Horizontal butt joint placement device

A kind of equipment and level technology, applied in the direction of lifting device, lifting frame, etc., can solve the problems of insufficient compact structure, equipment can not meet the requirements, operation is difficult, etc., to increase the operation stability, good self-locking, reduce operating force. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The technical solution of the present invention is further described below, but the scope of protection is not limited to the description.

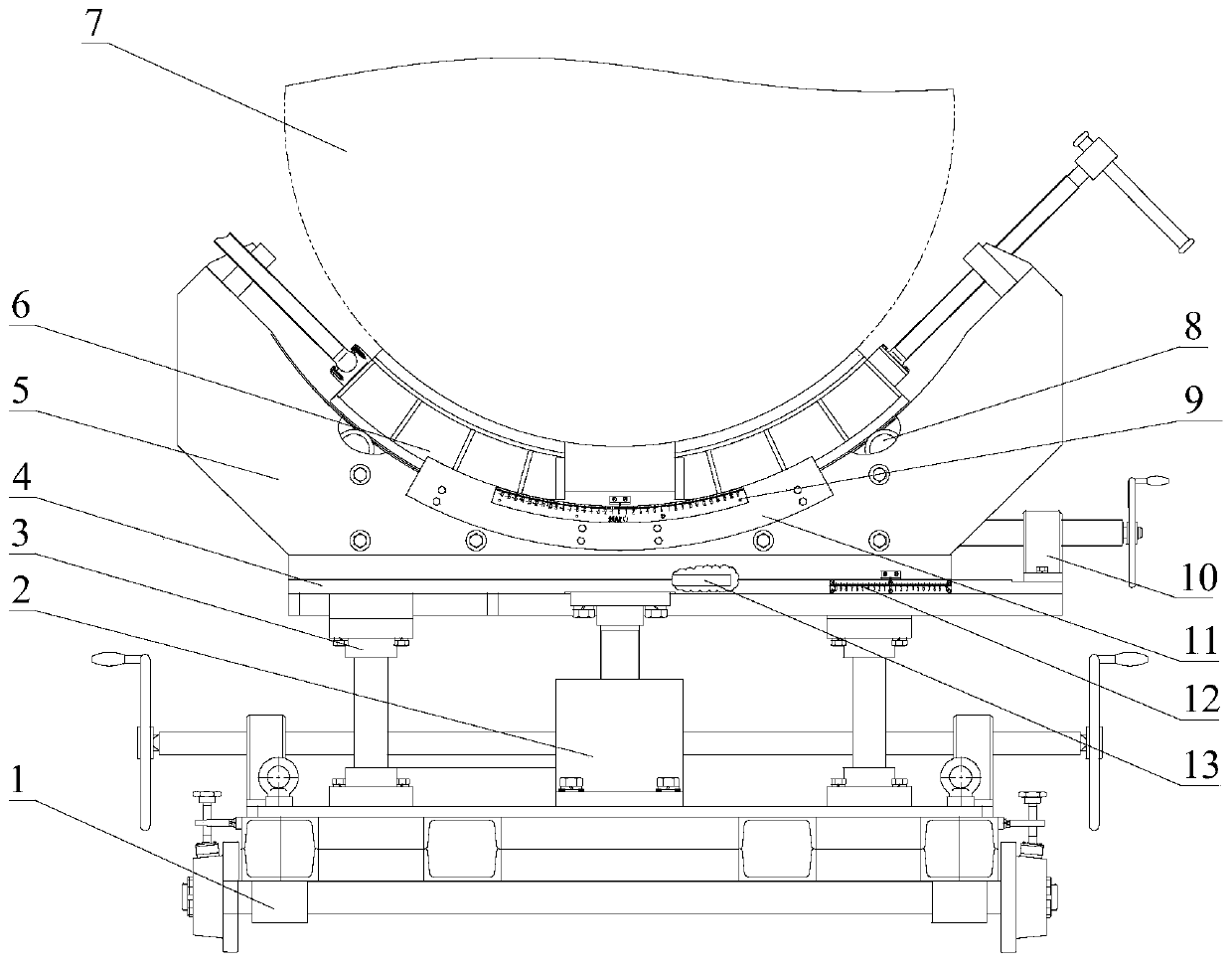

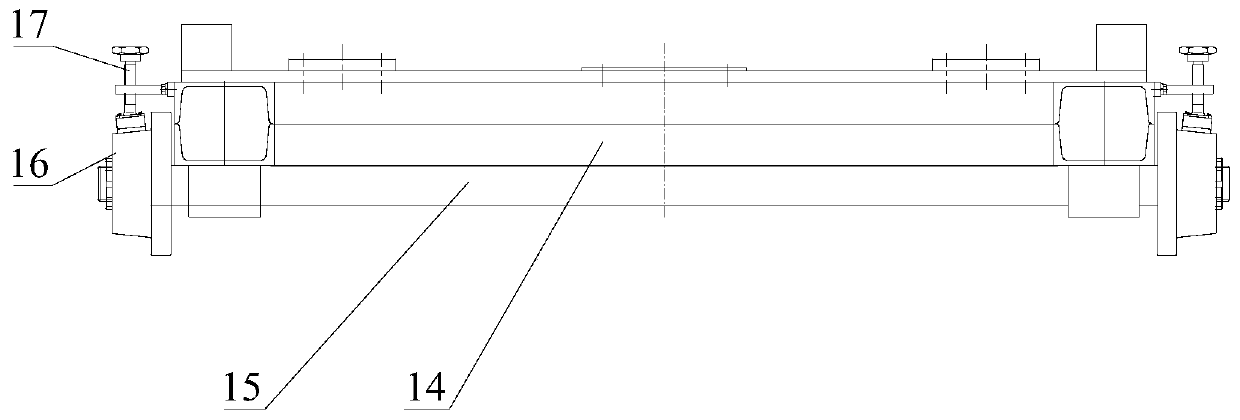

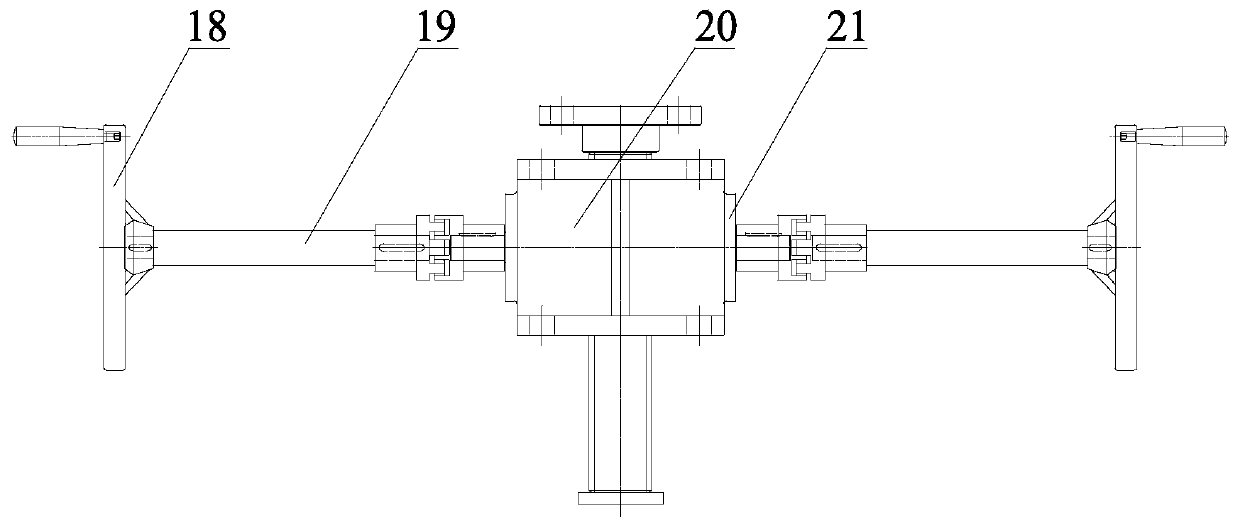

[0024] Such as Figure 1 to Figure 6 A horizontally docked parking device shown includes a traveling device 1, a mounting seat 4, and an elevator 2; the elevator 2 is fixed on the traveling device 1, and the mounting seat 4 is fixed on the top of the elevator 2; between the traveling device 1 and the mounting seat 4 A guide post guide sleeve 3 is fixed between them, and the guide post guide sleeve 3 guides the lifting of the installation seat 4; a linear guide rail 13 is arranged on the installation seat 4, and a rolling drive mechanism 5 is mounted on the linear guide rail 13 and is moved laterally The mechanism 10 controls the lateral movement; the rolling drive mechanism 5 is equipped with a rolling bracket 6 for installing and debugging the product 7 .

[0025] A rolling shaft 8 is installed on the rolling driving mechanism 5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com