Column structure, column and fence system and anti-pull method

A column and fence technology, applied in the direction of fence, road, building type, etc., can solve the problems of reducing the resistance of the column and increasing the cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

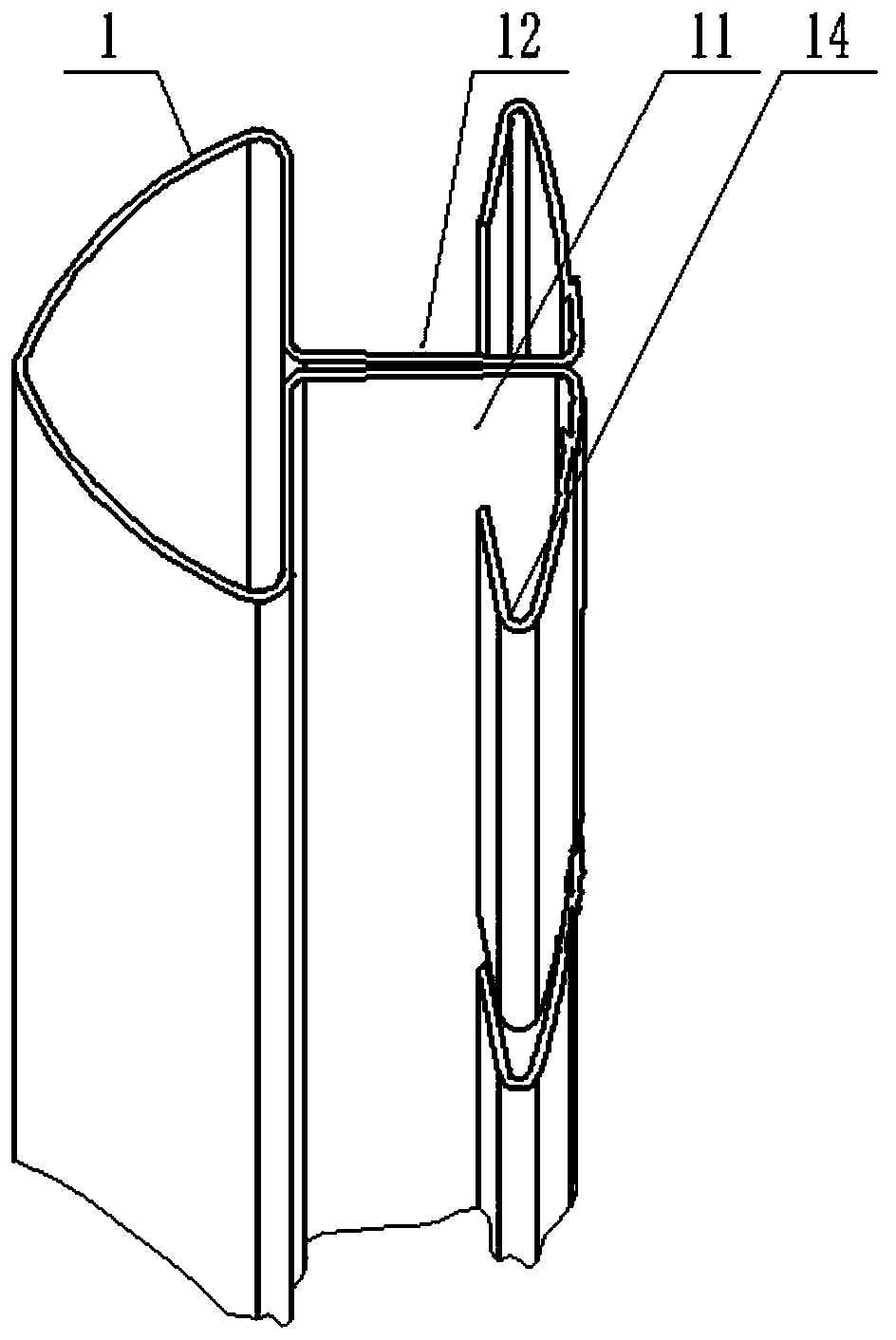

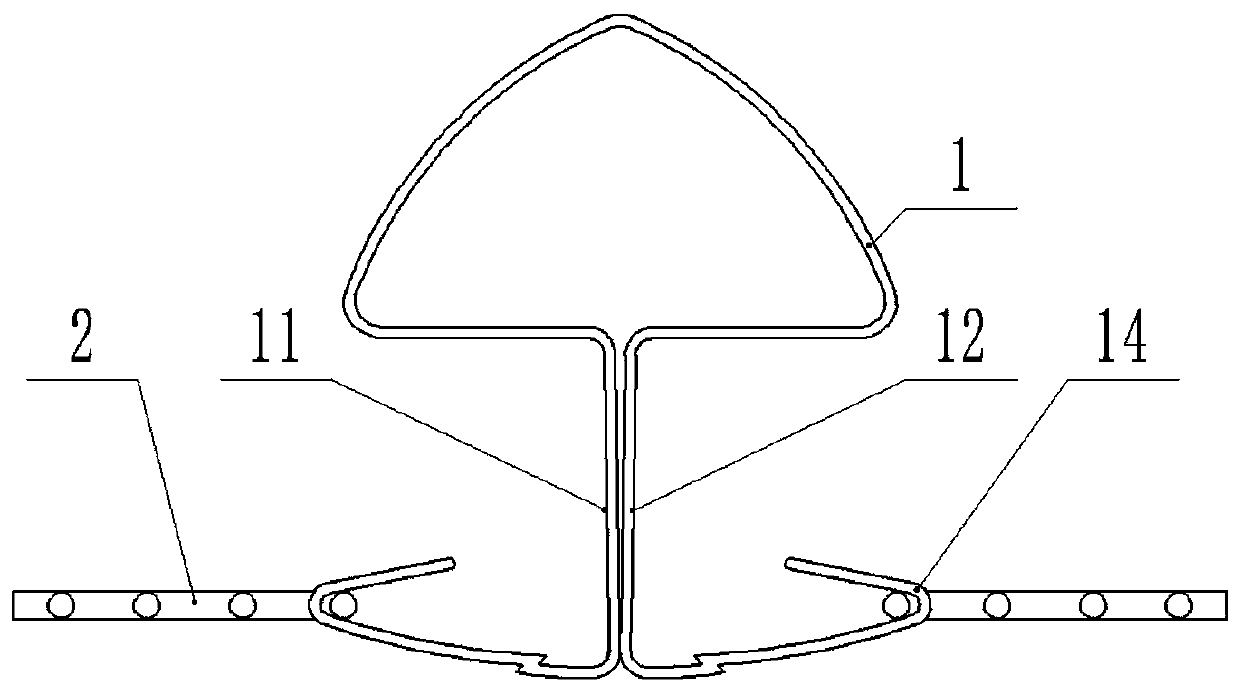

[0046] A column structure, wherein, such as Figure 5 , 6 As shown, the main body 1 is included, and the main body 1 includes: a first base portion 11 , a second base portion 12 , a mounting portion 13 , a supporting portion 15 , and a damping portion 16 .

[0047] Such as Figure 5 As shown, the first base portion 11 is in contact with the second base portion 12 . The mounting portion 13 is formed by bending the right ends of the first base portion 11 and the second base portion 12 to the front and rear sides. The mounting portion 13 includes a hook portion 14. The hook portion 14 is formed by bending the front or rear edge of the mounting portion 13. The hook portion 14 has Opening, the opening faces the direction of the inner mounting part 13, and the hook part 14 extends along the longitudinal direction. The support part 15 is formed by bending the left ends of the first base part 11 and the second base part 12 to the front and rear sides, and the support part 15 is a h...

Embodiment 2

[0068] A column, the column includes the technical solution of any column structure in the first embodiment above.

Embodiment 3

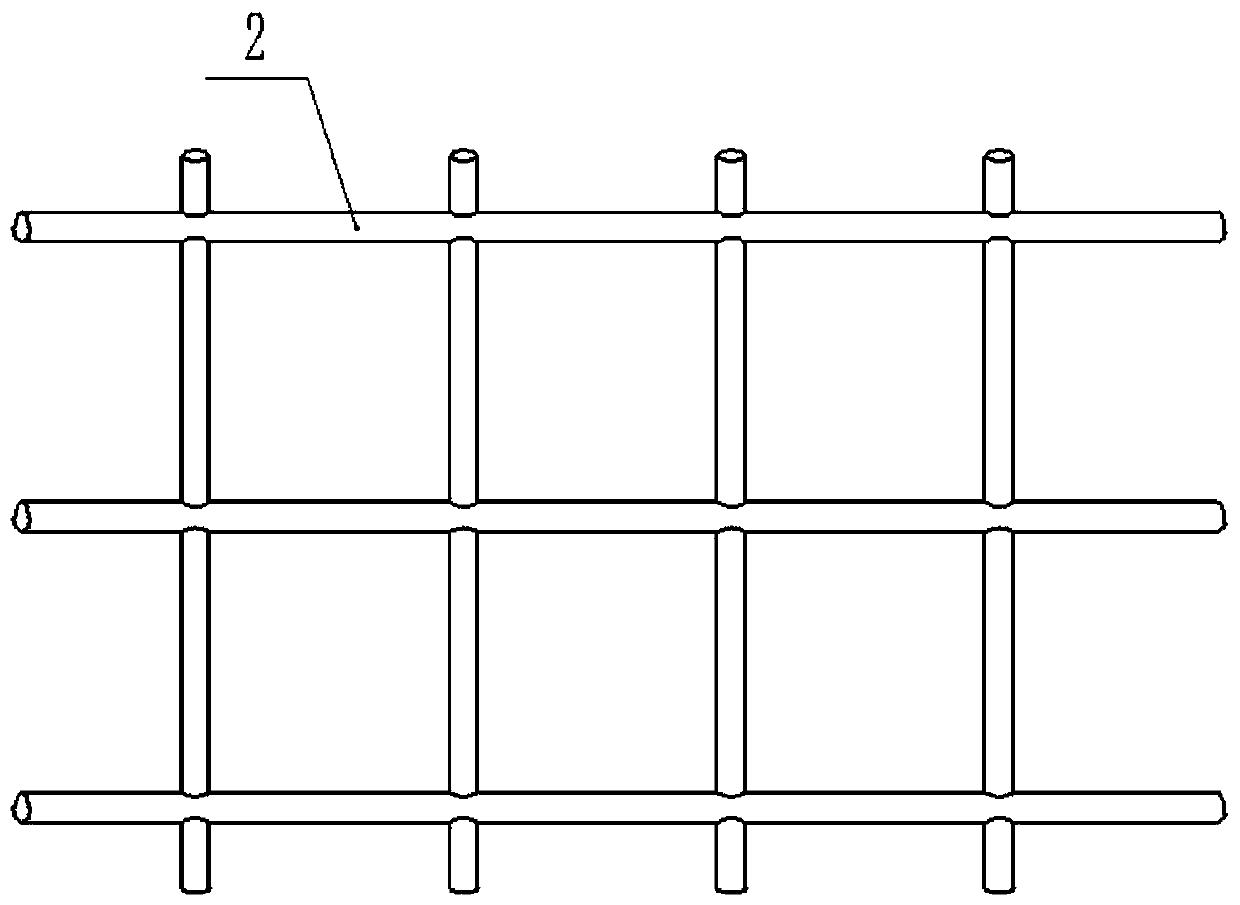

[0070] A fence system, the fence system is composed of a fence post and a mesh 2 installed on the fence post, and the fence system includes the post of the second embodiment above.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com