Bottom section adding hydraulic jacking system and construction method

A construction method and technology of hydraulic jacks, which are applied in construction, building structure and other directions, can solve the problems of reduced construction efficiency, reduced anti-overturning stability, reduced stability of the jacking system, etc., and achieves rapid installation and improved anti-overturning stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

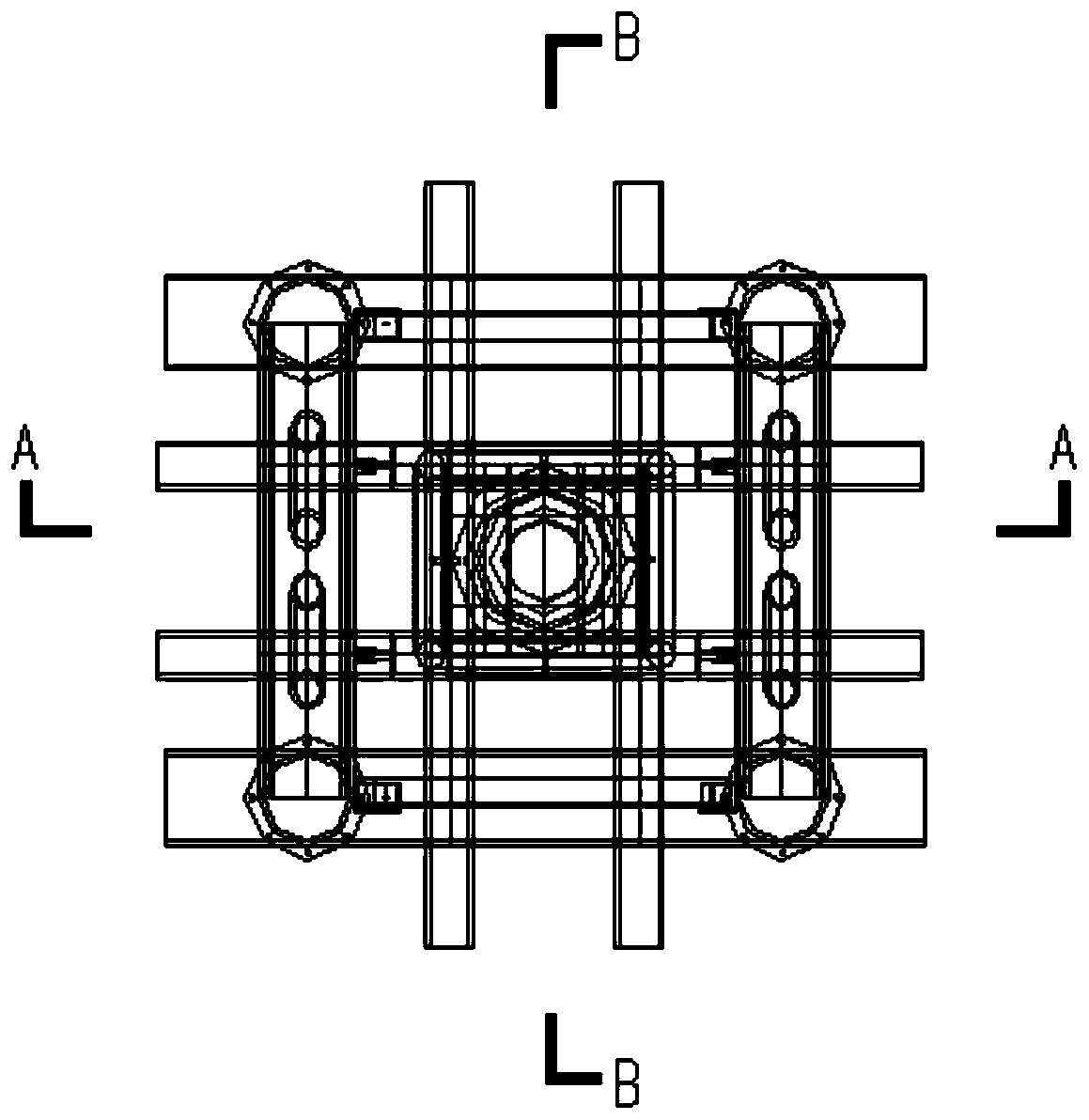

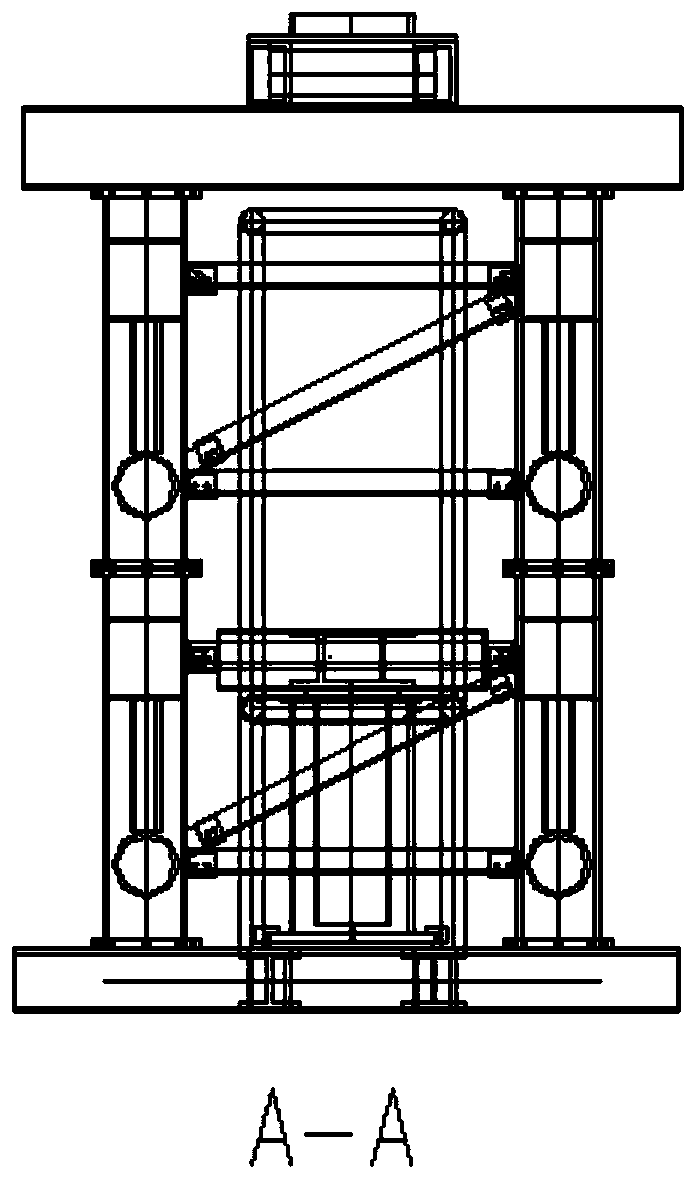

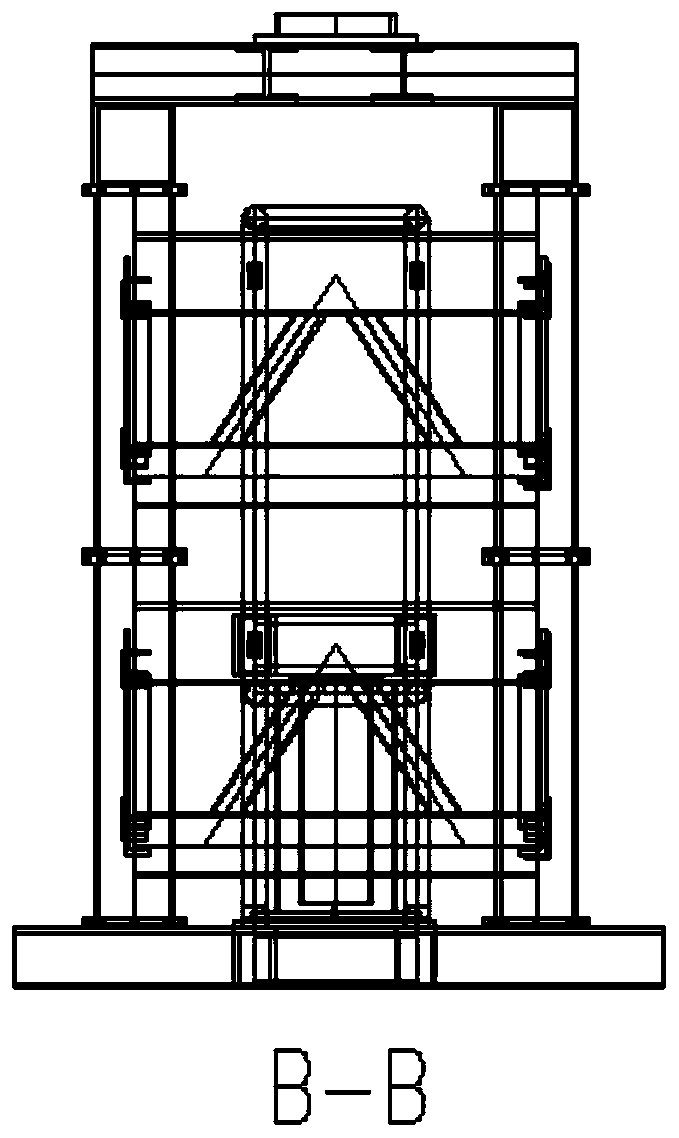

[0024] The following will be combined with Figure 4 , 5 And embodiment, the present invention is described in further detail.

[0025] In the embodiment of the present invention, the jacking system consists of jacking reaction frames (1, 2, 5), anti-overturning stabilizers (3), jacking frame standard sections (4, 6) and top supporting well-tac-toe platforms (9, 10, 11) composition. The jacking reaction frame is composed of the bottom well-shaped beam 1, the hydraulic jack 2 and the jacking beam 5; the anti-overturning stable frame 3 is composed of a vertical rod A and two horizontal connecting rods B in the height direction, and the rods are all made of circular tube sections; The standard section (4, 6) of the jacking frame adopts a rectangular section form, and is formed by connecting several standard sections with flanges 8 . The standard section is composed of two finished plane trusses 6 and the connecting angle steel 4 between the trusses. The angle steel and the fin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com