Cable laying device

A cable laying and cable technology, which is applied in the field of cable laying devices, can solve the problems of low working efficiency of laying cables, and achieve the effects of stable laying, improving friction and improving working efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

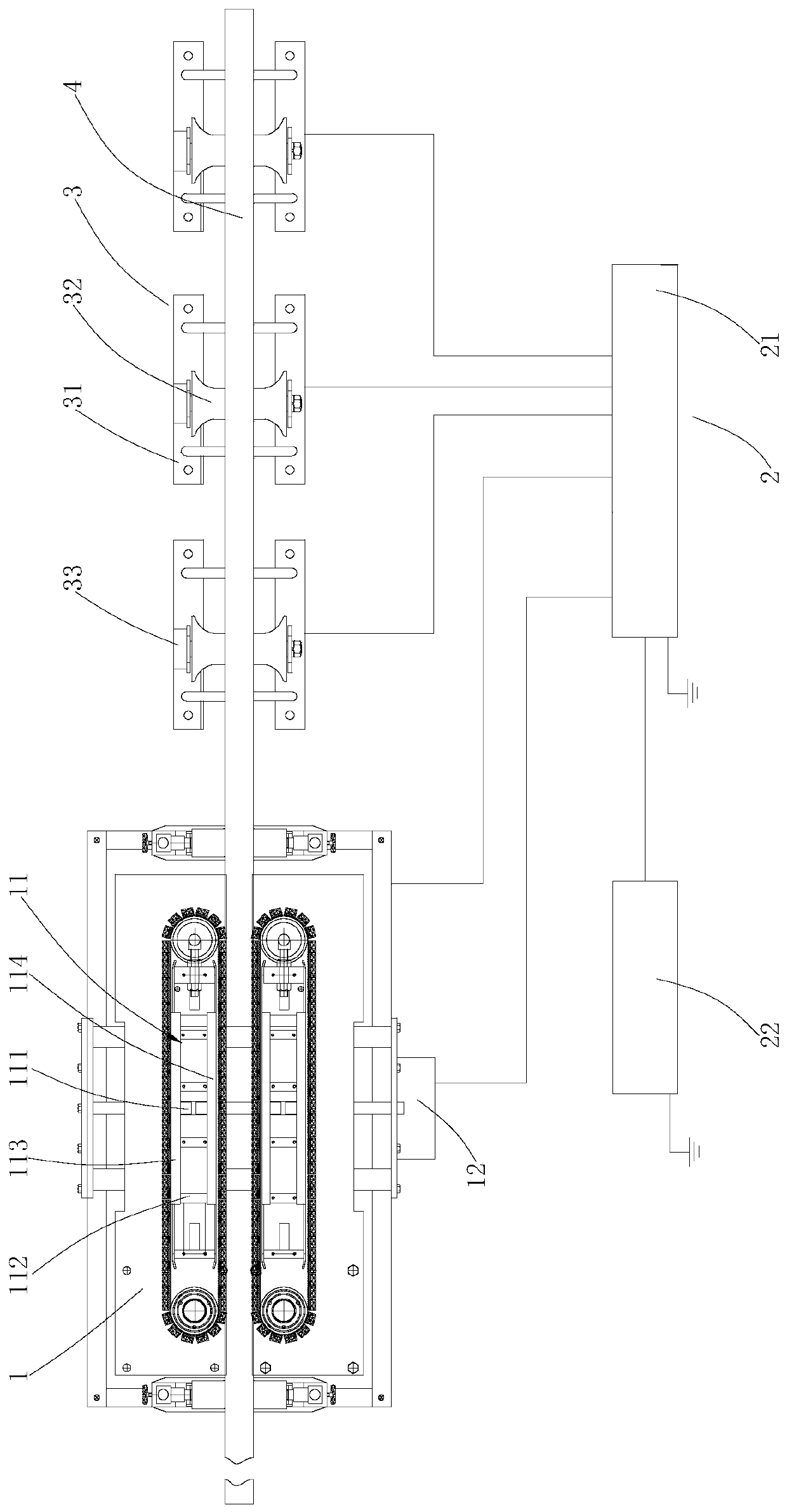

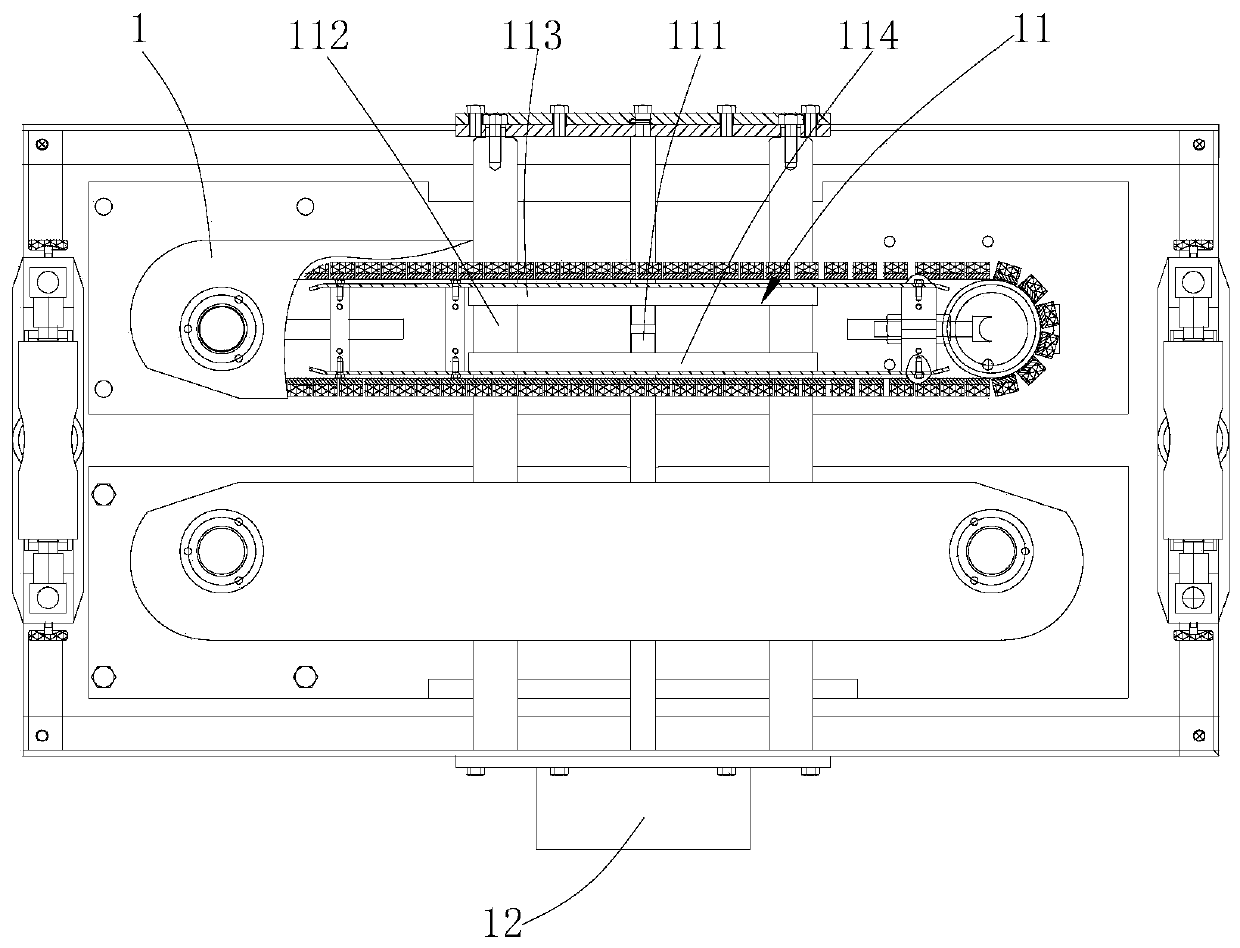

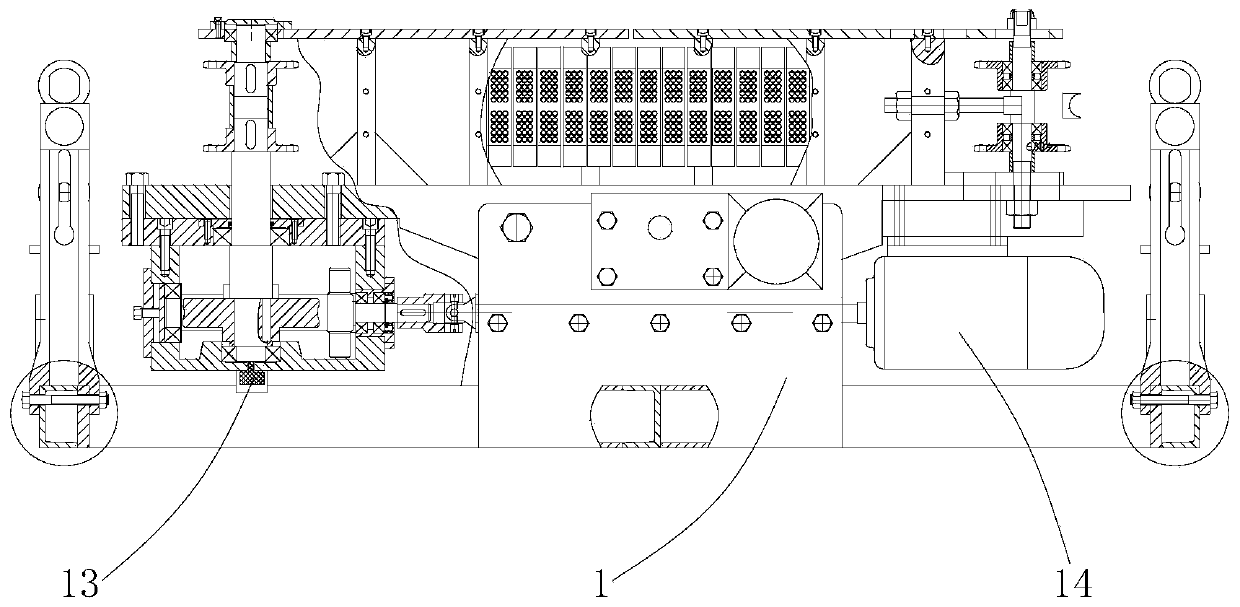

[0052] see figure 1 , Figure 4 and Figure 5 , as a specific embodiment of the cable laying device provided by the present invention, the high-voltage input and output cabinet 21 includes a cabinet body 211, a controller 212 and a power supply 213, and the cabinet body 211 is arranged on one side of the conveyor 1; the controller 212 is arranged on The cabinet 211 is electrically connected to the conveyor 1; the power supply 213 is located in the cabinet 211 and electrically connected to the controller 212, and the controller 212 and the power supply 213 are placed in the cabinet 211 to isolate them from the outside world; When in use, connect the power supply 213 and the controller 212 to the conveyor 1 and the torque motor respectively, and the controller 212 controls the startup, operation and shutdown of the conveyor 1 so that the cable laying device can work normally. When the distance between the two conveyors 113 and 114 is reduced, the controller 212 can control the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com