Self-resetting friction damper

A friction damper and self-resetting technology, which is applied to building types, buildings, building components, etc., can solve the problems of building structure stress and use functions that are difficult to repair, friction damper large displacement, etc., achieve good energy consumption effect, reduce Vibration response, the effect of extending the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

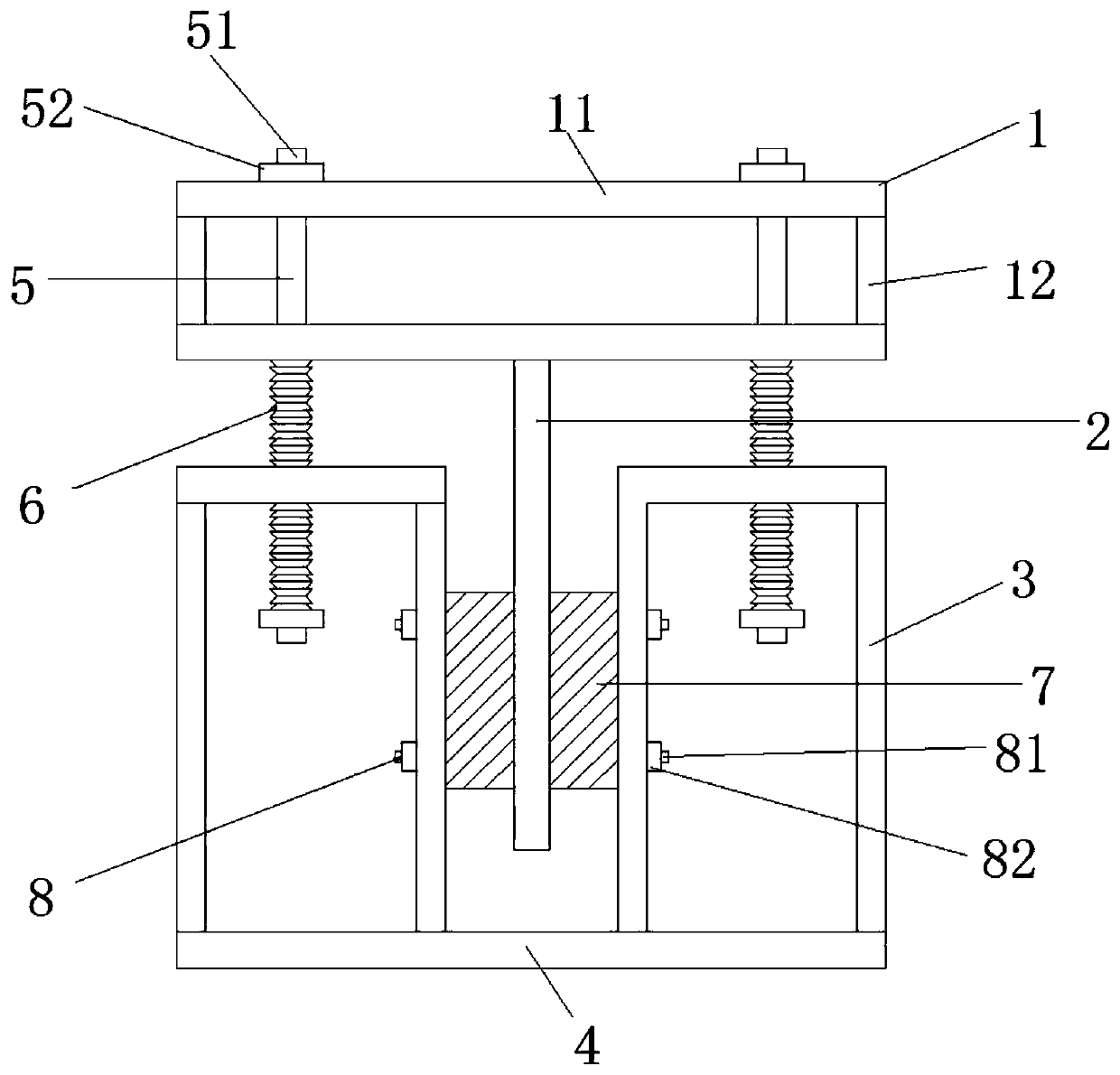

[0068] See attached figure 1 And attached figure 2 , the embodiment of the present invention discloses a self-resetting friction damper, including: a steel plate composite member 1, a piston member 2, a box-shaped member 3, a bottom plate 4, a fastener 5, an elastic member 6 and a friction plate 7;

[0069] The steel plate composite member 1 includes a flange plate 11 and a web 12; two flange plates 11 are arranged in parallel up and down; a plurality of web plates 12 are fixed between the two flange plates 11;

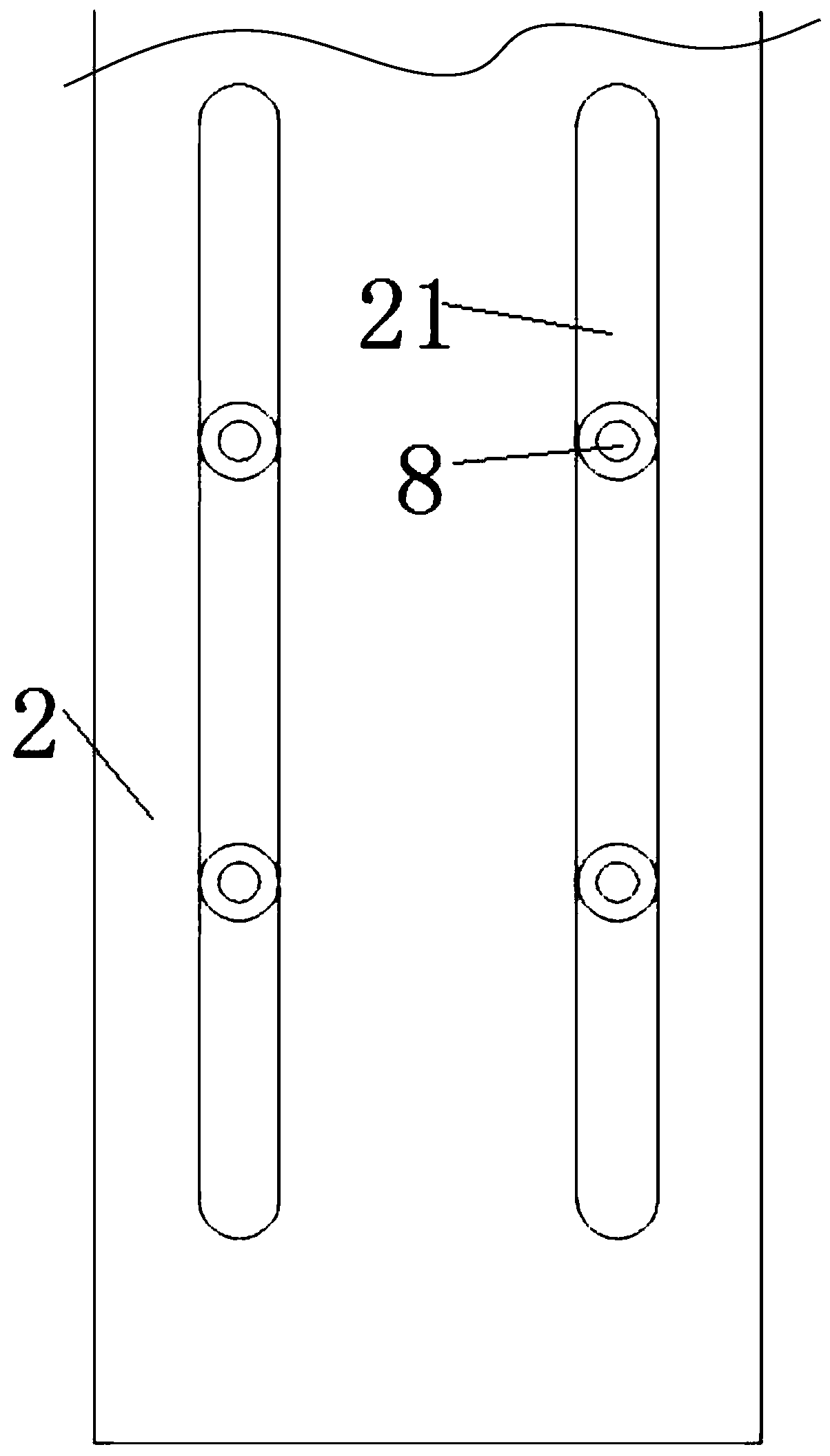

[0070] The piston member 2 is fixedly connected to the center of the bottom surface of the lower flange plate 11;

[0071] The box-shaped member 3 is a box-shaped structure with both ends open or closed, and a plurality of box-shaped members 3 are arranged around the piston member 2;

[0072] The bottom plate 4 is respectively fixedly connected to the bottoms of the multiple box-shaped components 3; the bottom plate 4 serves as the common bottom of the multiple box...

Embodiment 2

[0088] The difference between this embodiment and Embodiment 1 is that there are four fasteners 5, which are respectively fixed at the front, rear, left, and right four corners of the upper flange plate 11 of the steel plate composite member 1.

[0089] Other structures and working principles of this embodiment are the same as those of Embodiment 1, and will not be repeated here.

Embodiment 3

[0091] The difference between this embodiment and Embodiment 1 is that the piston member 2 is a triangular box-shaped structure composed of three steel plates, the number of the box-shaped members 3 and the friction plates 7 are three, and the box-shaped members 3 are respectively located in three On the outer side of the steel plates, the friction plates 7 are respectively located between each steel plate and the box member 3 .

[0092] Other structures and working principles of this embodiment are the same as those of Embodiment 1, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com