Portal type double-row pile system of rear row pile anchor and construction method of portal type double-row pile system

A construction method and technology for rear row piles, which are applied in excavation, sheet pile wall, foundation structure engineering, etc., can solve problems such as increase in engineering cost, and achieve the effect of controlling engineering cost, facilitating temporary emergency reinforcement, and reducing engineering cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

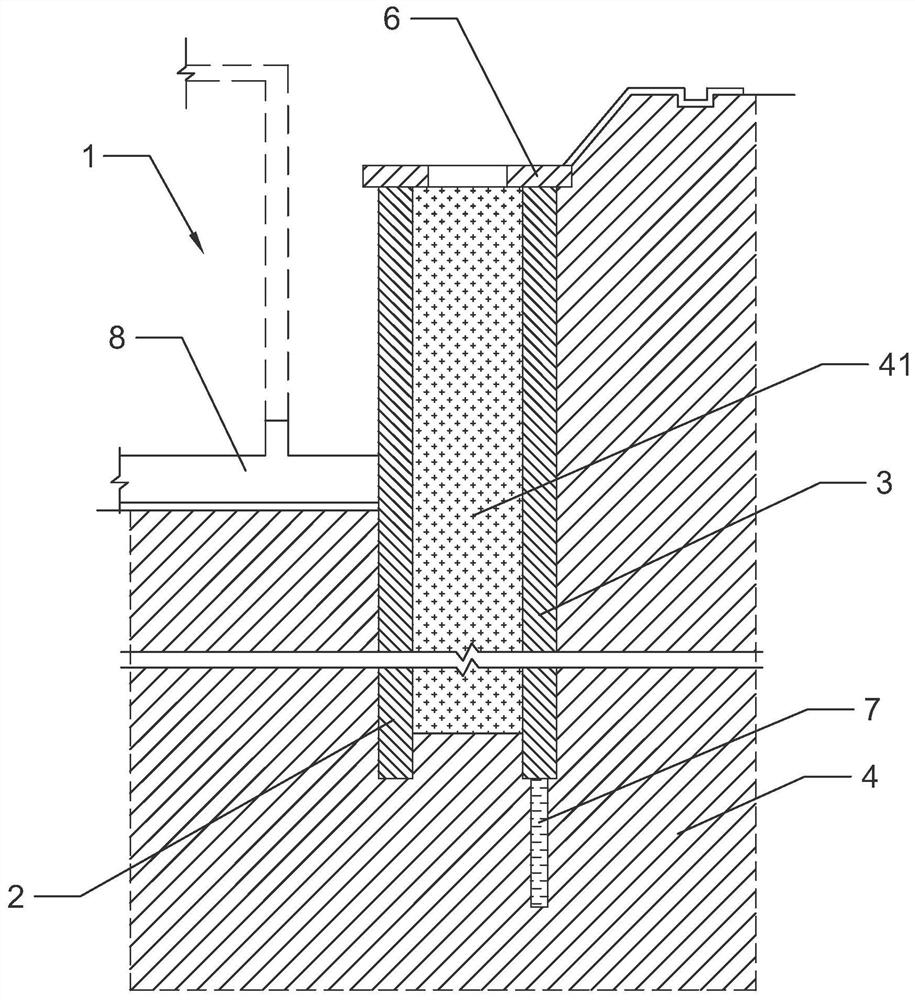

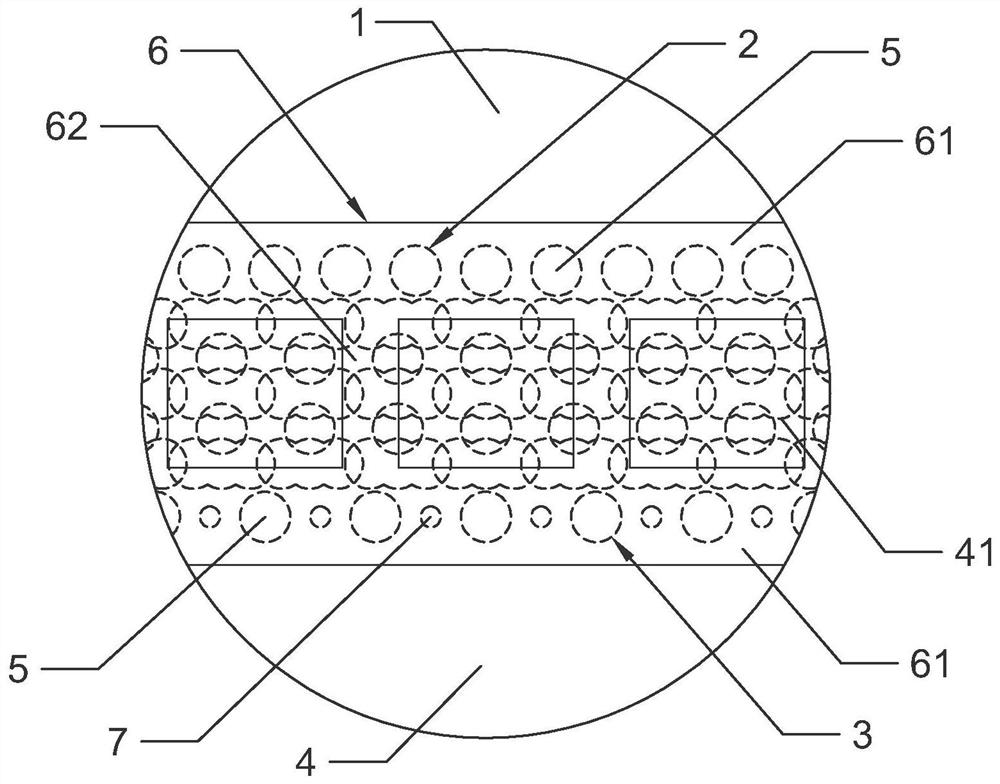

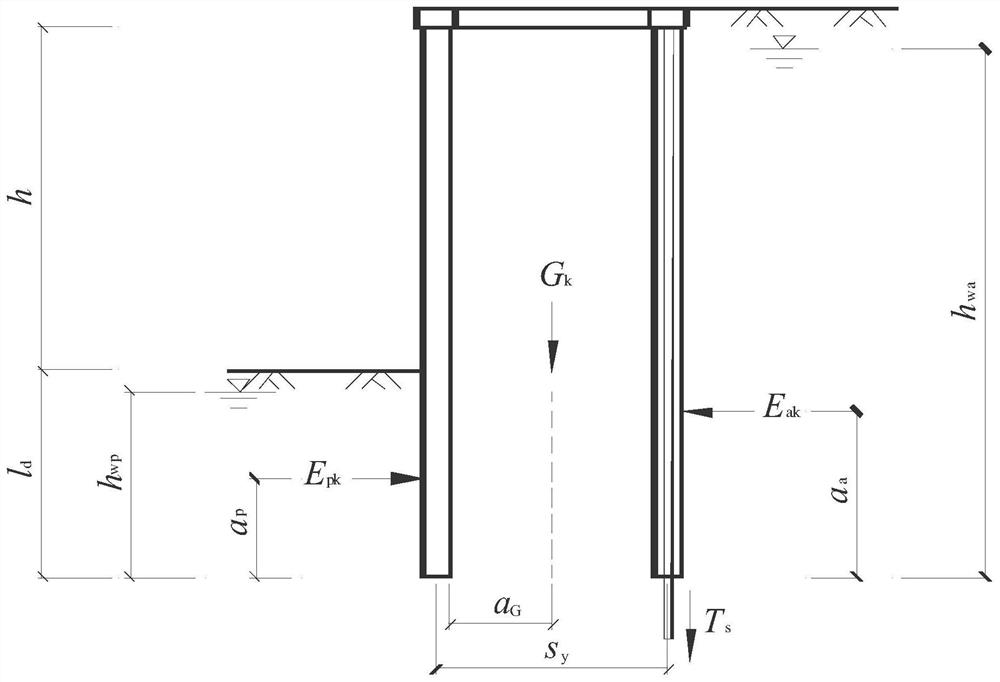

[0024]SeeFigure 1 - Figure 3 , The rear pose double-row pile system of the rear pose anchor includes the front row pile 2 and the rear pile 3, and the front row pile 2 is disposed on the inner side surface of the pit body 1 in the pit body 1. Inside, the outer surface of the rear pose 3 wind body 1 is provided in the soil layer 4, and the front row pile 2 and the rear pile 3 are composed of a plurality of equally equally spaced piles 5, located in the front pose 2 and the rear pile. The soil 41 between the 3 is reinforced by a high-pressure spinning pile. The high-pressure spinning pile is reinforced with the soil of soil. The high pressure spun pile is 700mm, the pile spacing is 500mm, the bit is 200mm, high pressure rotation The cement dosage of the spray pile is 20%, and between the front row pile 2 and the rear pile 3 are connected by the rigid frame 6, the anchor cable 7 is arranged between the two piles 5 adjacent in the rear pile 3, the The spacing between the front row pile ...

Embodiment 2

[0042]SeeFigure 4 The basic structure of the door frame type double row pile system and its construction method thereof is substantially the same, and the pile 5 in the rear pile 3 is hollow pile. The anchor cable 7 is disposed in the pile 5 in the rear pile 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com