Plugging fireproof and explosion-proof structure of valve side casing pipe of converter transformer in converter station

A technology of converter transformers and explosion-proof structures, which is applied to building components, building structures, buildings, etc., can solve the problems of fire and explosion-proof performance, electromagnetic isolation effect and sealing performance, etc., and achieve good electromagnetic isolation effect, good explosion-proof performance, Guarantees the effect of sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below with reference to the accompanying drawings and embodiments, and the mode of the present invention includes but not limited to the following embodiments.

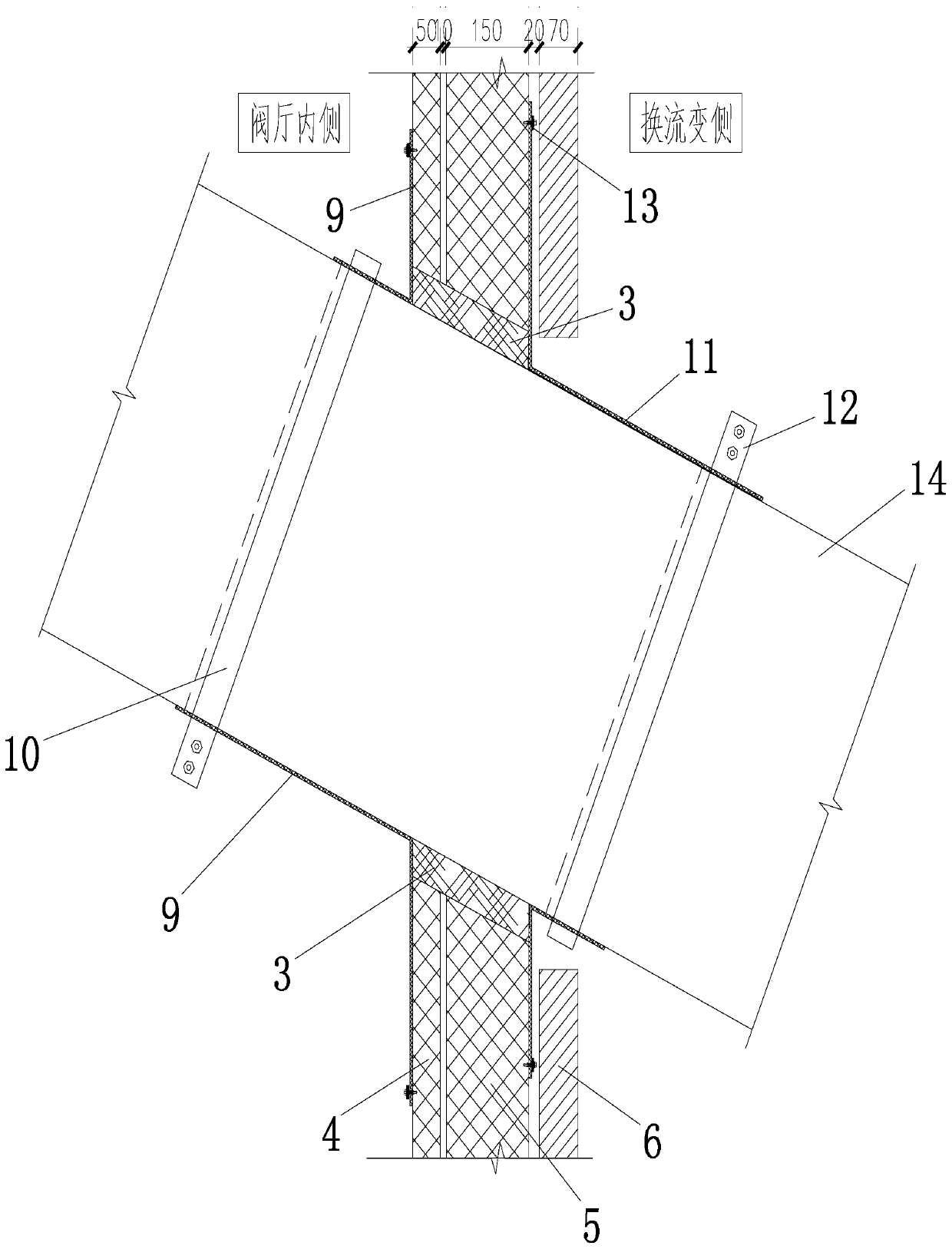

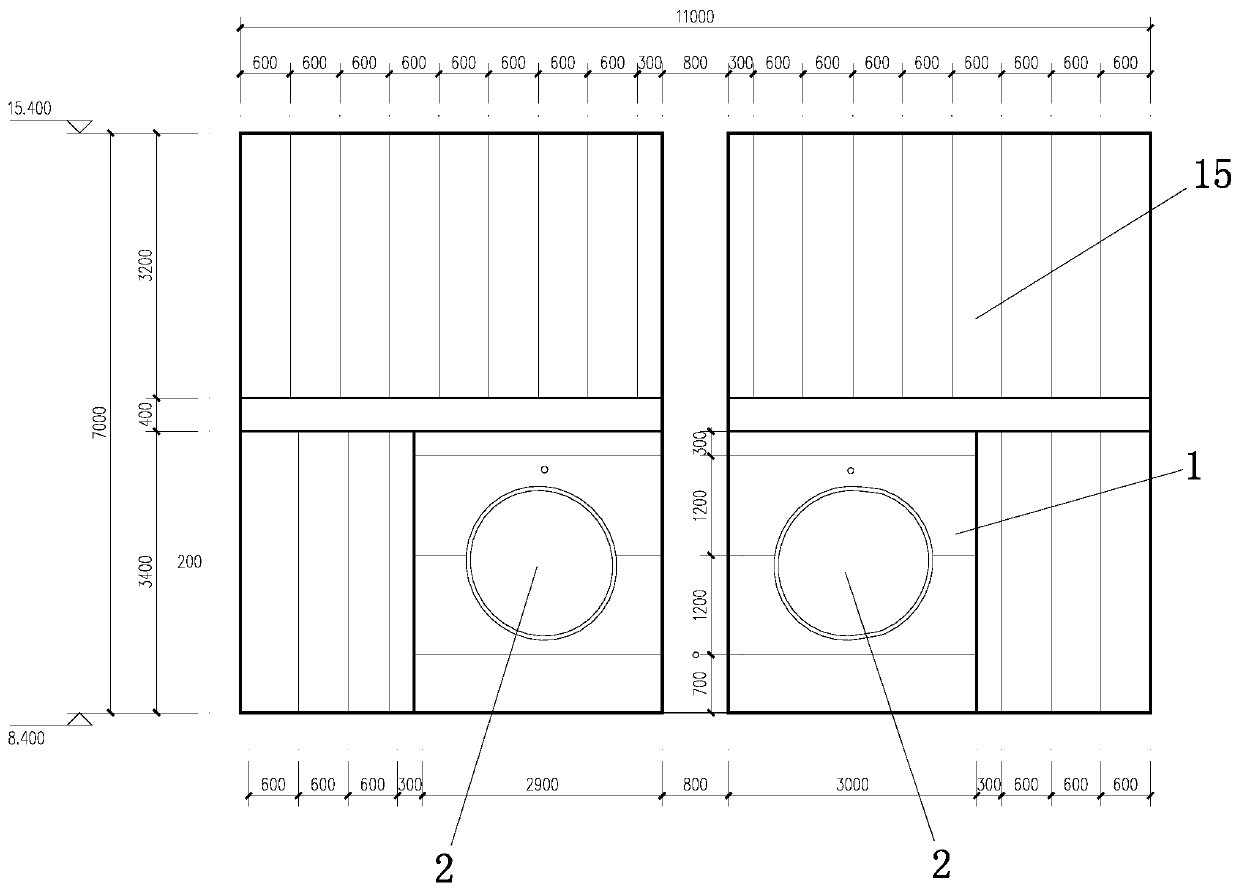

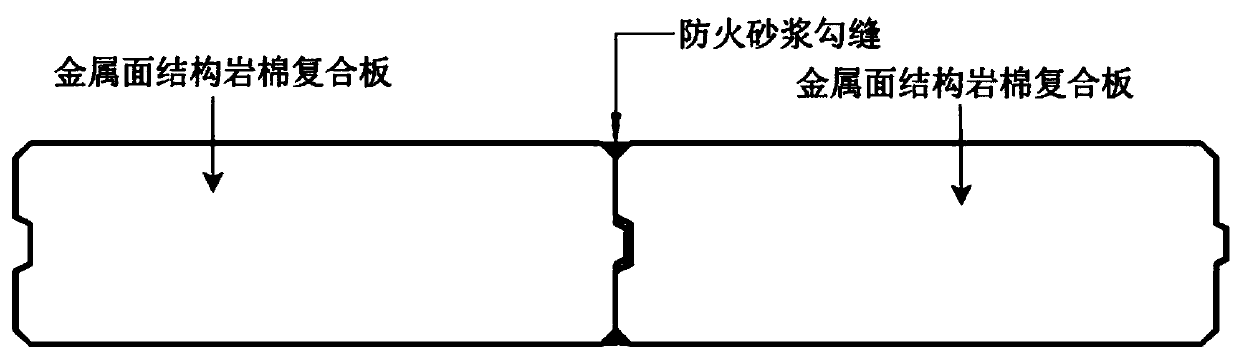

[0028] Such as Figure 1-4As shown, the present invention provides a fire-proof and explosion-proof structure for the plugging of the converter transformer valve side bushing in the converter station, which has a simple structure, scientific and reasonable design, and is easy to use. Well, the sealing performance is ideal. The present invention includes a fireproof and explosion-proof plate 1 sealed and installed on the fireproof wall 15 of the valve hall of the power station. The center of the fireproof and explosion-proof plate 1 is provided with a converter bushing installation hole 2 that matches the converter bushing 14. The installation holes 2 of the converter bushing are distributed obliquely, and the inclination thereof is consistent with the gradient of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com