Oil screen device for extractor range and extractor range

A range hood and oil net technology, which is applied in the direction of oil fume removal, applications, household stoves, etc., can solve the problems of poor user experience, waste of energy, loud noise, etc., and achieve the effect of improving user experience and efficiently sucking oil fume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

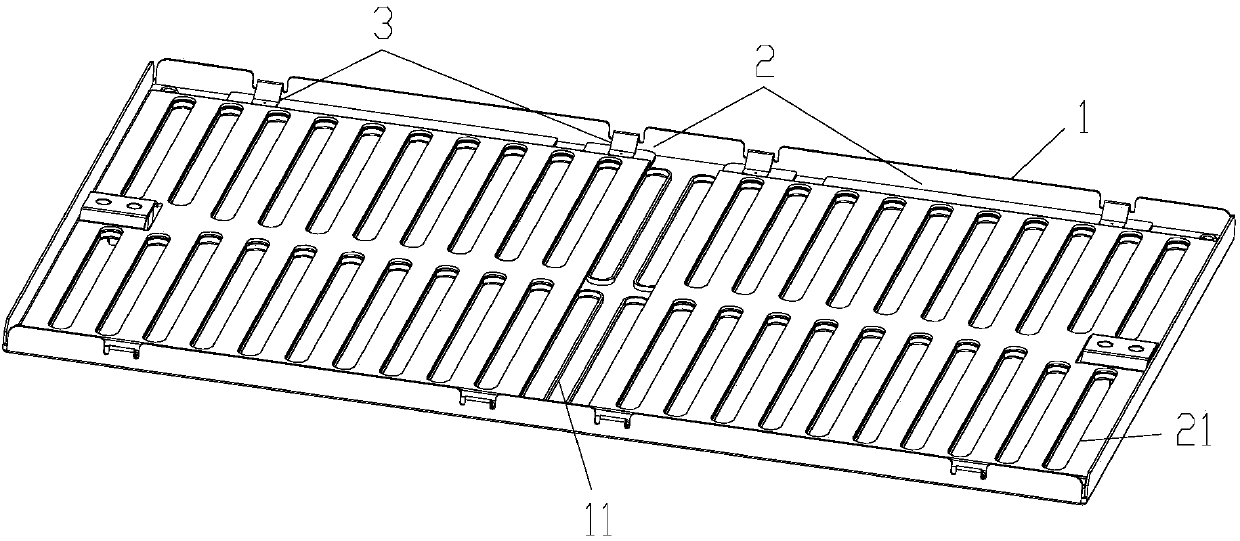

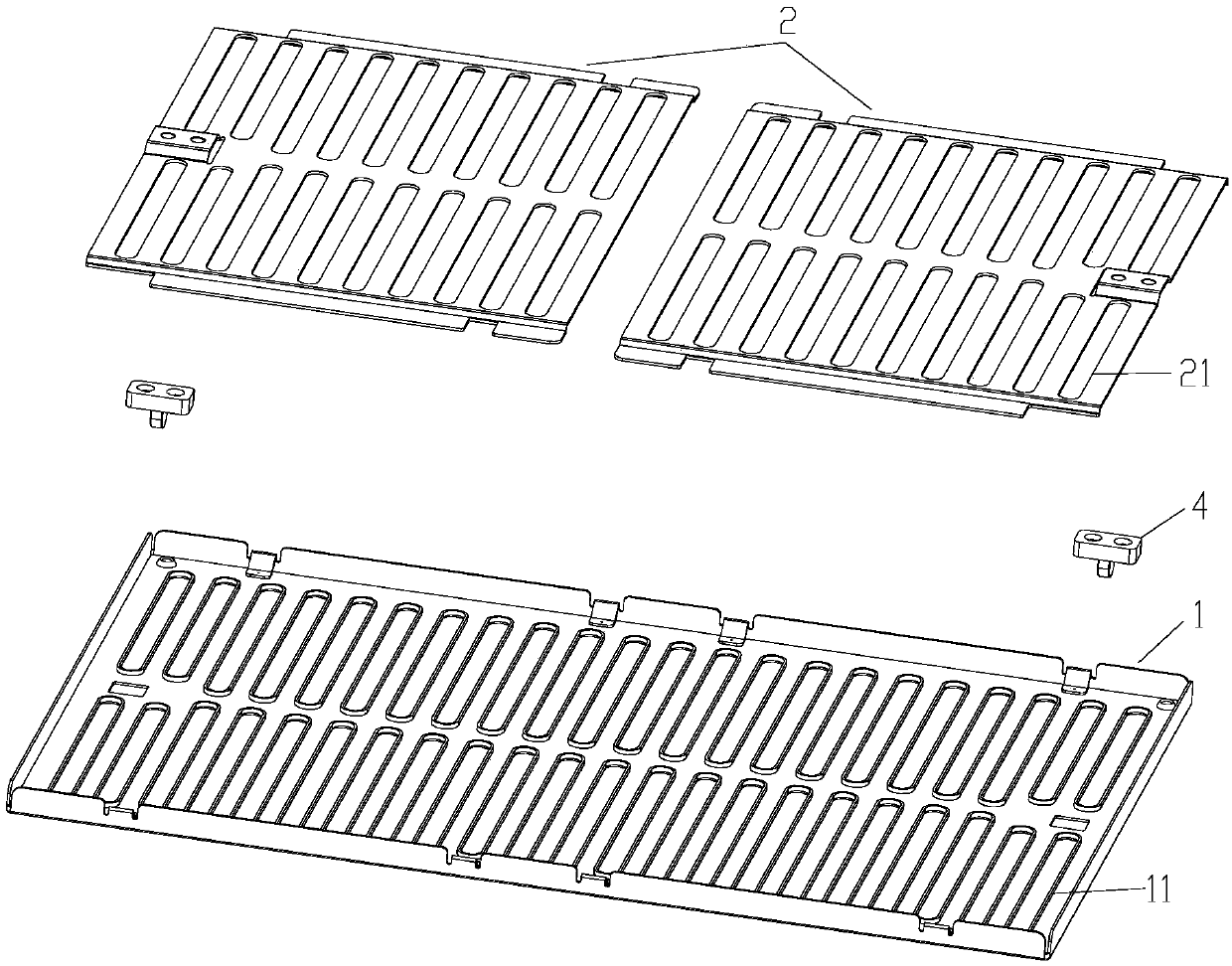

[0027] Such as figure 2 , image 3 As shown, the embodiment of the present invention discloses an oil screen device for a range hood, and the oil screen device includes an outer oil screen 1 , two movable oil screens 2 and a limiting piece 3 . Wherein, the outer oil net 1 is arranged at the air inlet of the range hood, and the two movable oil nets 2 are respectively slidingly arranged on both sides of the outer oil net 1 along the horizontal direction and are located on the upper surface of the outer oil net 1, and the stopper 3 and The outer oil screen 1 is fixedly connected, and the limit piece 3 is tightly pressed on the upper surfaces of the two movable oil screens 2 to limit the movement of the movable oil screen 2 in the vertical direction. When moving the movable oil screen 2 on the left side to the right side of the outer oil screen 1 in the horizontal direction for a certain distance, the second air inlet 21 on the left movable oil screen 2 and the first air hole 21...

Embodiment 2

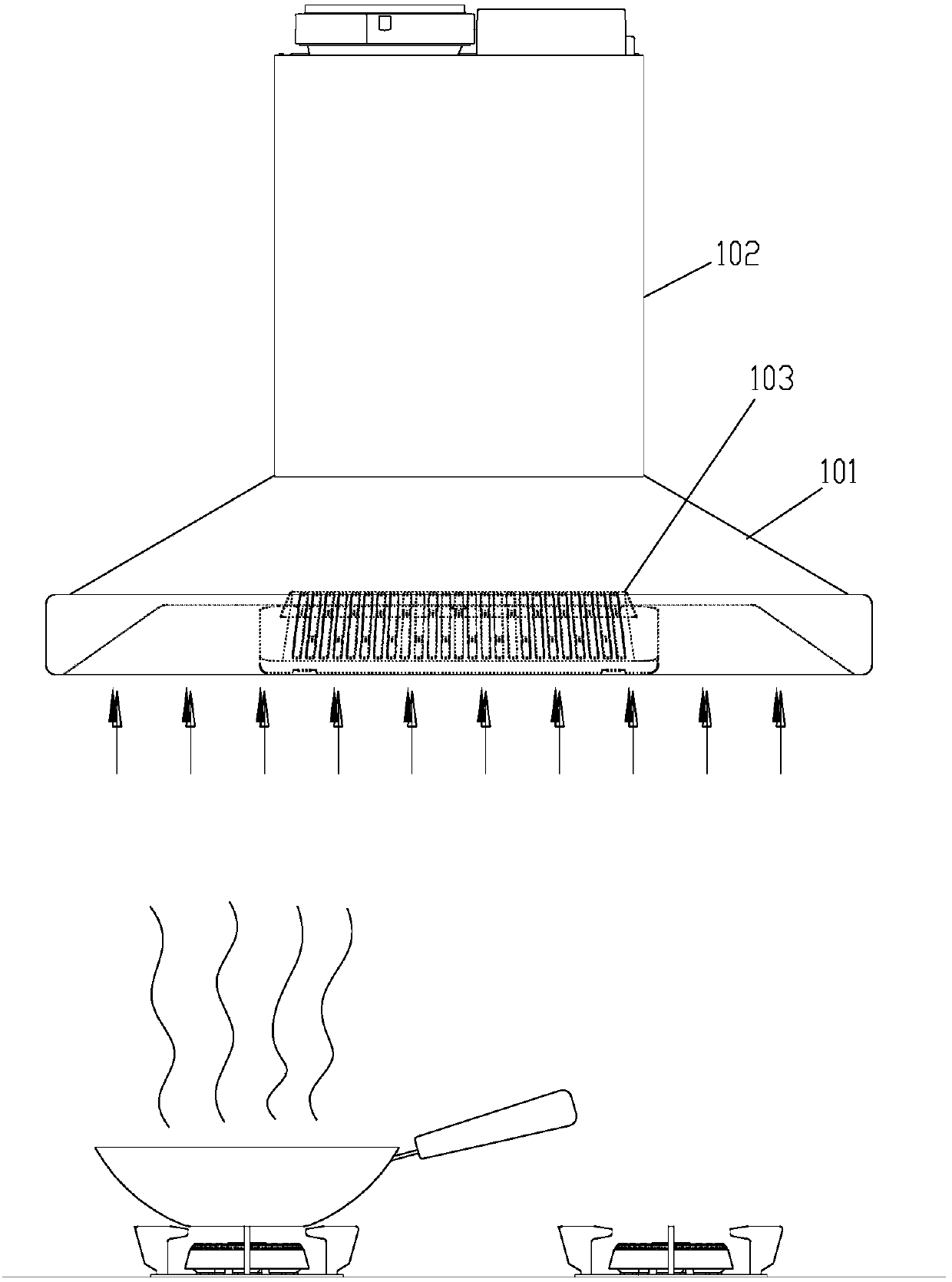

[0035] Embodiment 2 provides a range hood, such as Figure 7 As shown, the range hood includes a box body 5, a fan 6, a smoke collecting hood 7, an air outlet seat 8 and the oil screen device described in Embodiment 1. Wherein, the box body 5 and the smoke collecting hood 7 are fixedly connected, the fan 6 is installed in the box body 5, the air outlet seat 8 is fixed at the air outlet of the fan 6, the smoke collecting hood 7 is provided with an air inlet, and the oil screen device is installed in the The air inlet of fume collecting hood 7.

[0036] Such as Figure 8 As shown, the second air intake holes 21 on the two movable oil screens 2 overlap with the first air intake holes 11 on the outer oil screen 1 respectively. Both sides are in the open state; at this time, except for the air intake holes on the oil net, only the shifting blocks 4 on the left and right sides are exposed, and the appearance is simple and beautiful. If it is necessary to adjust the air intake in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com