Operating method of multi-channel jet vacuum pump

A technology of a jet vacuum pump and a working method, which is applied in the field of suction and negative pressure equipment, can solve the problems of low nozzle bearing pressure, unadjustable nozzles, twisted orifices, etc., and achieves the effects of good cleaning performance, simplified structure, and improved bearing pressure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

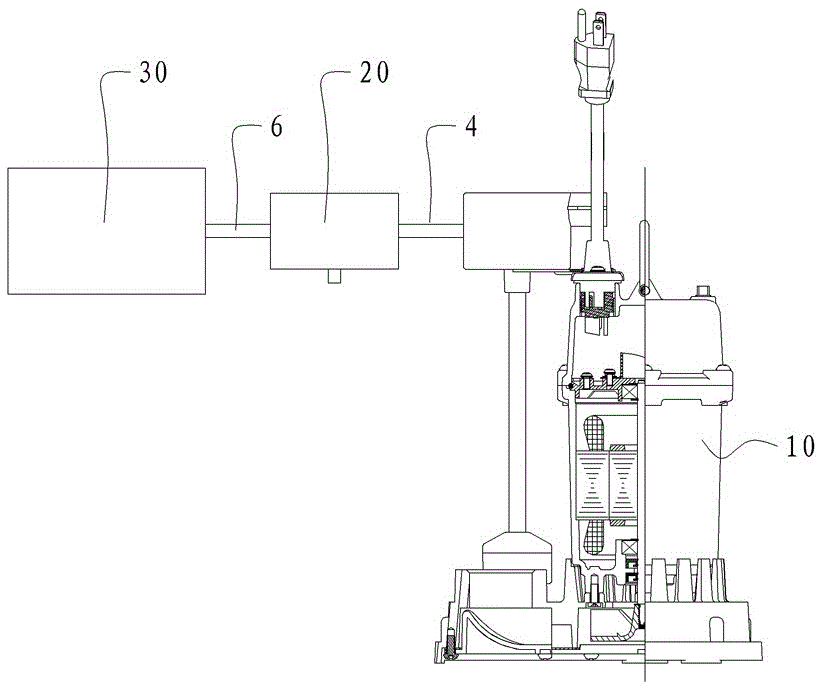

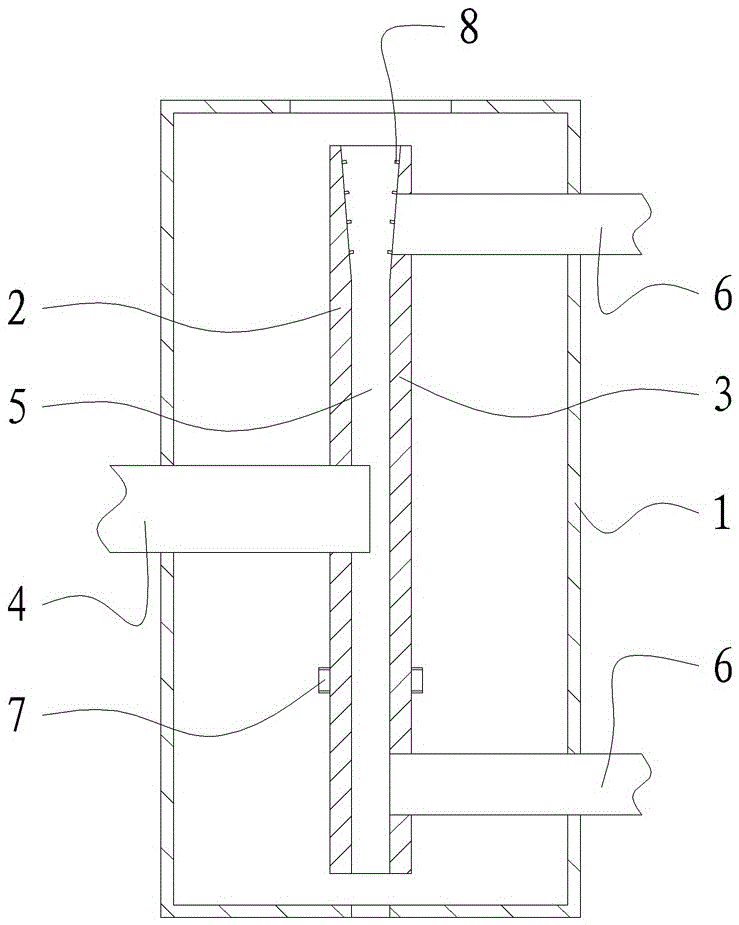

[0018] The multi-channel jet vacuum pump of the present embodiment, as figure 1 and figure 2 As shown, a submersible pump 10 , an ejector 20 and a vacuum tank 30 are included. The jet device 20 includes a jet box 1 with an outlet. The jet box 1 is provided with a left splint 2 and a right splint 3 that fit together. The center of the left splint 2 is provided with a jet liquid inlet that passes through the left splint 2 and is perpendicular to the left splint. Pipe 4, the inlet end of the jet liquid inlet pipe 4 is connected to the outlet of the submersible pump 10 .

[0019] Between the left splint 2 and the right splint 3, a plurality of jet nozzles 5 communicated with the jet liquid inlet pipe 4 are formed, and the plurality of jet nozzles 5 are evenly distributed along the center circumference of the jet liquid inlet pipe 4, and the aperture of each jet nozzle 5 is 8-20mm, the outlet end of each jet nozzle 5 is set opposite to the outlet of the jet box 1, and the edge o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com