Constant-rate exhaust gas treatment system

A flow treatment system and exhaust gas technology, applied in the pipeline system, control/regulation system, flow control, etc., can solve the problems of high equipment cost, increased operation and maintenance costs, and high waste gas treatment costs, and achieve the effect of avoiding negative pressure backflow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

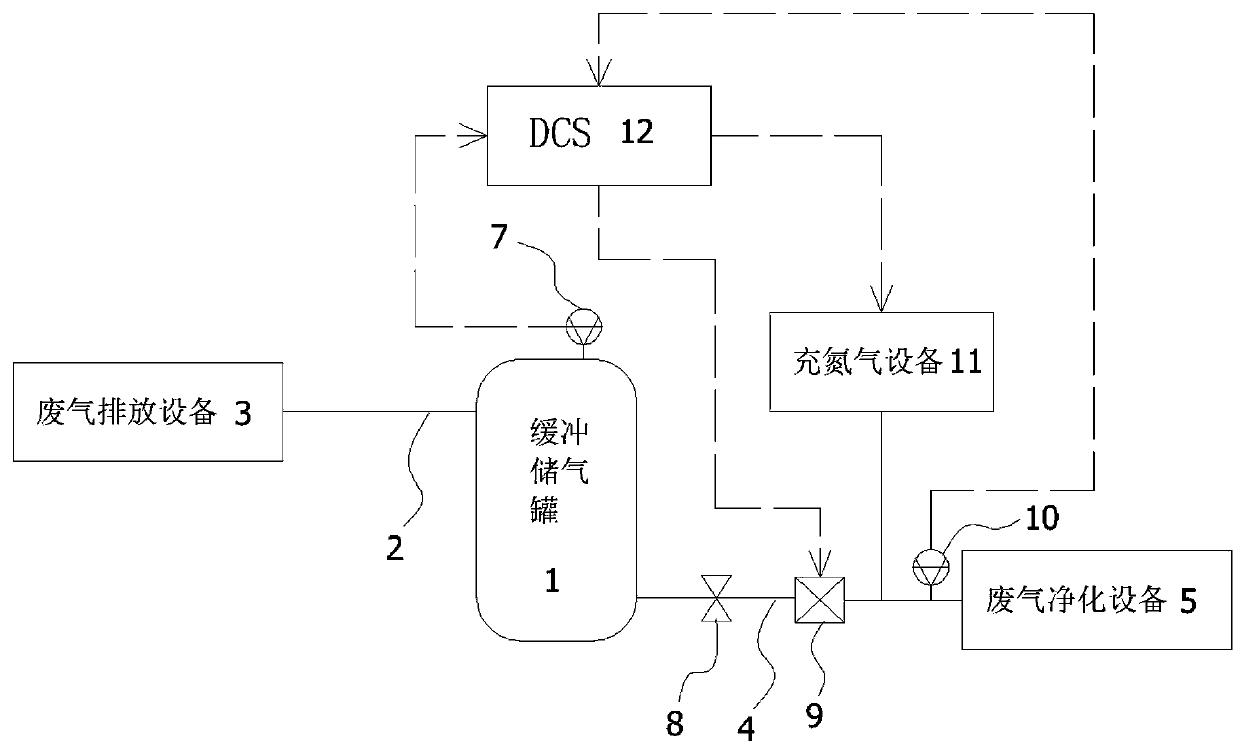

[0017] Such as figure 1 As shown, the present invention provides a constant flow treatment system for exhaust gas, including a buffer gas storage tank 1, the inlet of the buffer gas storage tank 1 is connected to the exhaust gas discharge device 3 through the intake pipe 2, and the outlet of the buffer gas storage tank 1 is connected through the outlet pipe 4 Exhaust gas purification equipment 5; a first vacuum gauge 7 is provided on the top of the buffer gas storage tank 1; a shut-off valve 8, a vacuum pump 9 and a second vacuum gauge 10 are arranged in the pipeline of the gas outlet pipe 4 along the gas outlet direction; the vacuum pump 9 and the second vacuum gauge The pipeline between gauges 10 is also connected with nitrogen charging equipment 11.

[0018] The constant current processing system also includes a DCS12, the first vacuum gauge 7 and the second vacuum gauge 10 are connected to the input interface of the DCS12, and the output interface of the DCS12 is connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com