PE welding pipe leakage detection device

A technology for pipe fittings and leak detection, which is applied in the direction of liquid tightness measurement using liquid/vacuum degree, etc. It can solve the problems of easily damaged pipe fittings, cumbersome operations, and easy misjudgment operations, so as to ensure test accuracy, improve production efficiency, Strong linkage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

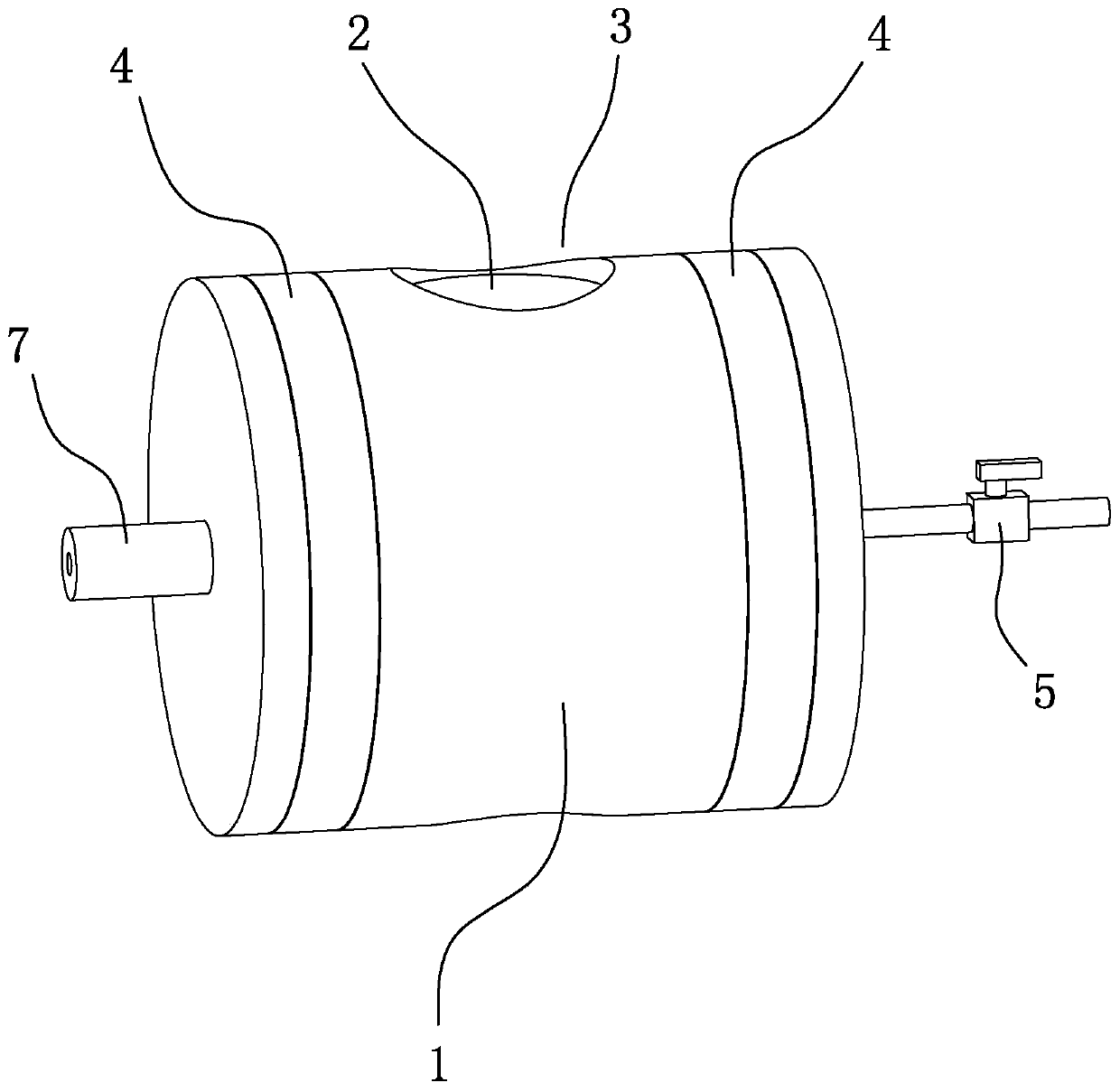

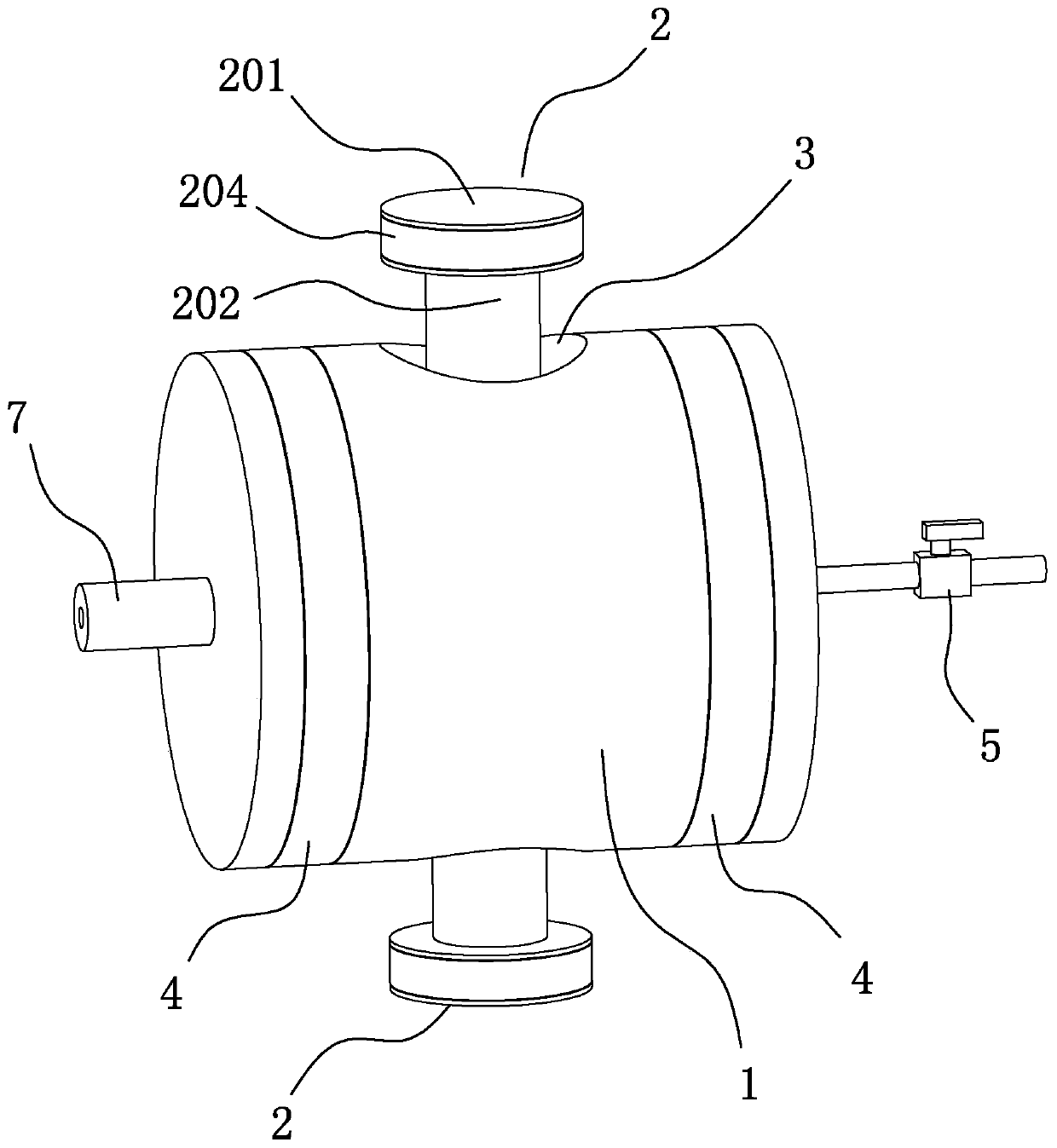

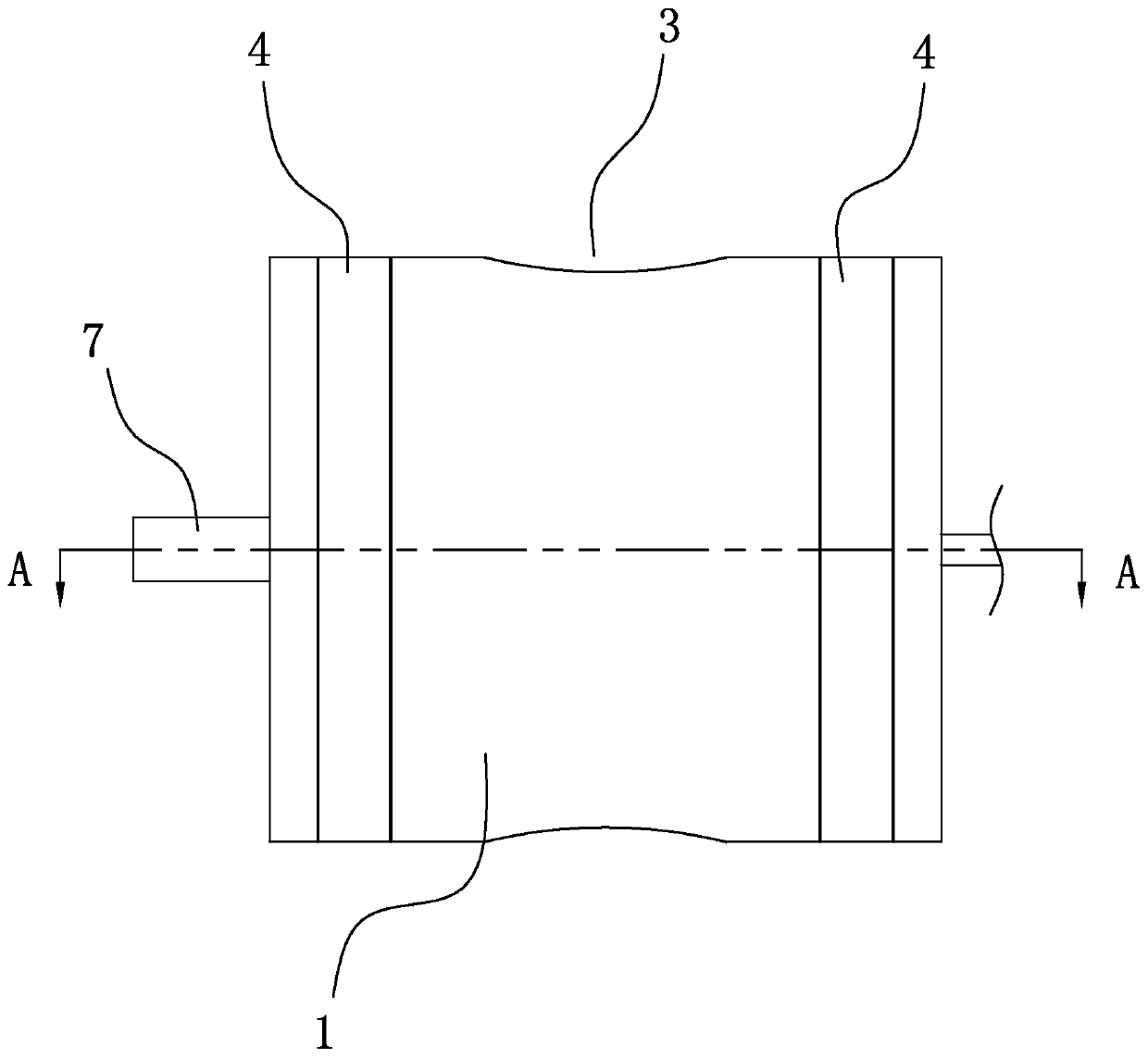

[0028] see Figure 1 to Figure 10 , a leak detection device for PE welded pipe fittings described in this embodiment includes a main body 1 and two lifting bodies 2 .

[0029] The main body 1 is columnar, and the outer wall of the main body 1 is provided with two first sealing ring accommodation grooves, and each first sealing ring accommodation groove is provided with a main pipe 801 for fitting and sealing the four-way joint 8 The first inflatable sealing ring 4 on the inner wall, the two first inflatable sealing rings 4 are arranged coaxially with the main body 1 , and the main body 1 is provided with a connecting channel 101 for connecting the two first inflatable sealing rings 4 .

[0030] A columnar sliding hole 3 is opened radially in the middle of the outer wall of the main body 1 , and two first inflatable sealing rings 4 are located ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap