Solenoid valve type ejector driving circuit system

A technology for driving circuits and injectors, applied in charging systems, machines/engines, fuel injection devices, etc., can solve the problems of complex circuits, high requirements for injector manufacturing processes, and large heat generation of injectors, so as to reduce driving power. , The effect of maintaining normal opening time and reducing heat generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

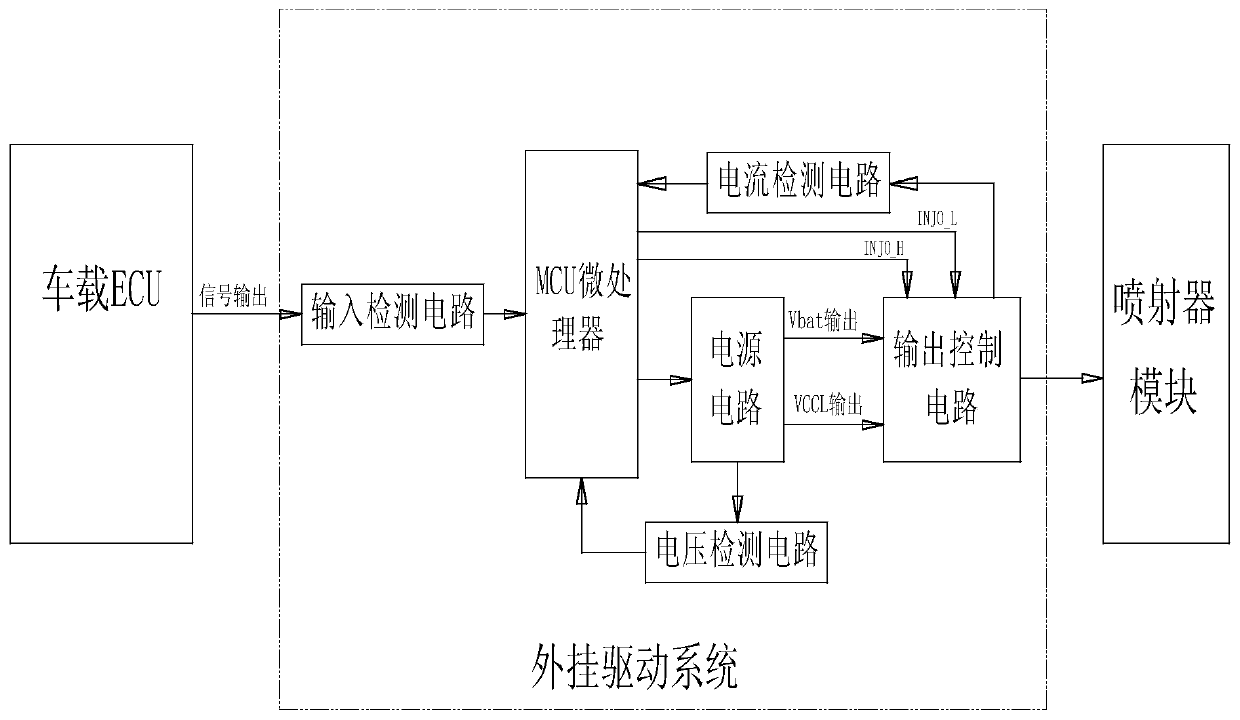

[0054] A solenoid valve injector driving circuit system (see figure 1 ), including a vehicle-mounted ECU, an injector module, and a plug-in drive system, and the plug-in drive system includes an input detection circuit, an MCU microprocessor, a power supply circuit, an output control circuit, a voltage detection circuit, and a current detection circuit, wherein:

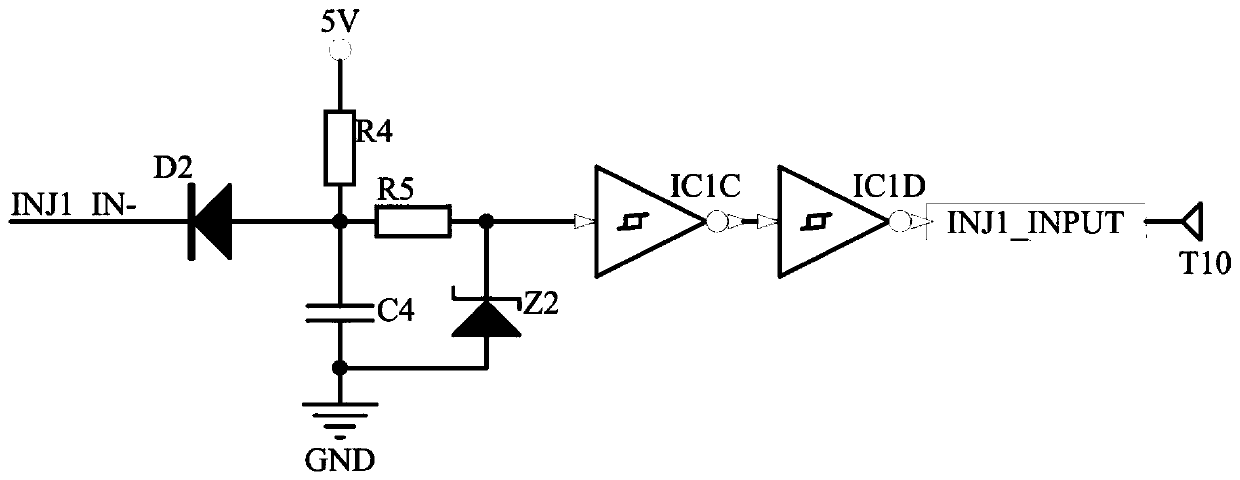

[0055] The input detection circuit is used to detect the input signal of the injector module, the input end of the input detection circuit is connected with the output end of the vehicle-mounted ECU, and the output end of the input detection circuit is connected with the input end of the MCU microprocessor;

[0056] Described MCU microprocessor is as control core, is responsible for the control of each module, and the output end of this MCU microprocessor is connected with the input end of power supply circuit, output control circuit respectively;

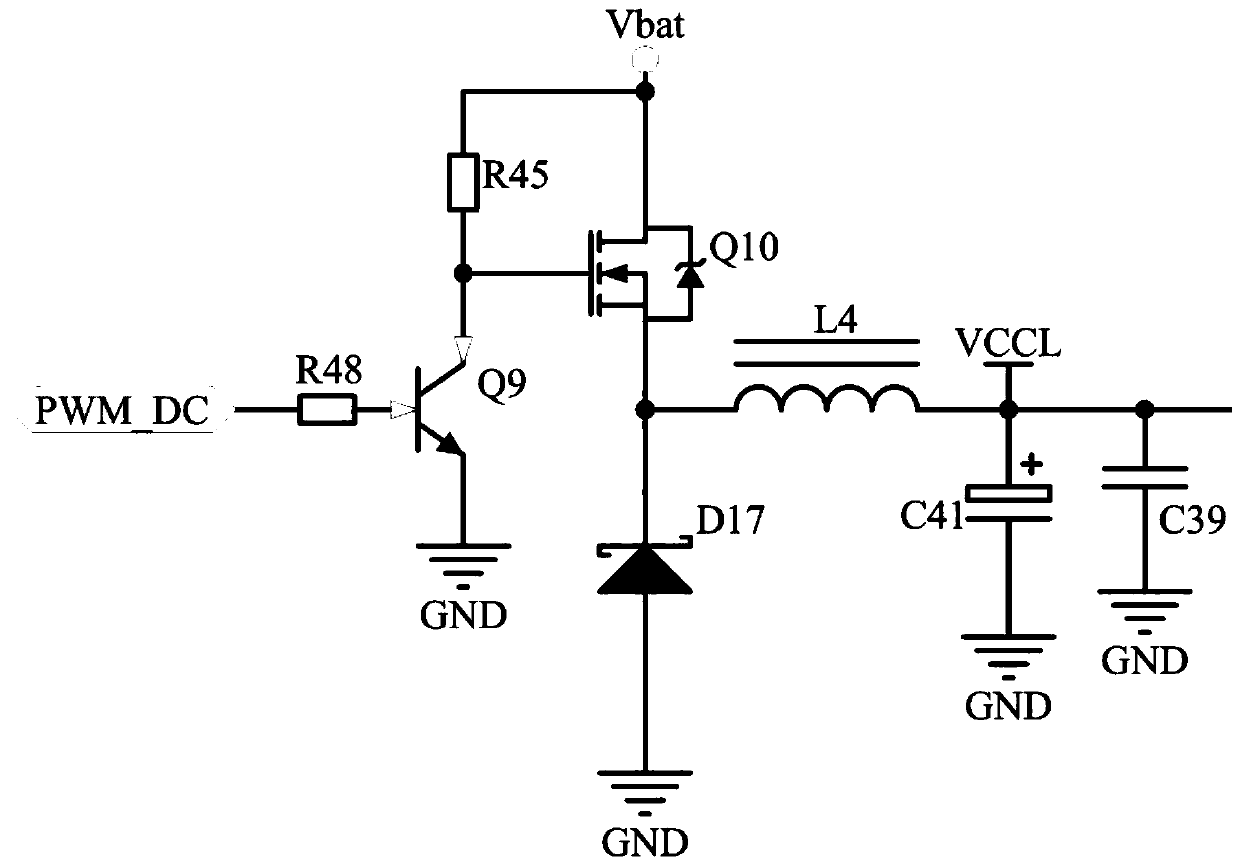

[0057] The power supply circuit is used to provide Vbat voltage or V...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com