A kind of drainage method based on siphon roof drainage structure

A roof drainage structure, siphon type technology, applied in the direction of roof drainage, roof, roof covering, etc., can solve the problems of difficult drainage of accumulated water, roof cracks, poor rainwater suction function, etc., to improve the service life and structural strength , Reduce the occurrence of roof cracks and improve the efficiency of roof drainage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

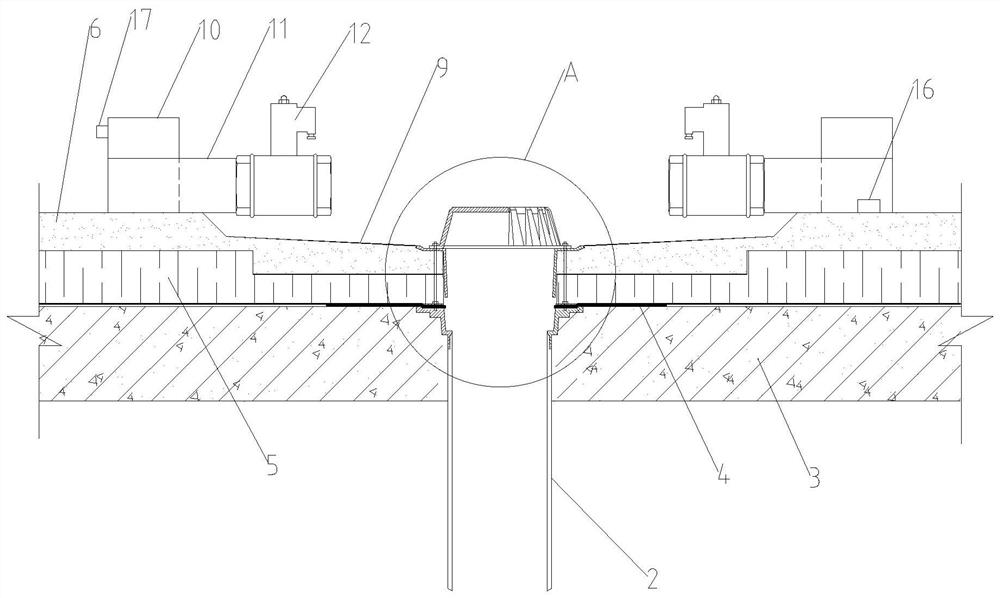

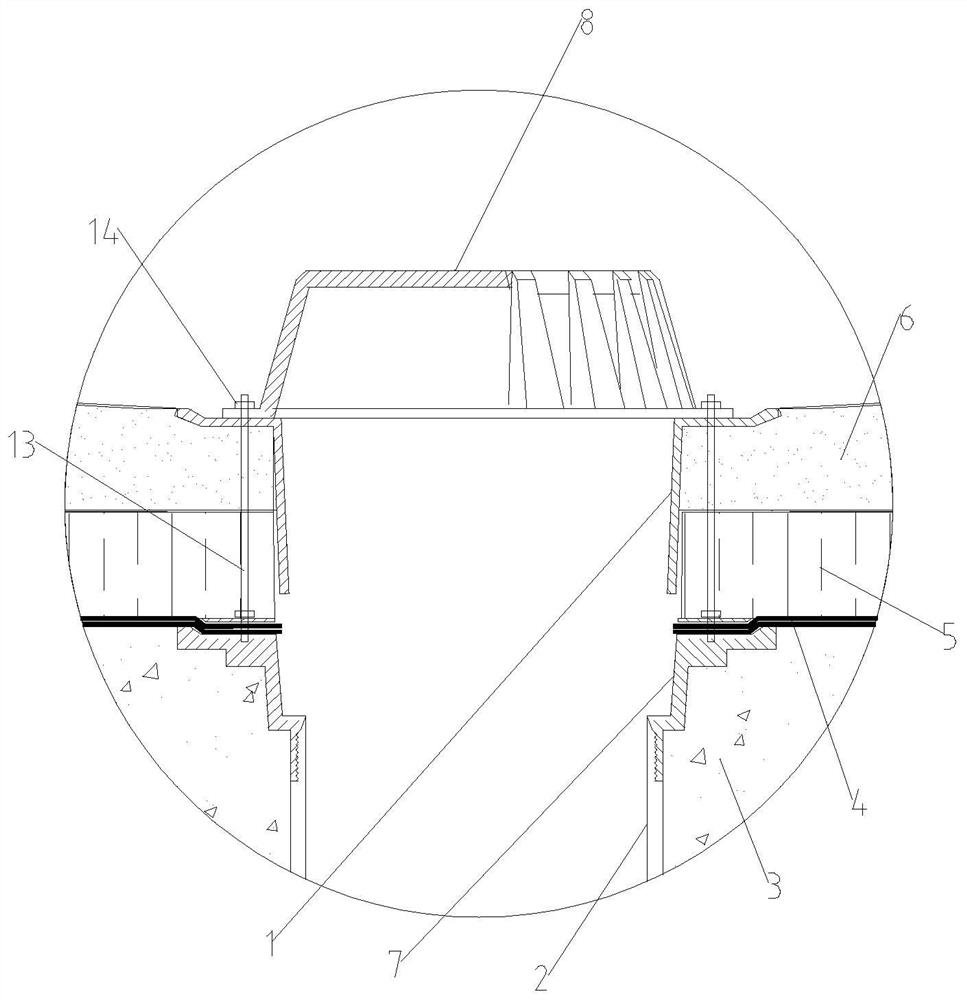

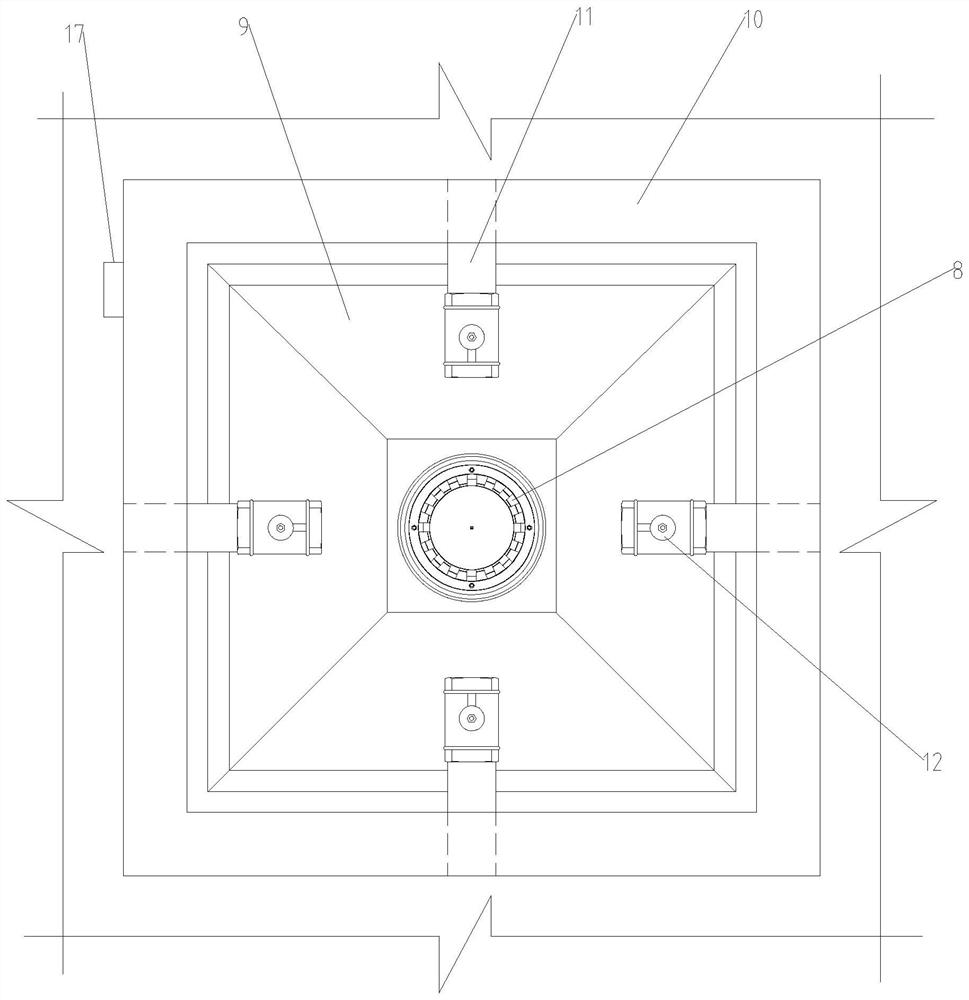

[0054] A drainage method based on a siphonic roof drainage structure, such as figure 1 with figure 2 As shown, the siphon type roof drainage structure includes a downspout 1 and a downpipe 2 installed in the roof, and the roof includes a concrete structure layer 3, a waterproof layer 4, an insulation layer 5 and a concrete surface layer 6 from bottom to top. The concrete surface layer 6 is provided with a sump 9 for the installation of the sink 1, the top of the sump 9 is provided with an annular anti-sill 10, and the annular anti-sill 10 is provided with a plurality of guide pipes 11, so One end of the guide tube 11 is flush with the outer wall of the annular anti-sill 10, the other end of the guide tube 11 extends into the interior of the annular anti-sill 10, and the upper end of the guide tube 11 extends into the interior of the annular anti-sill 10 A solenoid valve 12 is arranged on the section of the trough, and the falling water bucket 1 includes a frustum-shaped cyli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com