Tension damper

A damper and tension technology, which is applied in the direction of winding strips, conveying filamentous materials, thin material processing, etc., can solve the problem that the damping force output control curve cannot maintain linearity, etc., to increase the output adjustment range and improve The effect of production quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

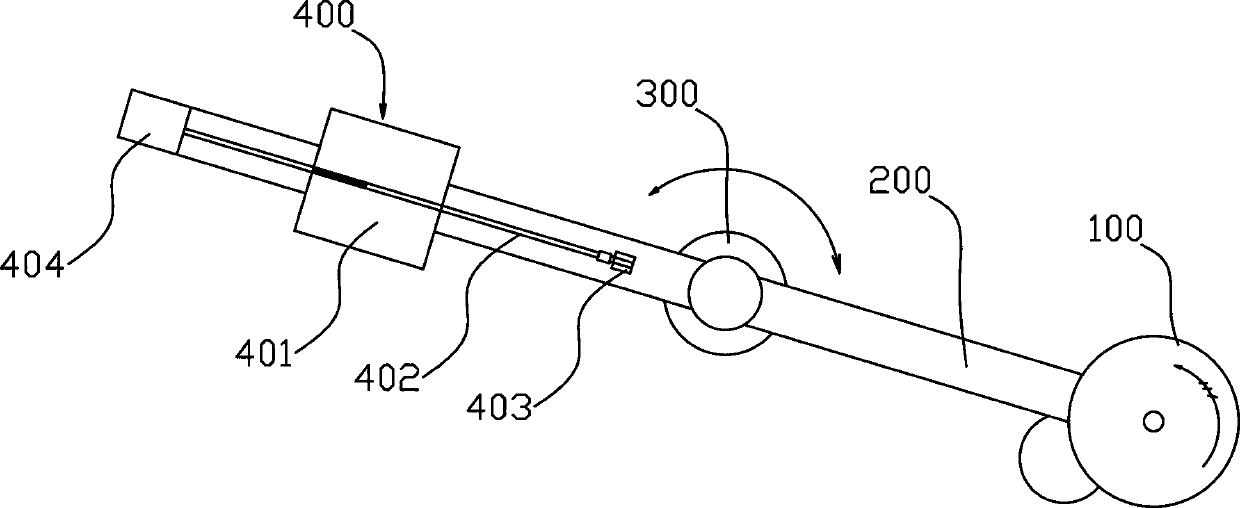

[0037] Such as figure 1 Among them, a tension damper, the balance bar 200 is rotatably installed on the balance base 300, and the balance base 300 is provided with an angle sensor for detecting the rotation angle of the balance bar 200; the set angle sensor is actually used for feedback on the wire or The tension of the strip 700 varies.

[0038] Bounded by the rotation axis of the balance base 300, a damper 100 is provided at one end of the balance pole 200, and the damper 100 is used to provide resistance for the wire or strip 700 to travel;

[0039] The other end of the balance bar 200 is provided with a slider device 400 that can adjust its position along the balance bar 200 . This structure can provide high-precision tension and high-precision resistance for the wire or strip 700 .

[0040] The preferred solution is as figure 1 In the slider device 400 described above, the counterweight slider 401 is slidably connected to the balance bar 200 , the screw rod 402 is rotat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com