Safety type hydraulic electromagnetic circuit breaker and breaking method

A circuit breaker and safety-type technology, which is applied in the field of circuit breaker manufacturing, can solve the problems of long separation time, etc., and achieve the effects of improving safety and reliability, reducing breaking time, and improving breaking capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

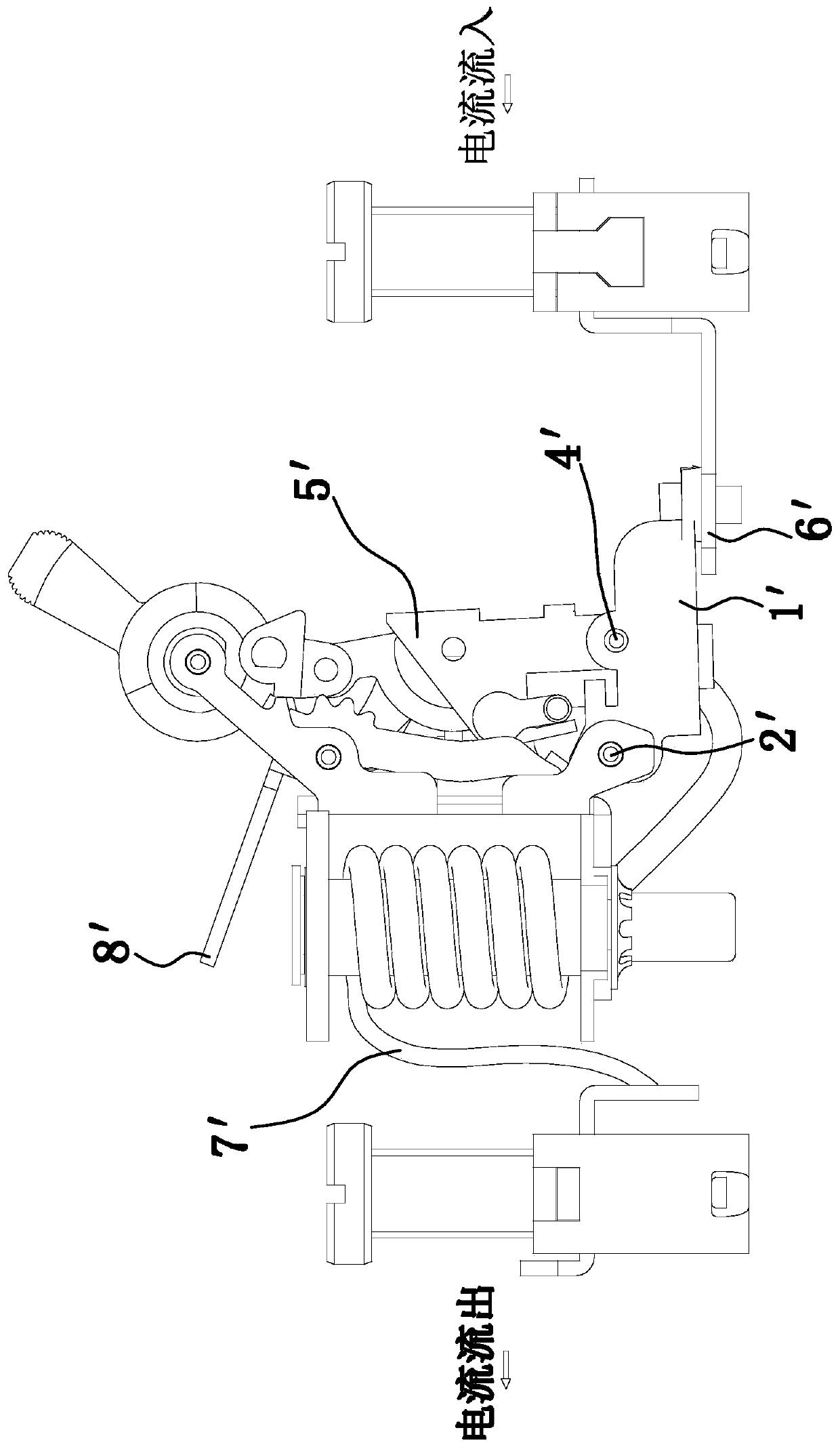

[0036]The safety type hydraulic electromagnetic circuit breaker includes a housing 1, on which is provided an incoming line terminal 2 and an outgoing line terminal 3, and an electromagnetic transmission mechanism 4 is provided between the incoming line terminal 2 and the outgoing line terminal 3, and the electromagnetic transmission mechanism 4 includes The induction coil 402 wound on the delay tube 401, the delay tube 401 is set on the installation frame 403, and also includes a tripping mechanism 404, an armature 405 and a hand brake 406, and the installation frame 403 respectively passes through the fourth hinge 407, the second The five hinges 408 are hinged with the armature 405 and the hand brake 406, the tripping mechanism 404 is hinged with the hand brake 406 through the third hinge 409, the tripping mechanism 404 is also hinged with the moving contact 411 through the first hinge 410, and the moving contact 411 is provided with a movable contact 412, and the static cont...

Embodiment 2

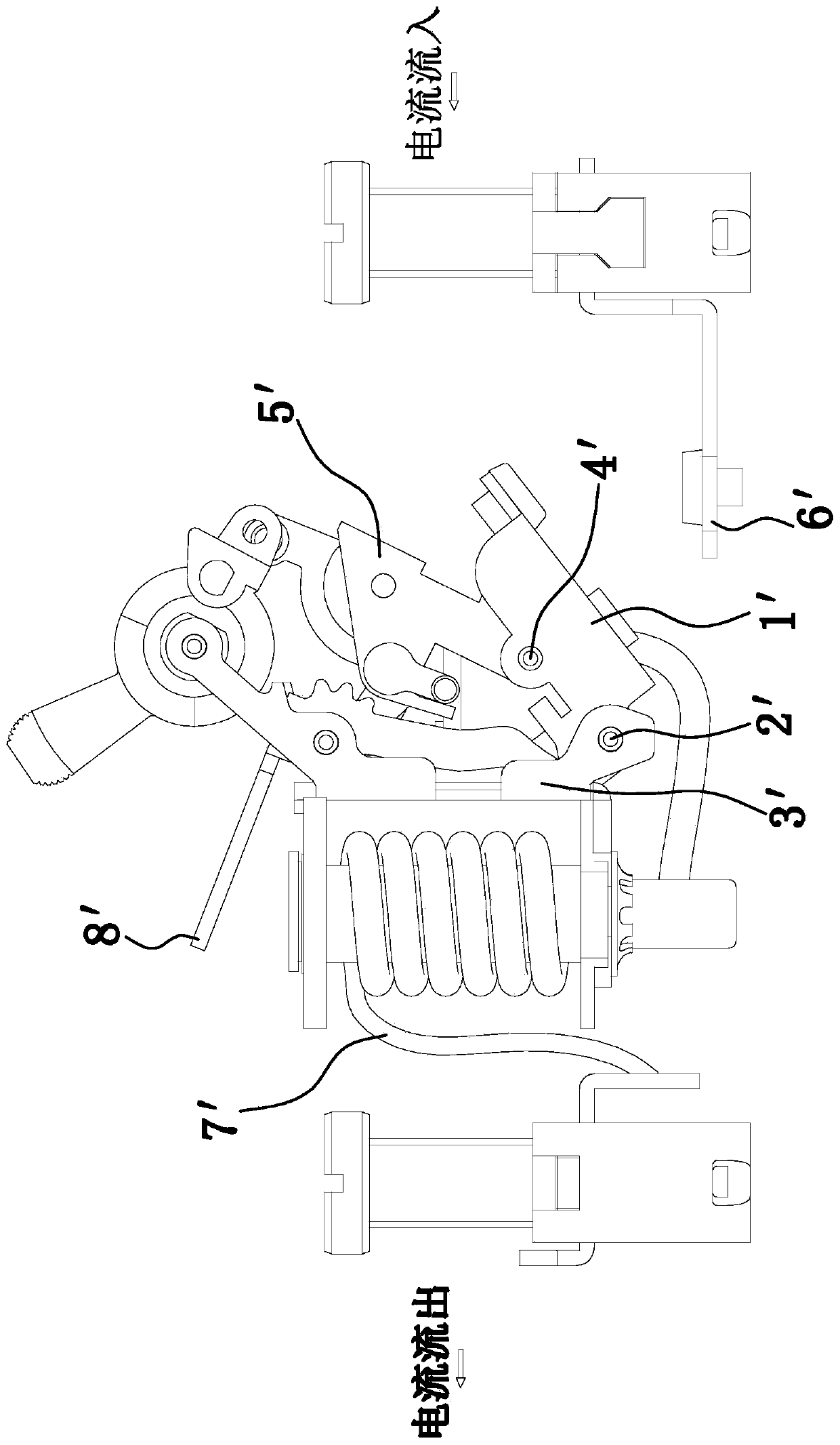

[0044] This embodiment is basically the same as Embodiment 1, except that the electromagnetic transmission mechanism 4 also includes an elastic clamping seat 419 arranged on the housing 1. When the switch is closed, the elastic clamping seat 419 and the Pushed by the electric repulsive force, the movable contact 411 that rotates around the first hinge 410 away from the fixed contact 413 is snap-fitted, so as to prevent the rotating movable contact 411 from rotating. Because if the moving contact 411 rotates away from the static contact 413 by the electric repulsion force, and the induction coil 402 has not attracted the armature 405, the armature 405 will not drive the release mechanism 404 to unlock. Small, the movable contact 411 may turn around, causing the movable contact 412 on the movable contact 411 and the static contact 414 on the static contact 413 to combine again, which may cause danger, and after the elastic clamping seat 419 is set Therefore, only after the tripp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com