Universal pigmentary preparations for colouring and reenforcing plastics

A pigment preparation and pigment technology, applied in the direction of pigment slurry, coating, etc., can solve the problem of not allowing organic pigment concentrates, etc., and achieve the effects of excellent grinding and deagglomeration, excellent homogenization and dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

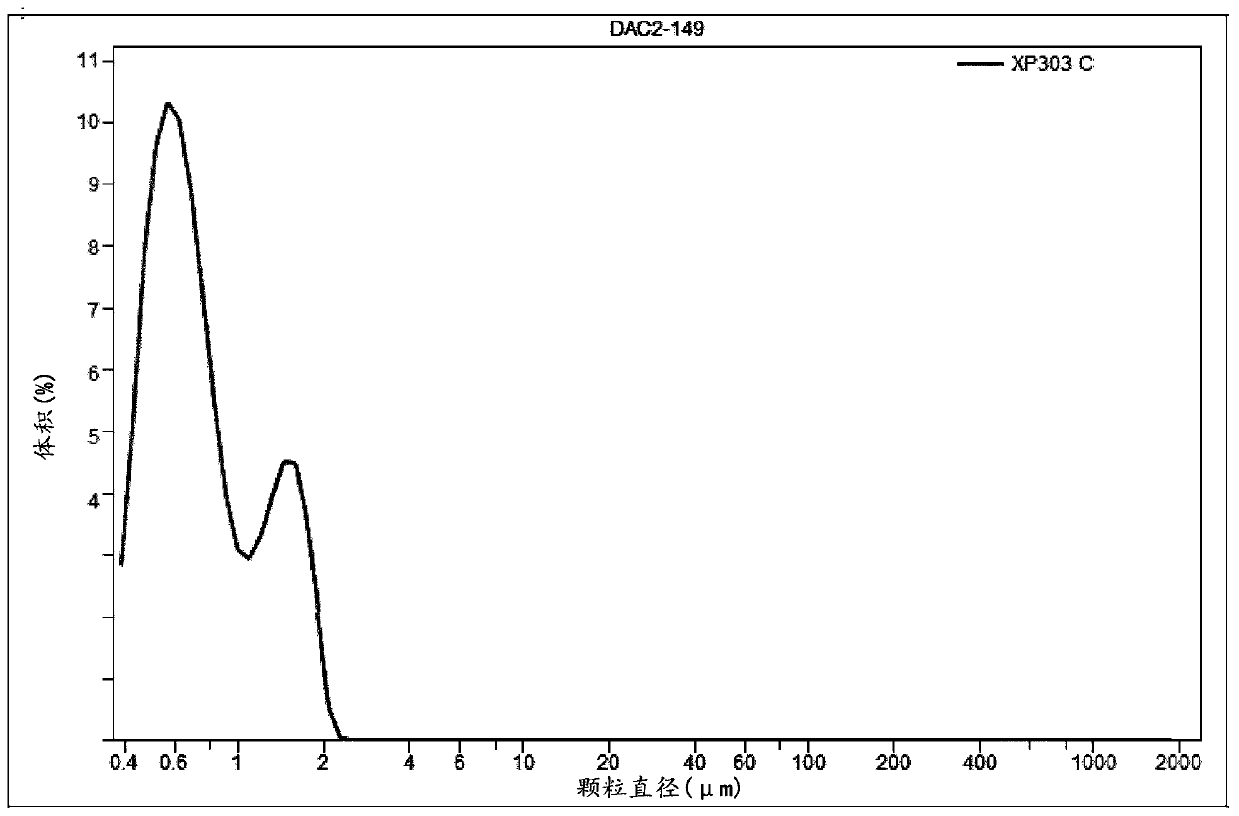

[0140] Preparation of Pigment Preparation XP303-C (Pigment Concentration = 85%)

[0141] 6800 g of Pigment Red 254 pigment (available as SR2P from Cinic company) was mixed with 1,200 g of dispersant Disperplast 1018 (supplied by BYK company) and ground.

[0142] The dry grinding unit is a discontinuous unit equipped with 4 rotors.

[0143] Process parameters: 1 minute at a peripheral speed of 6 m / s, 14 minutes at a peripheral speed of 15 m / s and then 6 minutes at a peripheral speed of 25 m / s; the temperature reaches 72°C.

[0144] The pigment preparations thus obtained correspond to microgranules.

[0145] The particle size values of the pigment additives in the pigment preparation are as follows (analyzed in butyl acetate dispersion with the aid of a laser Beckman Coulter particle size analyzer):

[0146] D10 = 0.571 μm

[0147] D50=0.790μm

[0148] D90=1.034μm

[0149] The particle size of the microparticles: in the range of 80-350 μm.

Embodiment 2

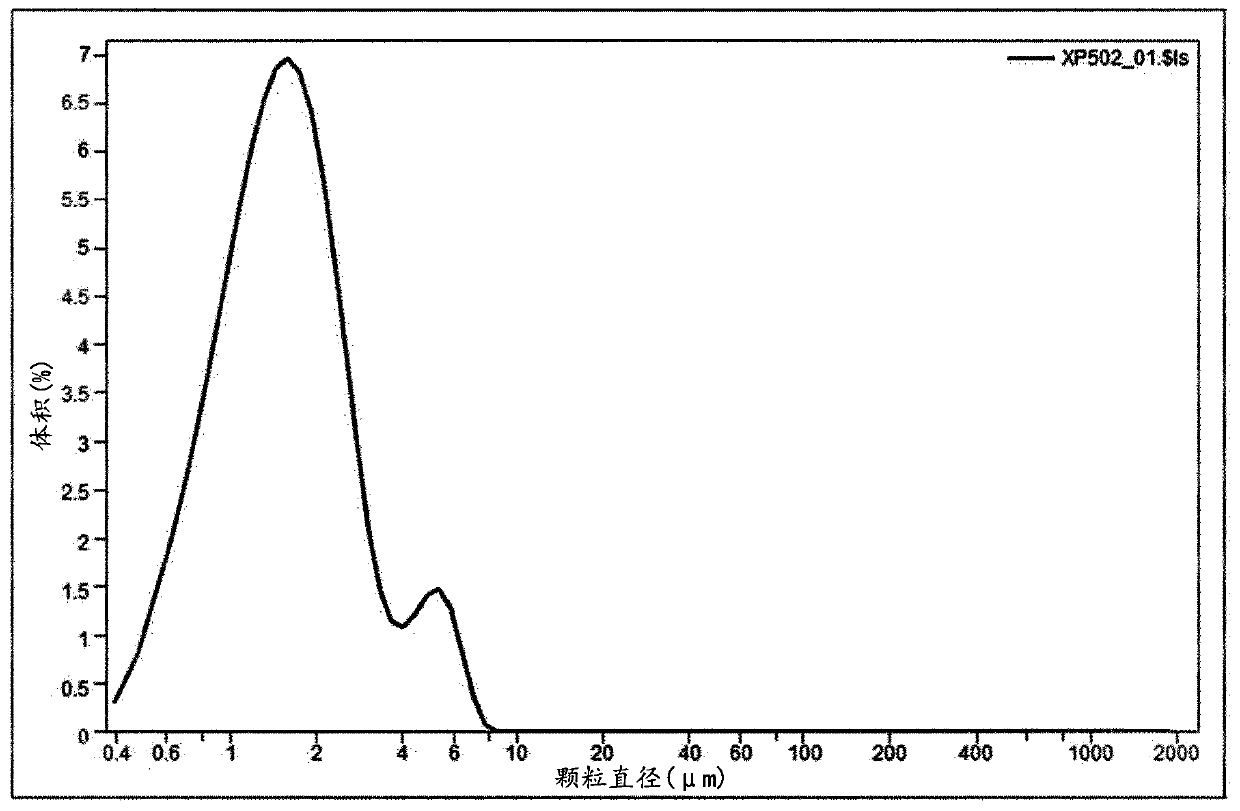

[0151] Preparation of Pigment Preparation XP901 (Pigment Concentration = 80%)

[0152] 6400 g of carbon black pigment PBL-7 (Carbon Black Special Black 100 from the company Orion) were mixed with 1600 g of dispersant Disperplast 1018 (by BYK.) and ground by means of a discontinuous dry mill equipped with 4 rotors. Process parameters: 1 minute at a peripheral speed of 6 m / s, 14 minutes at a peripheral speed of 15 m / s and then 6 minutes at a peripheral speed of 25 m / s; the temperature reaches 132°C. The composition obtained is in the form of dust-free granules.

[0153] D50 of the pigment additive in the pigment preparation (measured as in Example 1) = 1.5 μm

[0154] The particle size of the microparticles: 80-350 μm

Embodiment 3

[0156] Preparation of Pigment Preparation XP307C (Pigment Concentration = 90%)

[0157] 5400 g of Pigment Red 101 pigment (Bayferrox 130M from Lanxess) and 600 g of dispersant Disperplast 1018 (by BYK) were mixed and ground by means of a discontinuous dry mill equipped with 4 rotors.

[0158] Process parameters: 1 minute at a peripheral speed of 6 m / s, 14 minutes at a peripheral speed of 25 m / s. The temperature reaches 50°C.

[0159] The composition obtained has the form of a free-flowing powder.

[0160] D50 of the pigment additive in the pigment preparation (measured as in Example 1) = 1.2 μm

[0161] The particle size of the powder is <50μm

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com