Wind power type offshore embarkation walking bridge

A bridge and wind power technology, which is applied to ships, cargo handling equipment, passenger handling equipment, etc., can solve the problems of high protection requirements, less freedom, increased operation and maintenance, and rescue costs, so as to improve safety and durability, Simplify the structure and improve the effect of protective measures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below with reference to the accompanying drawings and specific embodiments.

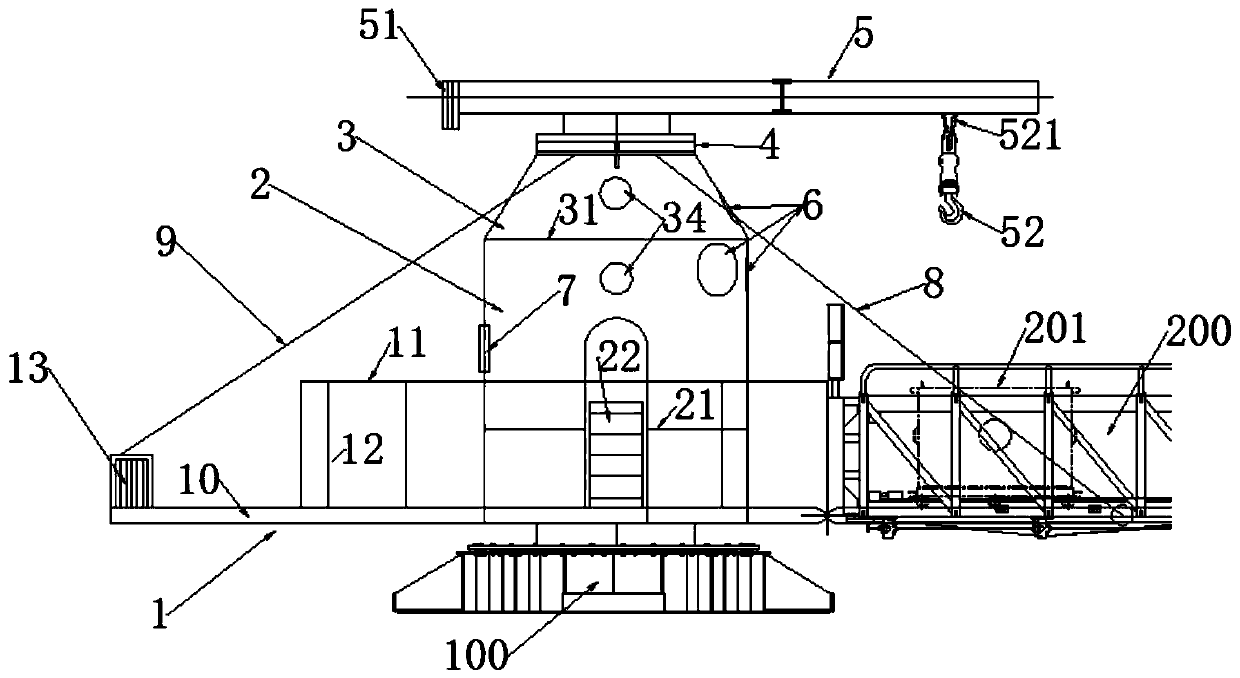

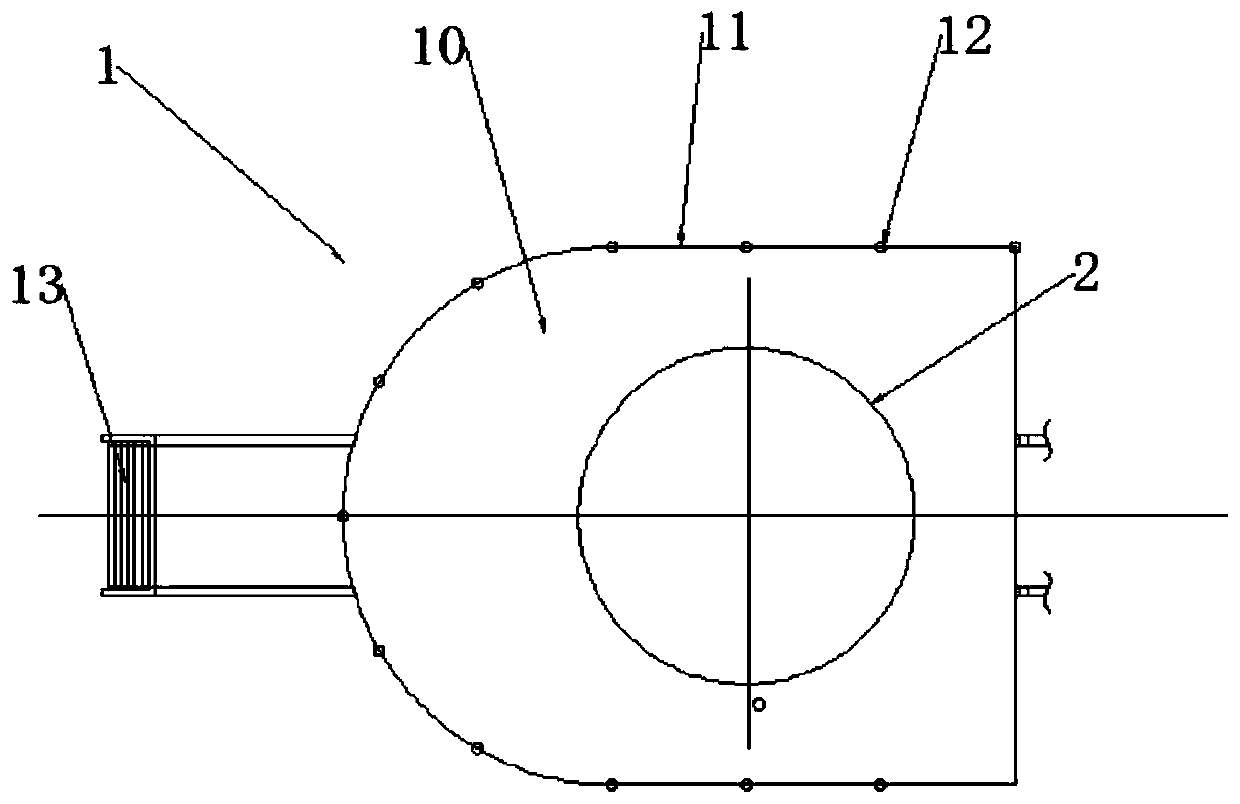

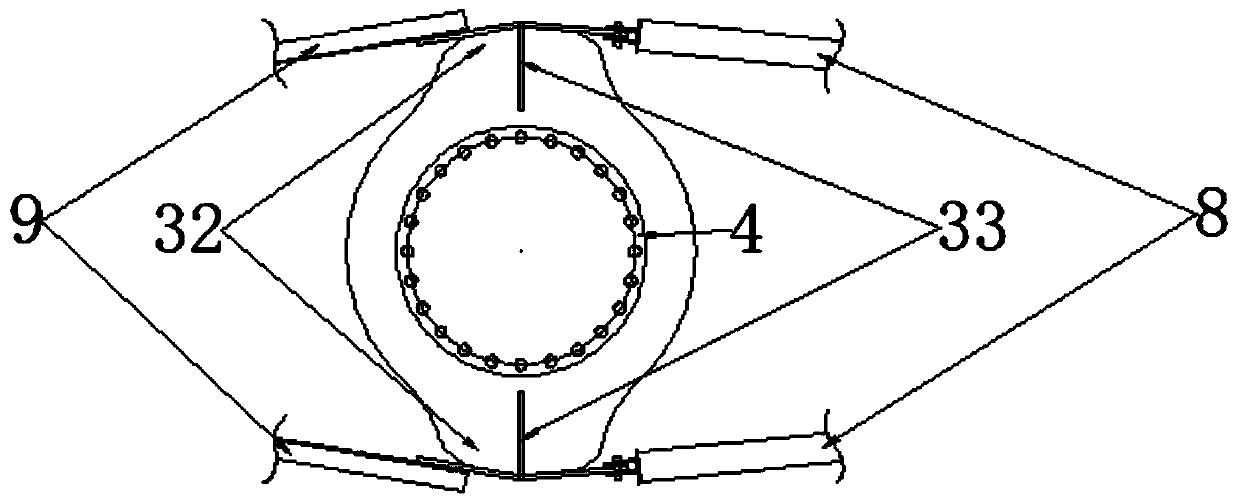

[0031] see Figure 1 to Figure 6 As shown, the present invention provides a wind power type offshore boarding bridge, which includes a motion compensation platform and a bridge ladder 200, and also includes a walking bridge base 1, such as figure 2 shown,

[0032] The step bridge base 1 includes a bottom plate 10 for connecting the slewing base 100 of the motion compensation platform, and a circular handrail 11 is arranged on the periphery of the bottom plate 10, which is used as a seat belt hooking place and a hand grip for operation and maintenance personnel when they are to be transferred. In order to avoid accidents when the operation and maintenance ship has a large sway, the bottom end of the annular handrail 11 is connected with a plurality of pillars 12, and the annular handrail 11 is connected to the bottom plate 10 through the plurali...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com