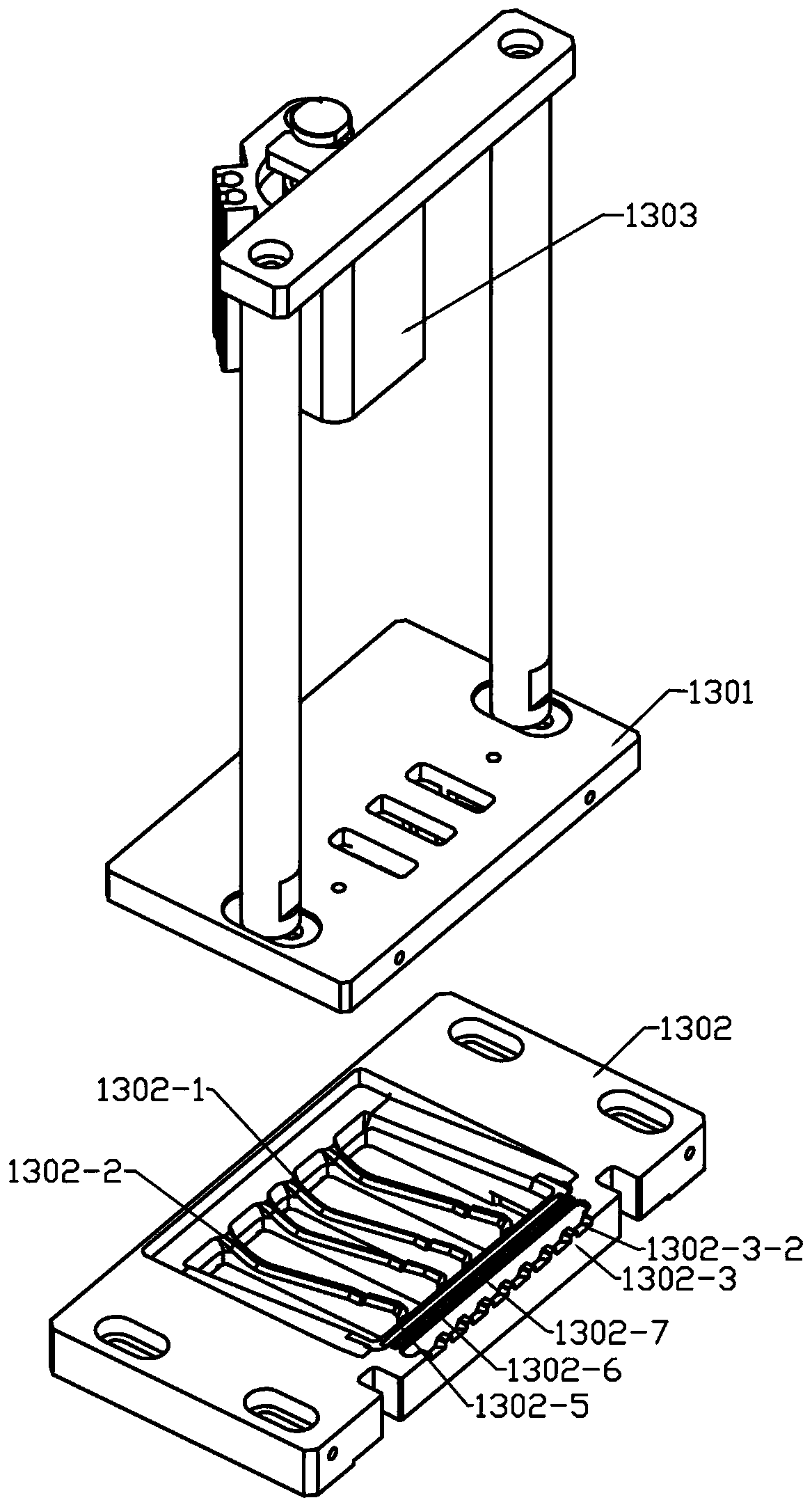

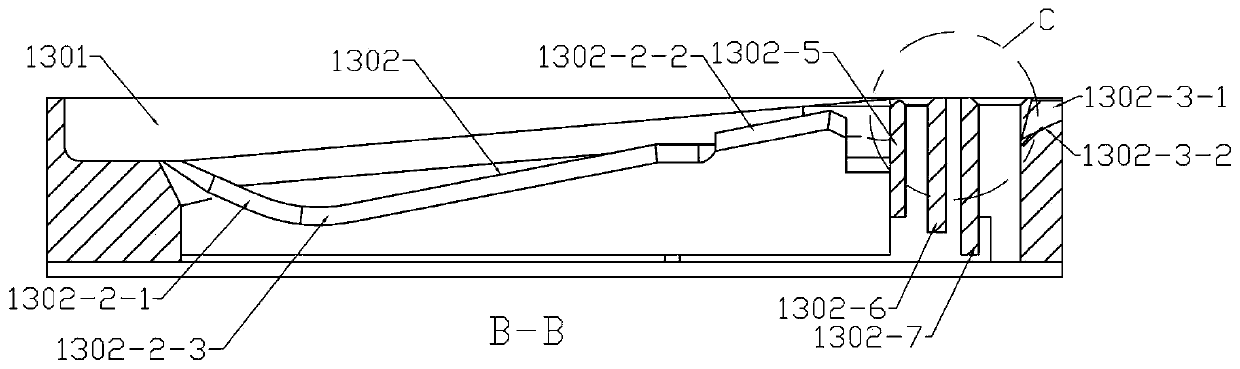

[0021] Specific Example 1: See Figure 1 to Figure 8 , in an embodiment of the present invention, a lithium battery packaging and bonding fixture includes an upper pressing plate 1301, an upper pressing plate driving device 1303 and a lower pressing plate 1302, the upper pressing plate 1301 is connected to the upper pressing plate driving device 1303 by driving, and the upper pressing plate The driving device 1303 drives the upper pressing plate 1301 to move up and down, and the upper pressing plate driving device 1303 is driven by an air cylinder.

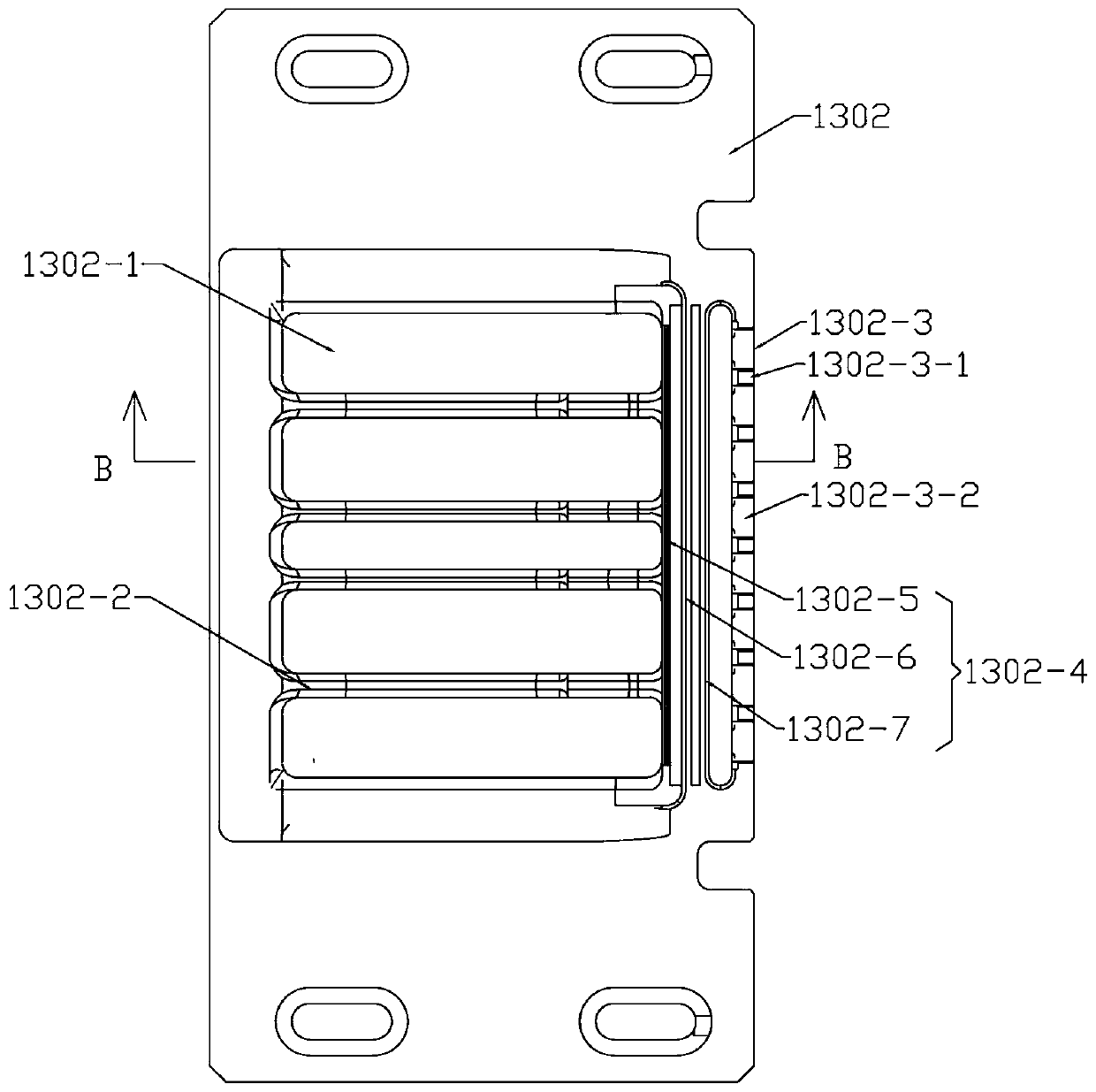

[0022] In the middle of the lower platen 1302 is an accommodating area 1302-1 with an inwardly recessed hollow structure. In the accommodating area 1302-1, there are several supporting bars 1302-2 with the same structure, and the supporting bars 1302-2 are arranged side by side. Set in the accommodating area 1302-1, the support bar 1302-2 includes a left support part 1302-2-1 and a right support part 1302-2-2, and the left support...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com