Picker applicable to high-impurity-content raw materials

A cotton cleaning machine and raw material technology, which is applied in the fields of fiber opening and cleaning, textile and paper making, fiber processing, etc. It can solve the problem that the manufacturer cannot change it, and the cleaning equipment has higher and higher requirements for the ability to open and remove impurities, and it is difficult to meet the use requirements. and other problems, to achieve the effect of increasing output and quality, and improving the effect of opening and removing impurities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below in conjunction with the drawings.

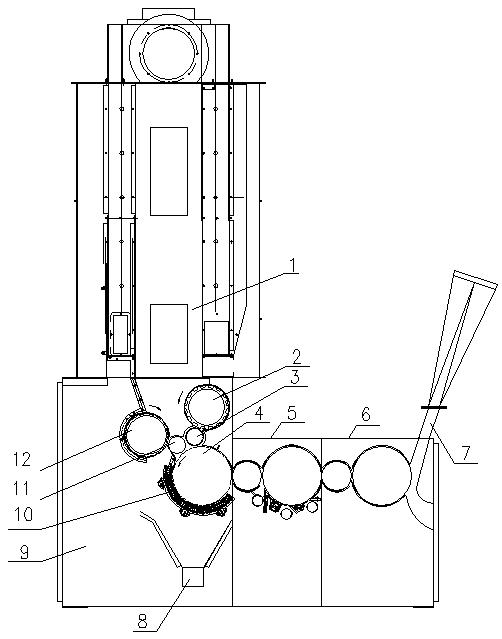

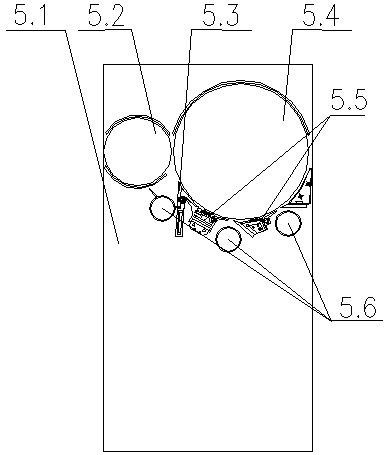

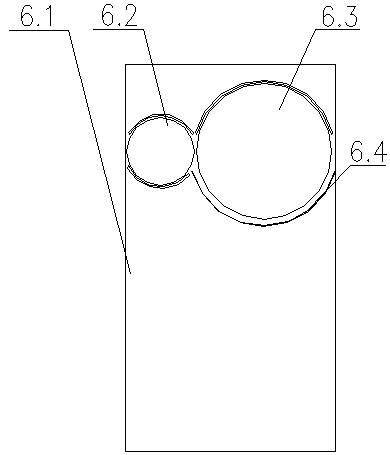

[0022] See figure 1 , The present invention is an embodiment of a cotton cleaner suitable for high-impurity raw materials, including a cotton storage box 1, a pair of cotton pressing rollers (including the first cotton pressing roller 2 and The second cotton pressing roller 12), a pair of cotton feeding rollers (including the first cotton feeding roller 3 and the second cotton feeding roller 11), the initial opening roller 4 and the initial auxiliary opening and cleaning device. At least one opening module is provided on one side of the initial opening roller 4, and the opening module includes a wall board, a transfer roller and an opening roller. The transfer roller and the opening roller are arranged on the wall board and driven by a transmission mechanism. An auxiliary opening and cleaning device is arranged around the opening roller. In the carding module that is connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com