Wind power sea oil type sea boarding gangway bridge

A bridge and CNOOC technology, which is applied to ships, cargo handling equipment, passenger handling equipment, etc., can solve the problems of less equipment freedom, high protection requirements, and low equipment efficiency, and achieve structural weight reduction and simplified structural form , the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

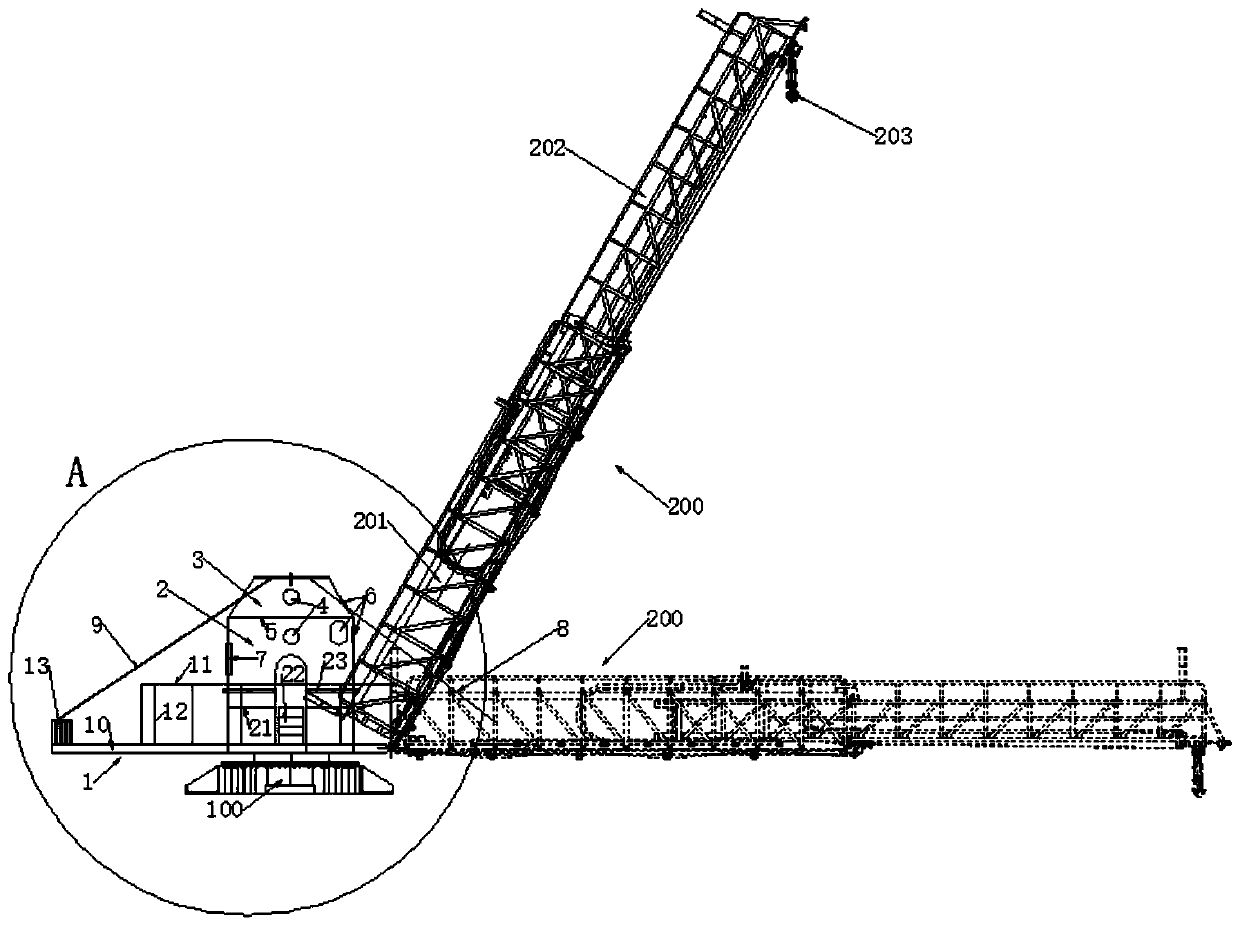

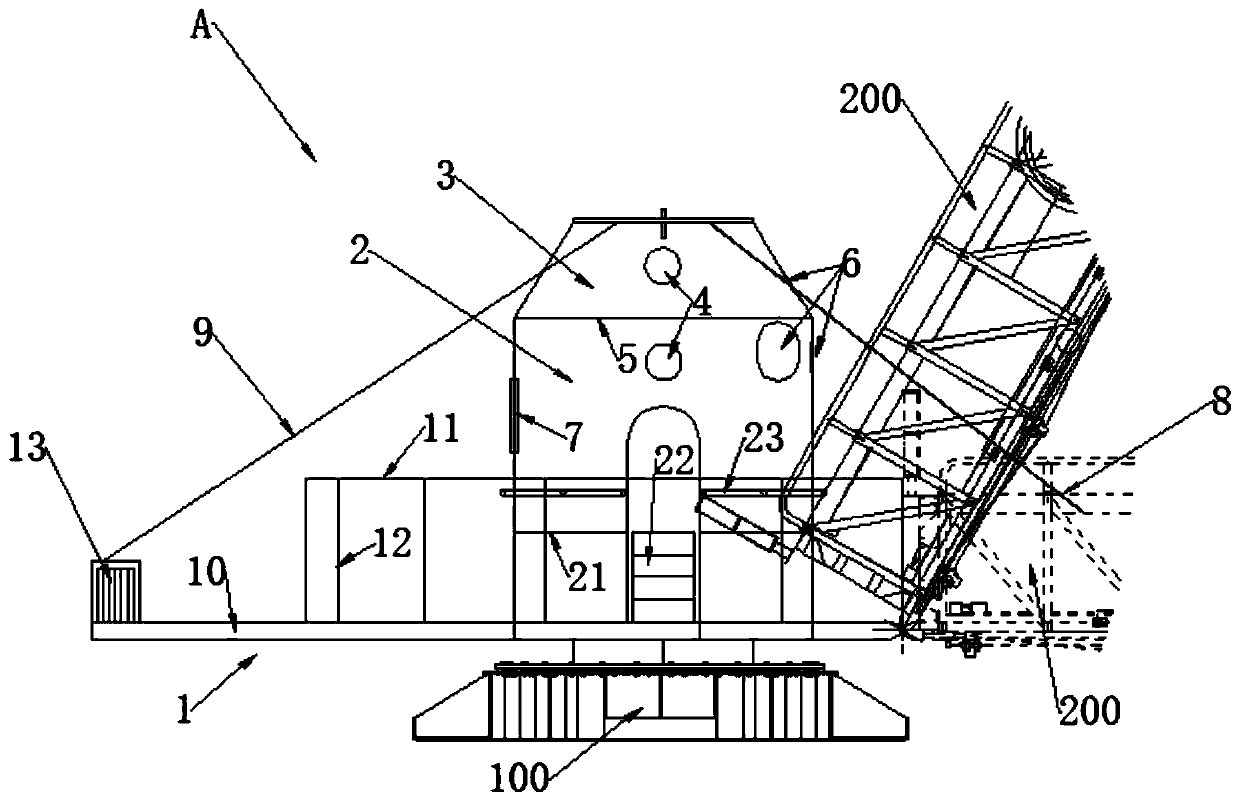

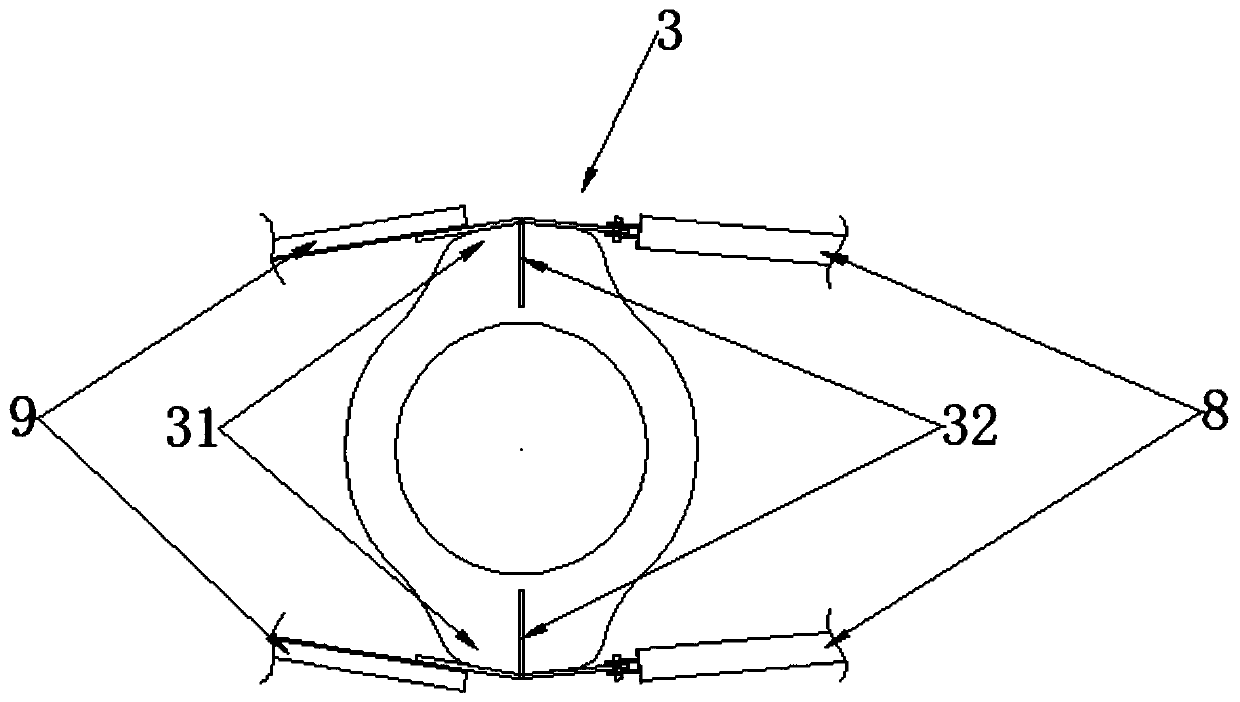

[0033] refer to Figure 1 to Figure 6 As shown, the present invention provides a wind power sea oil type offshore boarding step bridge, including a motion compensation platform 100 and a bridge ladder 200, and also includes a step bridge base 1, and the step bridge base 1 includes a bottom plate 10 for Connect the rotary base of the motion compensation platform 100, the periphery of the bottom plate 10 is provided with a ring handrail 11, the bottom end of the ring handrail 11 is connected with several pillars 12, and the ring handrail 11 passes through the several pillars 12 Connect the base plate 10; the left end of the base plate 10 is provided with a base plate counterweight 13, the right end of the base plate 10 is hinged to the bridge ladder 200, the upper end of the base plate 10 is provided with a cylindrical shell 2, and the cylindrica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com