Stink isolating method and device adopting magnetic levitation flushing and draining closing for urinal

A magnetic levitation, urinal technology, applied in water supply devices, urinals, buildings, etc., can solve the problems of poor flushing and discharging sealing performance, short life, damage, etc., and achieve good flushing and discharging sealing performance, excellent water-saving performance, and reliability. strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

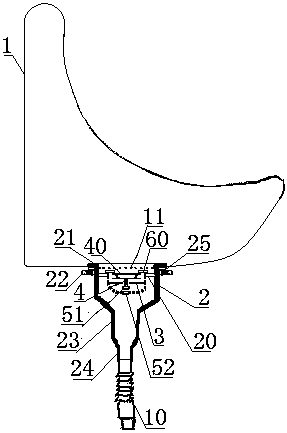

[0028] Embodiment one, such as figure 1 As shown, the urinal magnetic levitation flushing, sealing and odor isolation method and device of the present invention is that the drain of the urinal body 1 is equipped with a protective leakage plate 11 and is used to connect the drain pipe 10 or the drain to the drain. The special feature is that The 20 sealing sleeve on the upper part of the drain bucket is equipped with a magnetic levitation flushing valve. The magnetic levitation flushing valve includes an upper opening falling water cage that is matched with the outer periphery of the upper port and the inner shrinking hole 20 sealing sleeve on the upper part of the falling water bucket. The support frame 3 is vertically slidably equipped with a slide bar 4 with a closed disk 40 at the upper end. The relative position between the lower end of the slide bar 4 and the bottom of the water cage is respectively equipped with upper and lower homopolar magnets 51 and lower same pole mag...

Embodiment 2

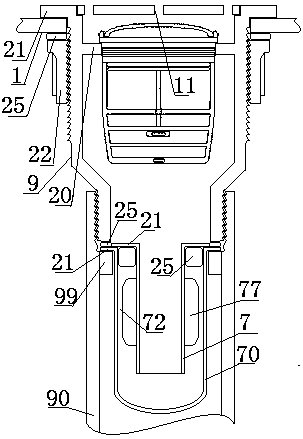

[0030] Embodiment two, such as figure 2 As shown, the difference between the device used to realize the magnetic levitation flushing and drainage sealing and odor isolation method of the urinal of the present invention and the first embodiment is that the drain bucket is not connected to the drain pipe, and the lower part of the drain bucket has a 20 sealing sleeve in the upper part with a magnetic levitation flushing and draining A water seal mechanism is arranged below the valve. The lower part of the sink is provided with a water seal core of the water seal mechanism below the upper inner shrinkage 20 sealing sleeve and the magnetic levitation flushing valve. Mouth water outlet sleeve 70, wide-mouth water outlet sleeve 70 internal interval seal fit center drain pipe 7, wide-mouth water outlet sleeve 70 is shaped on at least one water outlet 77 higher than the center drain pipe 7 lower ports. The falling water bucket is formed by connecting the upper cone bucket 9 with the...

Embodiment 3

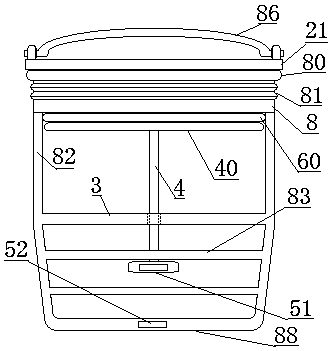

[0031] Embodiment three, such as image 3 As shown, the difference between the device used to realize the urinal magnetic levitation flushing and sealing method of the present invention and Embodiments 1 and 2 is that the drain cage is a top flange with an extended upper convex part hinged with a handle 86 on the standpipe 8 upwards. Plate 21, the outer circumference of the upper end of the standpipe 8 is arranged under the top blue plate 21 through an inner concave ring groove to configure a corrosion-resistant sealing ring 80, and the outer periphery of the standpipe 8 is formed with a threaded button 81 matched with the inner shrinkage end thread under the corrosion-resistant sealing ring 80 , the standpipe 8 is downwardly shaped with a water cage body, and the middle part of the water cage body is vertically slid with a sliding rod 4 with a closed disc 40 at the upper end through a vertical sliding support 3, and the relative position of the lower end of the slide rod 4 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com