Cold storage condensation water collecting device

A water collection device, frost water technology, applied in household refrigeration devices, defrosting, household appliances, etc., can solve the problem of wasting manpower for cleaning, etc., and achieve the effect of increasing safety risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The technical solutions and technical effects of the present invention will be further described in detail below in conjunction with the accompanying drawings of the present invention.

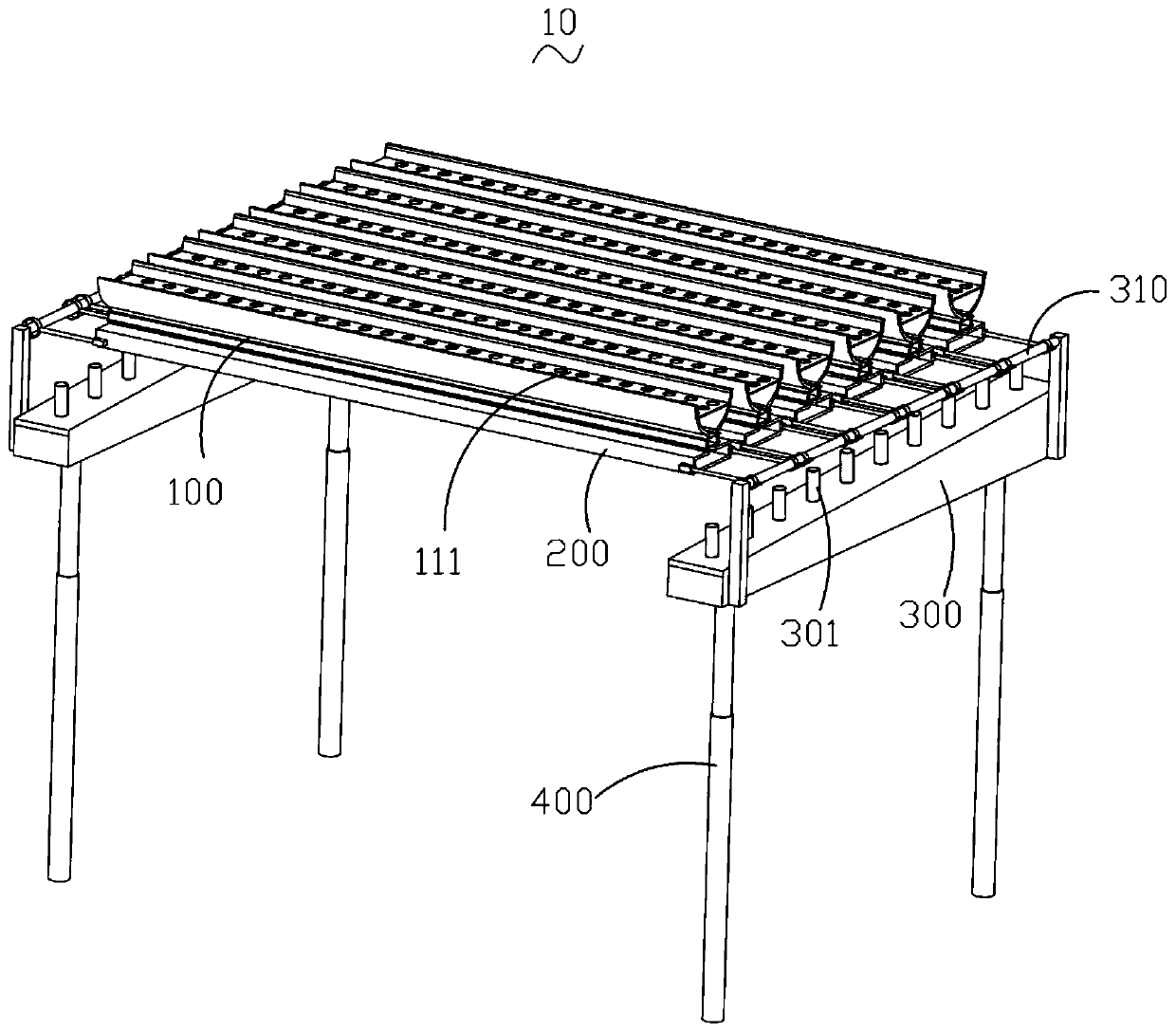

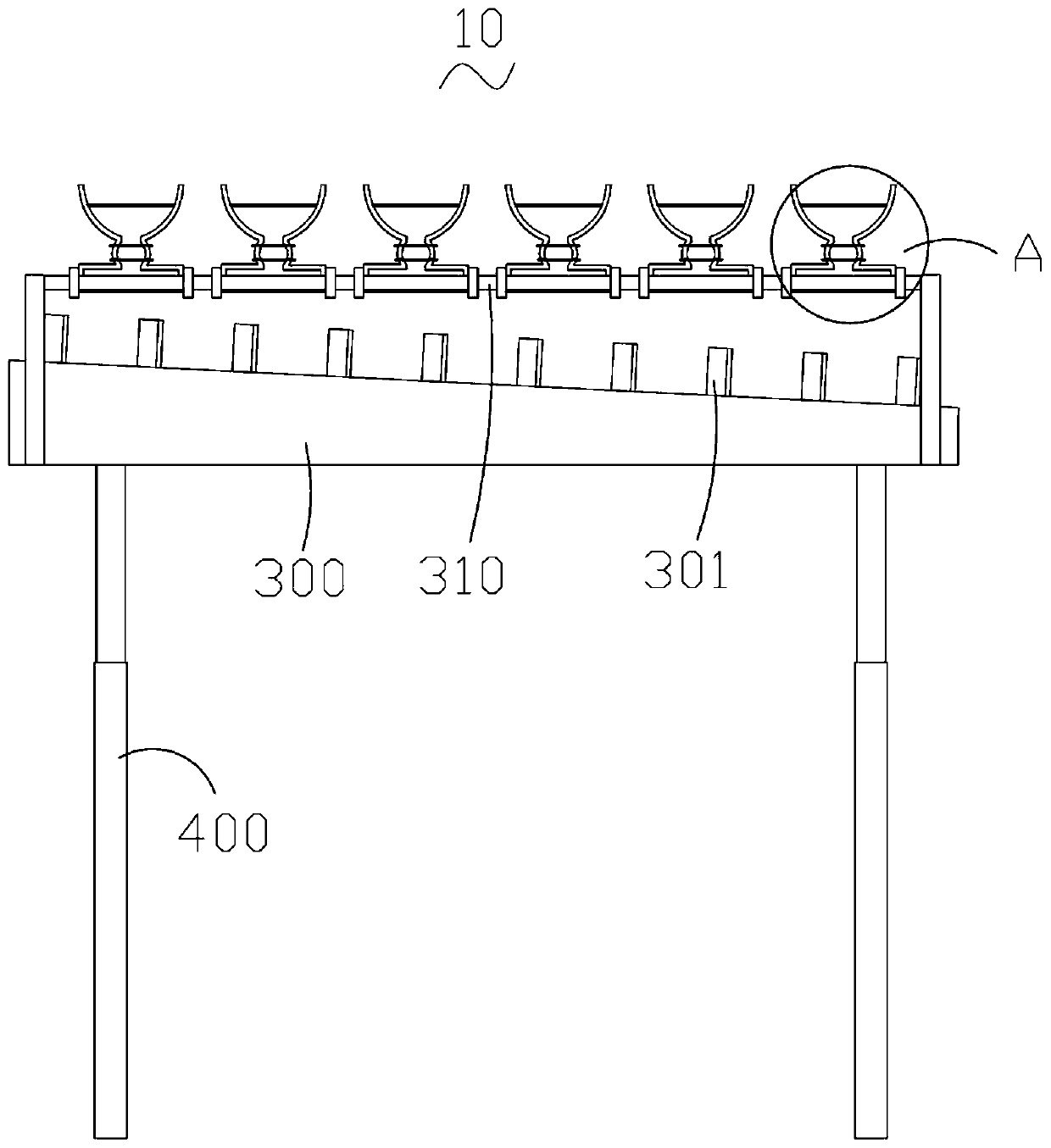

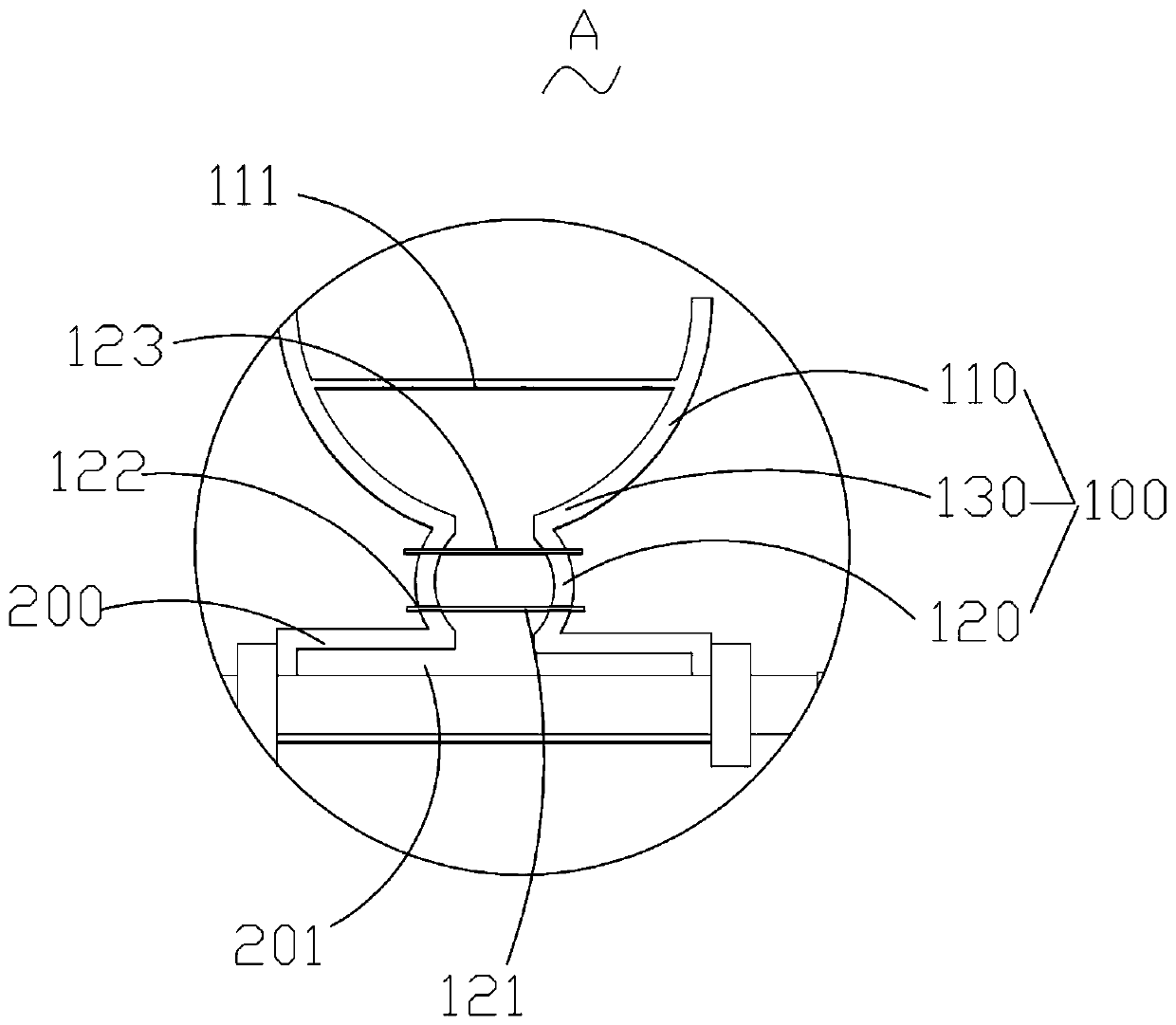

[0028] Please see Figure 1 to Figure 3 , in a specific embodiment, a cold storage defrost melting water collection device 10 is used to collect the melting water generated in the process of melting and defrosting in the cold storage, including: several frost water receiving parts 100, several diversion pipe parts 200, Frost water is exported to the main pipe 300 and the support rod 400 .

[0029] A plurality of the frost water receivers 100 are arranged side by side and installed under the refrigeration coil of the cold storage to collect the melted water or the falling off incompletely melted frost during the defrosting process of the cold storage. The diversion pipe 200 is arranged below the frost water receiving part 100 and is parallel to the frost water receiving part 100. The di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com