multi-channel injector

A jet and multi-channel technology, applied in the field of negative pressure suction equipment, can solve the problems of low nozzle bearing pressure, non-adjustable nozzle, twisted orifice, etc., achieve good cleaning performance, simplify the structure, and increase the bearing pressure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

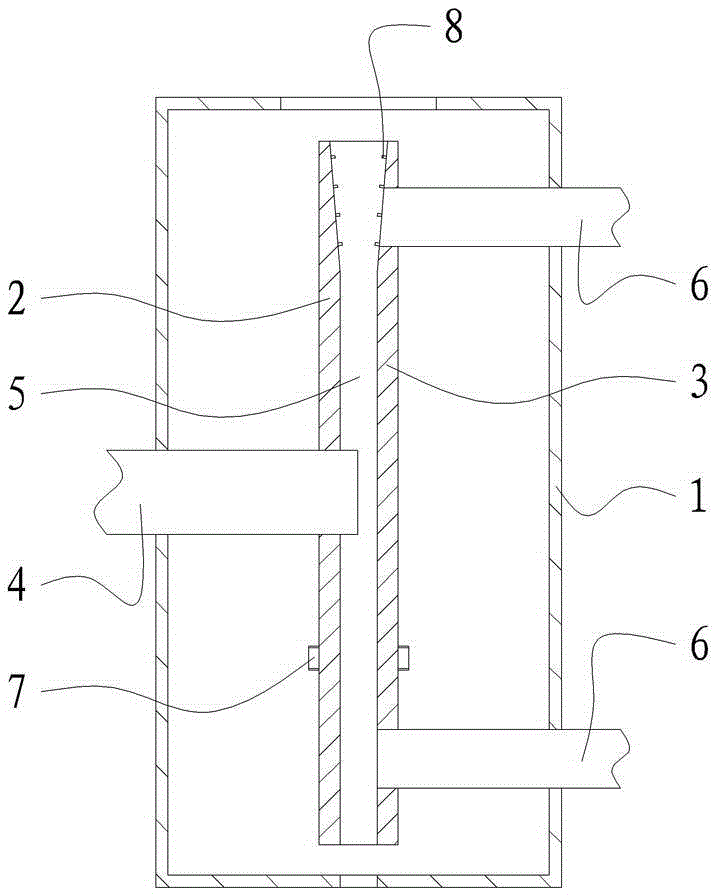

[0017] The multi-channel ejector of the present embodiment, such as figure 1 As shown, it includes a jet box 1 with an outlet. The jet box 1 is provided with a left splint 2 and a right splint 3 that fit each other. The center of the left splint 2 is provided with a jet liquid inlet that passes through the left splint 2 and is perpendicular to the left splint. Tube 4, jet liquid inlet The inlet end of the tube 4 is connected to the outside of the jet box 1 .

[0018] Between the left splint 2 and the right splint 3, a plurality of jet nozzles 5 communicated with the jet liquid inlet pipe 4 are formed, and the plurality of jet nozzles 5 are evenly distributed along the center circumference of the jet liquid inlet pipe 4, and the aperture of each jet nozzle 5 is 8-20mm, the outlet end of each jet nozzle 5 is set opposite to the outlet of the jet box 1, and the edge of the right splint 3 is provided with an air inlet pipe 6 communicating with each jet nozzle 5.

[0019] In this ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com