Oscilloscope assembling probe

An oscilloscope and plug technology, which is applied in the field of oscilloscope assembly probes, can solve the problems of cumbersome and time-consuming, objects scratched by wires, scattered wires, etc., and achieve the effect of improving user comfort, increasing installation speed, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

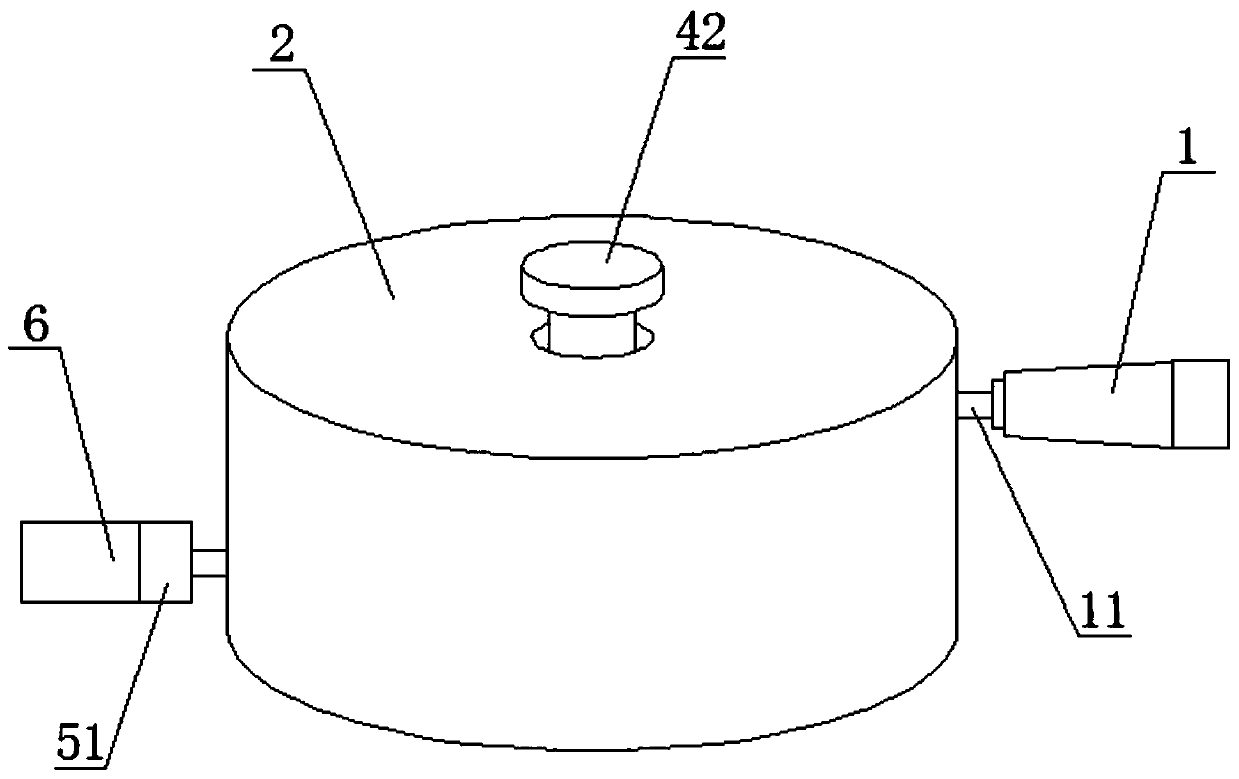

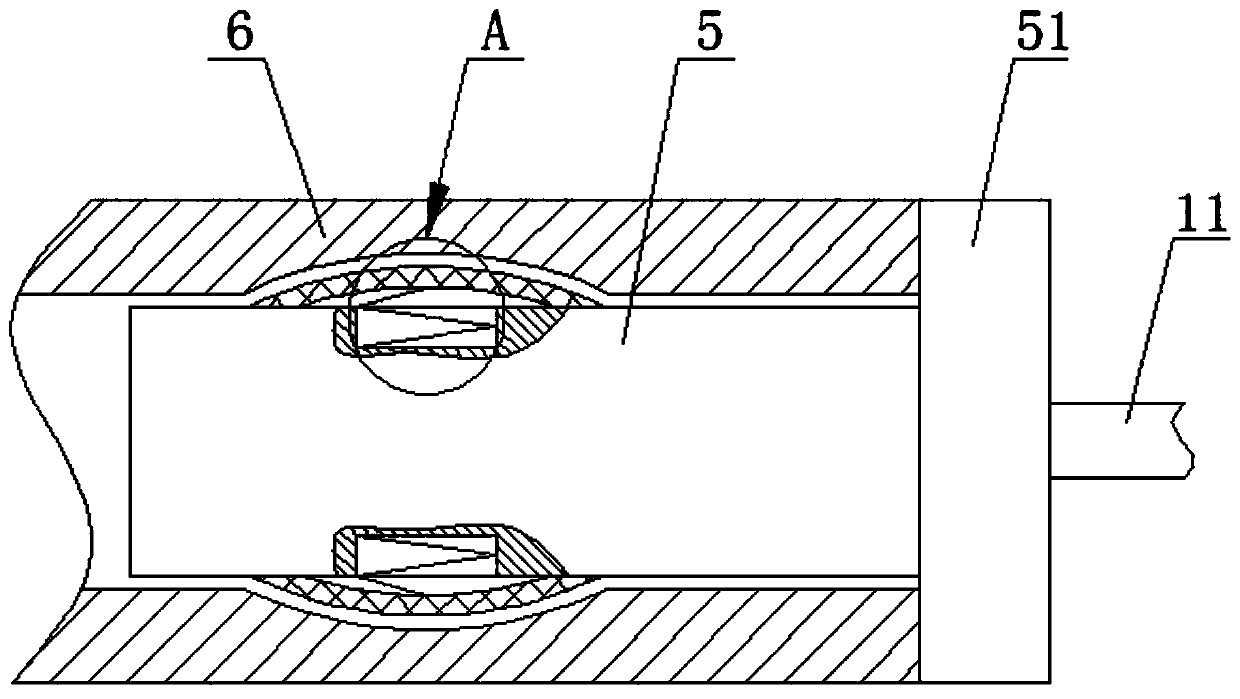

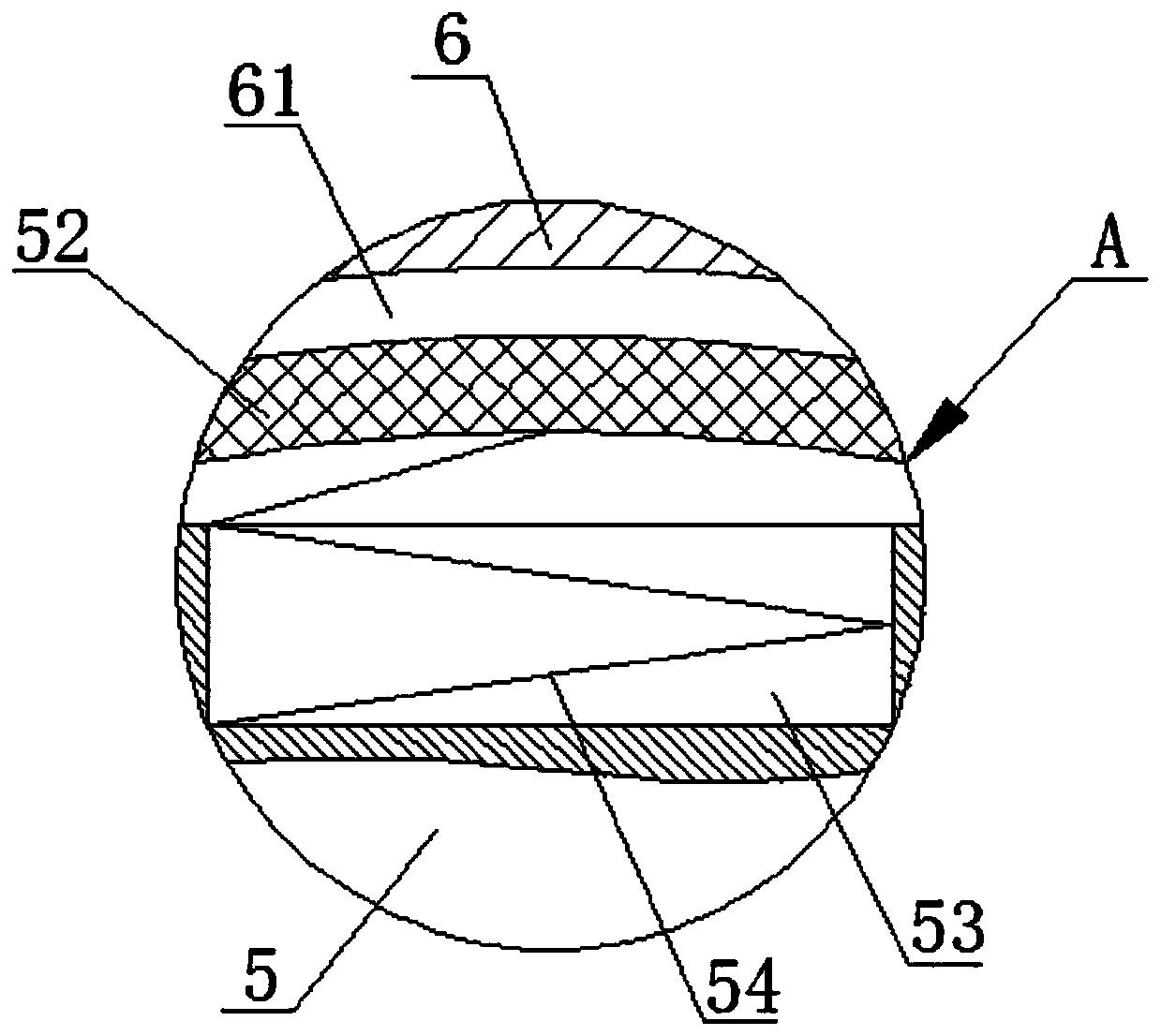

[0035] see Figure 1-5 , an oscilloscope assembly probe, including the probe housing 1, see Figure 1-5 , the left end of the probe housing 1 is fixedly connected with a wire 11, the surface of the wire 11 is slidingly sleeved with a storage box 2, the storage box 2 is used to store the excess length of the wire 11, the storage box 2 is provided with a groove 21, and the storage box 2 is set There are symmetrical clamping holes 22. When the clamping rod 41 is clamped into the clamping hole 22, the reel 3 stops rotating. The storage box 2 is provided with symmetrical through holes 23. The symmetrical through holes 23 are used to pass both ends of the wire 11. , the storage box 2 is rotated and sleeved with a reel 3, and the reel 3 is provided with a mounting groove 33, and a coil spring 34 is fixedly connected in the mounting groove 33, and the coil spring 34 is squeezed when the reel 3 rotates Form resilience, after the reel 3 loses the fixation of clamp bar 41, the resilienc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com