A kind of plastic particle regeneration mould device

A technology of plastic granules and forming molds, which is applied in sorting and other directions, can solve the problems of plastic quality and plastic color, and achieve a good collection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Please refer to Figure 1 to Figure 10

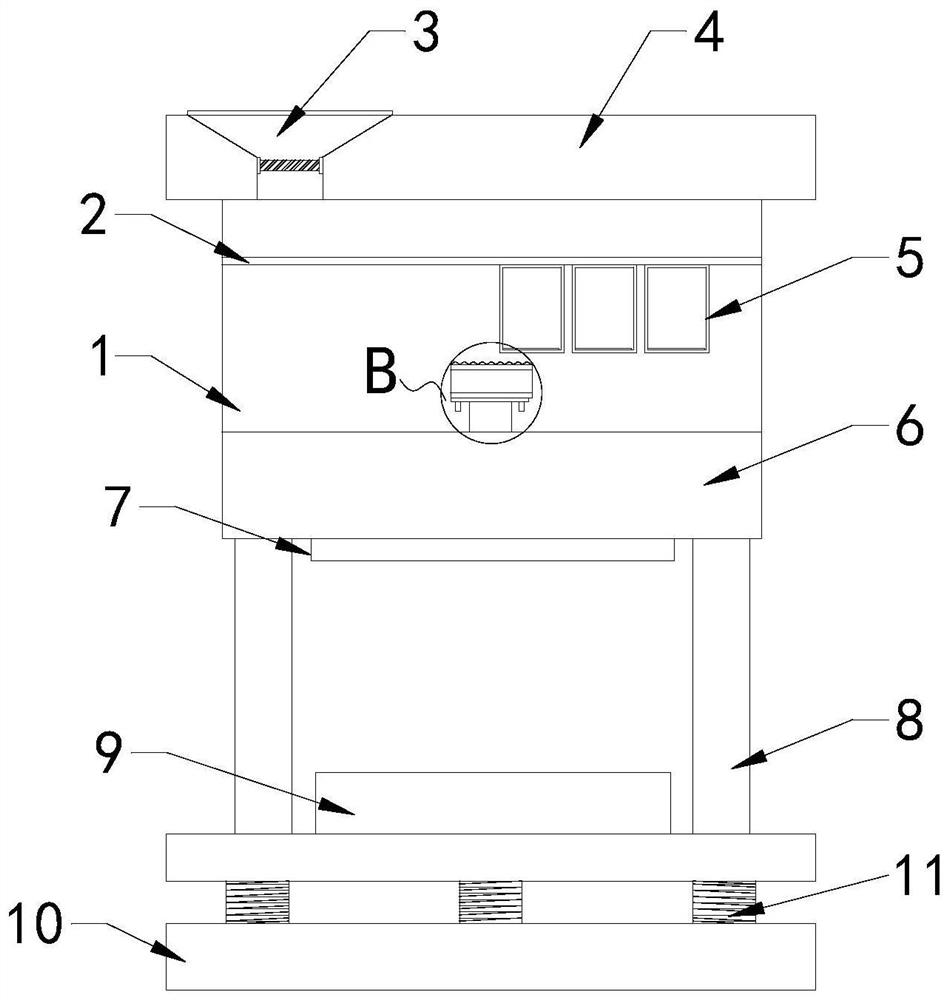

[0029] The present invention proposes a mold device for regeneration molding of plastic particles, comprising: a mold device 1, an upper mold base 4, a lifting rod 8, a template 9 and a lower mold base 10; the inside of the mold device 1 is provided with a working cavity 6, and the mold device The bottom of the 1 is fixedly connected with a lifting rod 8, and the upper mold base 4 is embedded with a feed port 3.

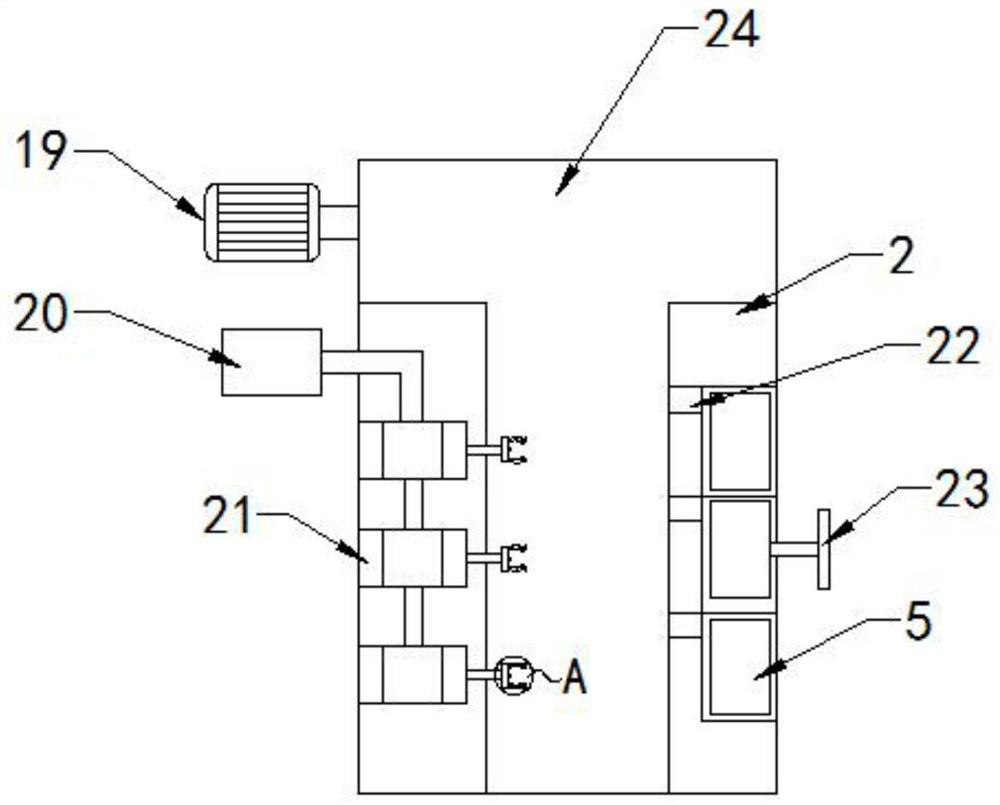

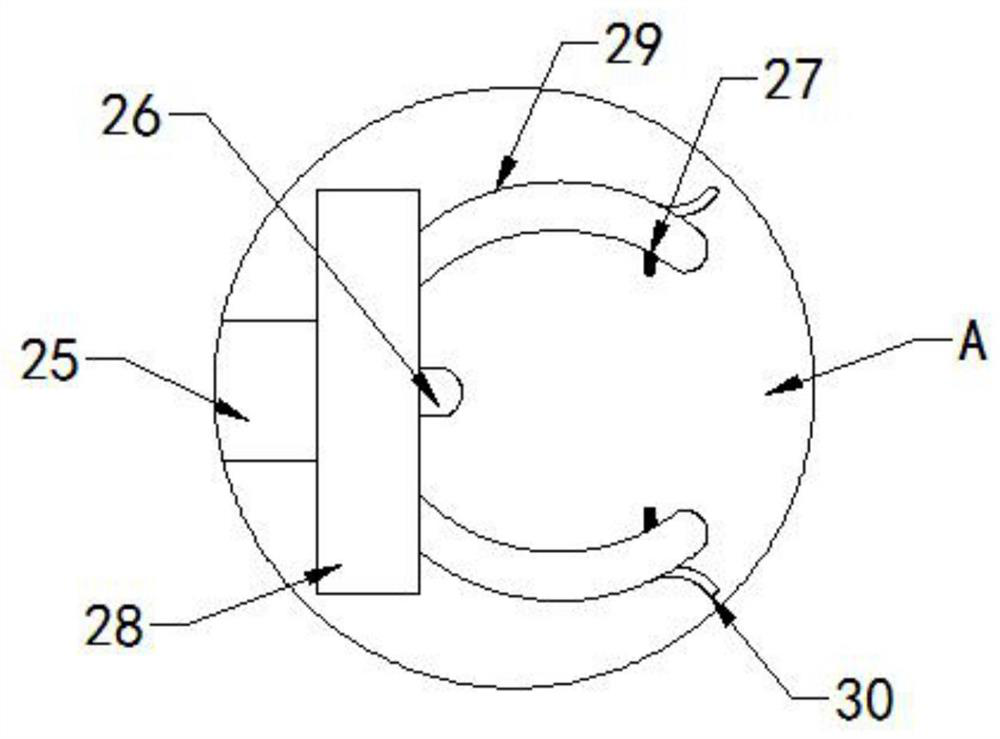

[0030] Simultaneously, mold device 1 inside includes horizontal plate 2 and working cavity 6, and the left end of horizontal plate 2 is provided with motor 19, and motor 19 is distributed on the outer wall of mold device 1, and one end of motor 19 is provided with solenoid valve 20, drives electromagnetic The valve 20 controls the cylinder 21 to push the plastic pellets.

[0031] At the same time, one end of the horizontal plate 2 is provided with at least three collection boxes 5, and the top of the collection box 5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com