Battery pack equalization module, system and control method based on bidirectional flyback converter

A flyback converter, battery module technology, applied in battery/fuel cell control devices, charge balancing circuits, battery load switching, etc. The effect of reducing the volume, improving the equalization efficiency, and increasing the equalization speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] A battery pack balancing module based on a bidirectional flyback converter in this embodiment includes:

[0043] A bidirectional flyback converter, the primary side of the bidirectional flyback converter is connected in series with the first battery module through the first switch tube, and the secondary side of the bidirectional flyback converter is connected in series with the second battery module through the second switch tube connected; the first battery module comprises a plurality of battery cells connected in series;

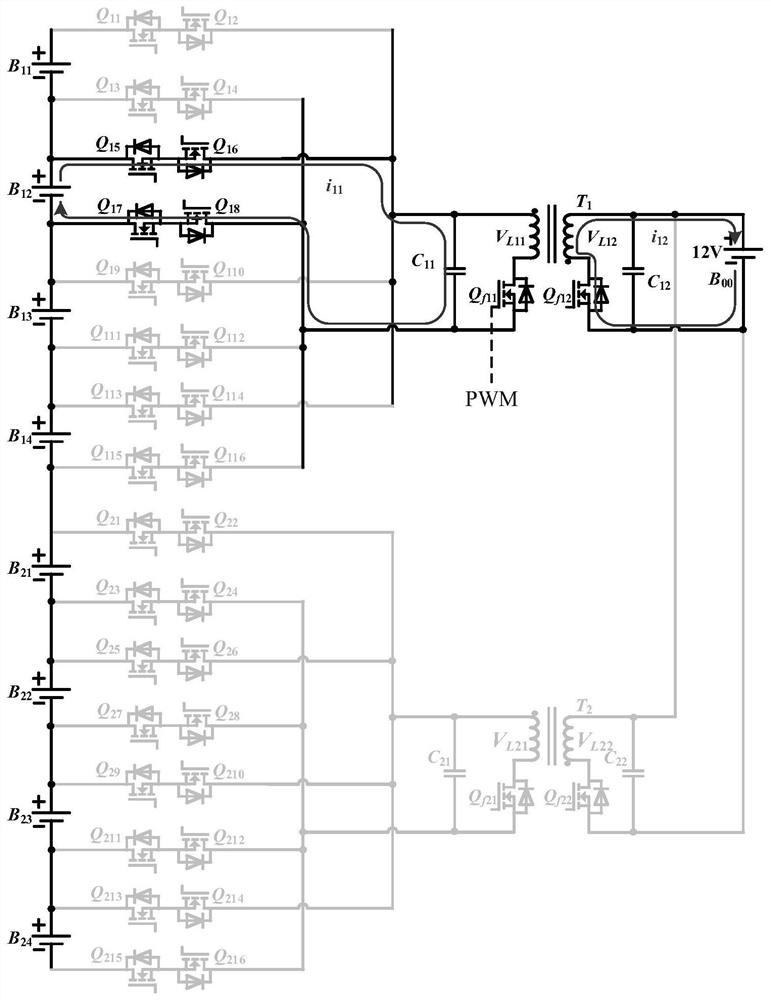

[0044] Both ends of each battery cell are connected to the two ends of the primary side of the bidirectional flyback converter through the reverse series connection of the third switch tube and the fourth switch tube; the first switch tube, the second switch tube, the third switch and the The fourth switching tubes are all connected to a microcontroller, and the microcontroller is used to compare the voltage of each battery cell with the average v...

Embodiment 2

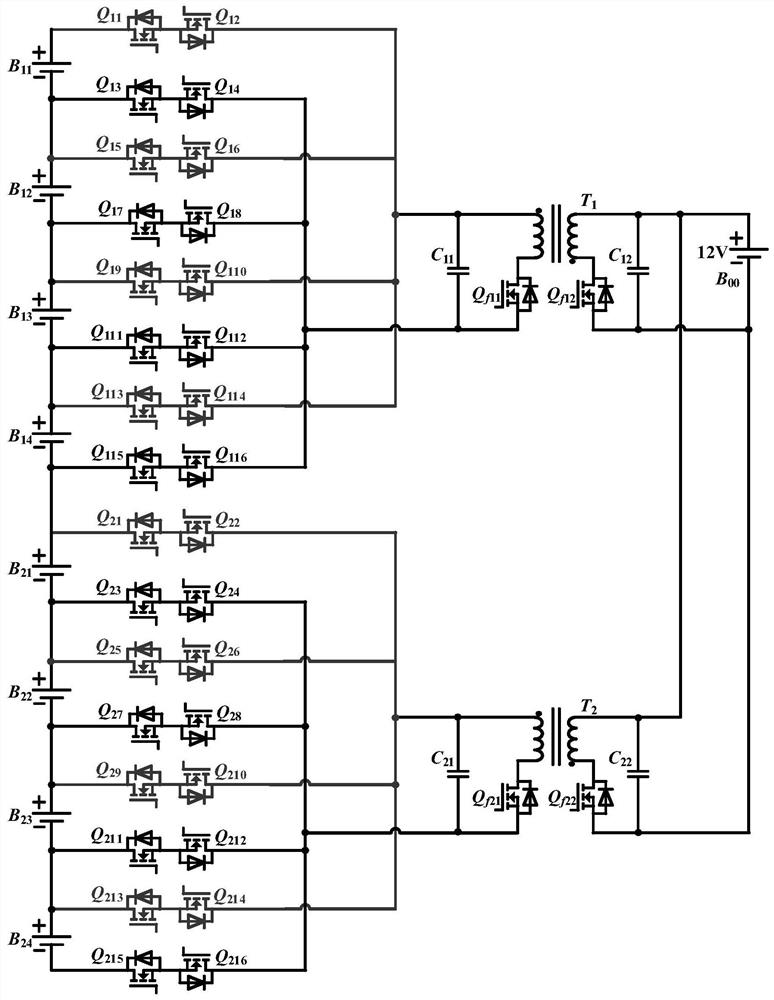

[0074] This embodiment provides a battery pack equalization modular system based on a bidirectional flyback converter, which controls the opening and closing of the primary and secondary side MOS transistors of the bidirectional flyback converter through PWM control signals, and can realize any section of any module. The equalization of the combination of adjacent battery cells to any section of adjacent battery cells in any module greatly improves the equalization efficiency and speed.

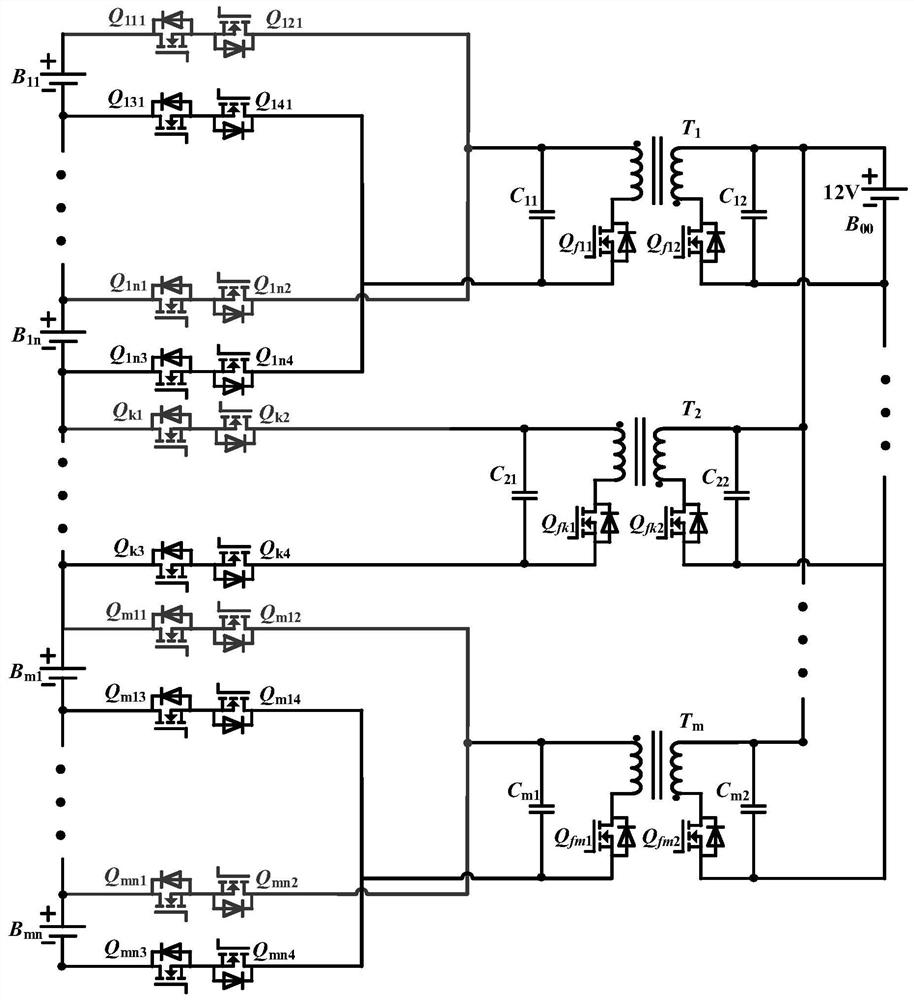

[0075] like figure 1 As shown, a battery pack balancing modular system based on a bidirectional flyback converter in this embodiment includes:

[0076] m battery pack equalization modules, each battery pack equalization module includes a bidirectional flyback converter, the primary side of the bidirectional flyback converter is connected in series with the first battery module through a first switch tube, and the bidirectional flyback converter The secondary side of the second battery module...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com