Differential connector and installation structure of bent contact

A technology for differential connectors and installation structures, which is applied in the direction of contact parts, parts of connection devices, fixed/insulated contact members, etc. It can solve the problems of difficult assembly of curved contacts, achieve simple form, ensure stability, and cooperate The effect of stable relationships

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

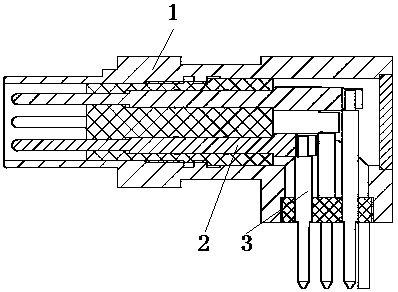

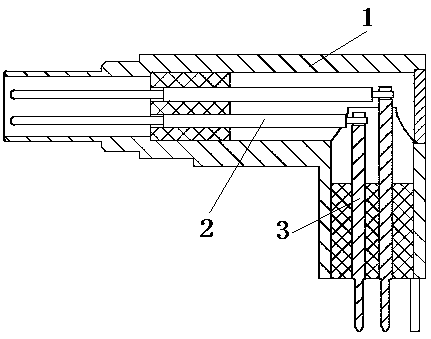

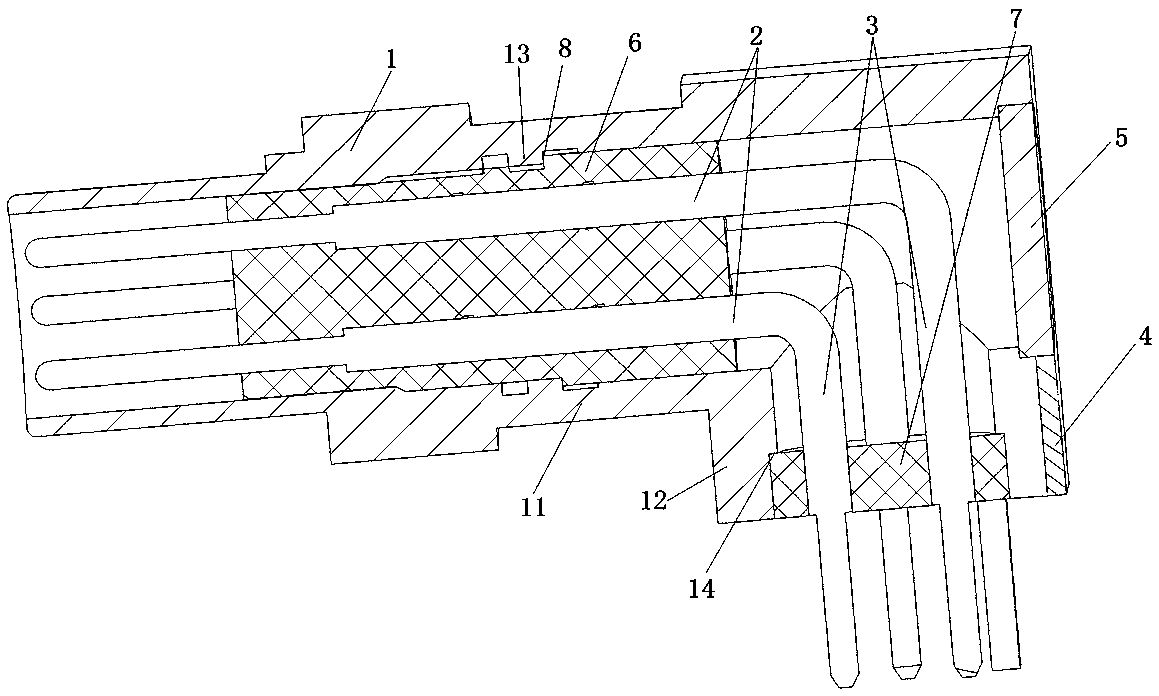

[0050] like Figure 3 to Figure 4 As shown, it is Embodiment 1 of the differential connector in the present invention: the differential connector includes two parts, respectively an outer conductor 1 and a center conductor arranged in the outer conductor 1, and the center conductor is L-shaped, respectively including a horizontal direction. The horizontal section conductor 2 and the vertical section conductor 3 arranged in the vertical direction and perpendicular to the horizontal section conductor 2, and the horizontal section conductor 2 and the vertical section conductor 3 are integrally constructed, and have been assembled before the outer conductor 1 is assembled. Fixed connection.

[0051] In order to ensure that the integrated L-shaped center conductor can be smoothly assembled into the outer conductor 1, the outer conductor 1 is provided with an escape port 4 for inserting the horizontal conductor 2 in the center conductor into the outer conductor 1. The horizontal se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com