Polymer memory rubber tire cold patch and production equipment and production technology thereof

A rubber tire and production process technology, applied in the field of polymer memory rubber tire cold patch and its production equipment and production process, can solve the problems of air leakage points that cannot fully cover the carcass, frequent secondary air leakage, and easy Problems such as tangent shift occur, to achieve the effect of saving material cost, shortening the time used, and simple, convenient and fast operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

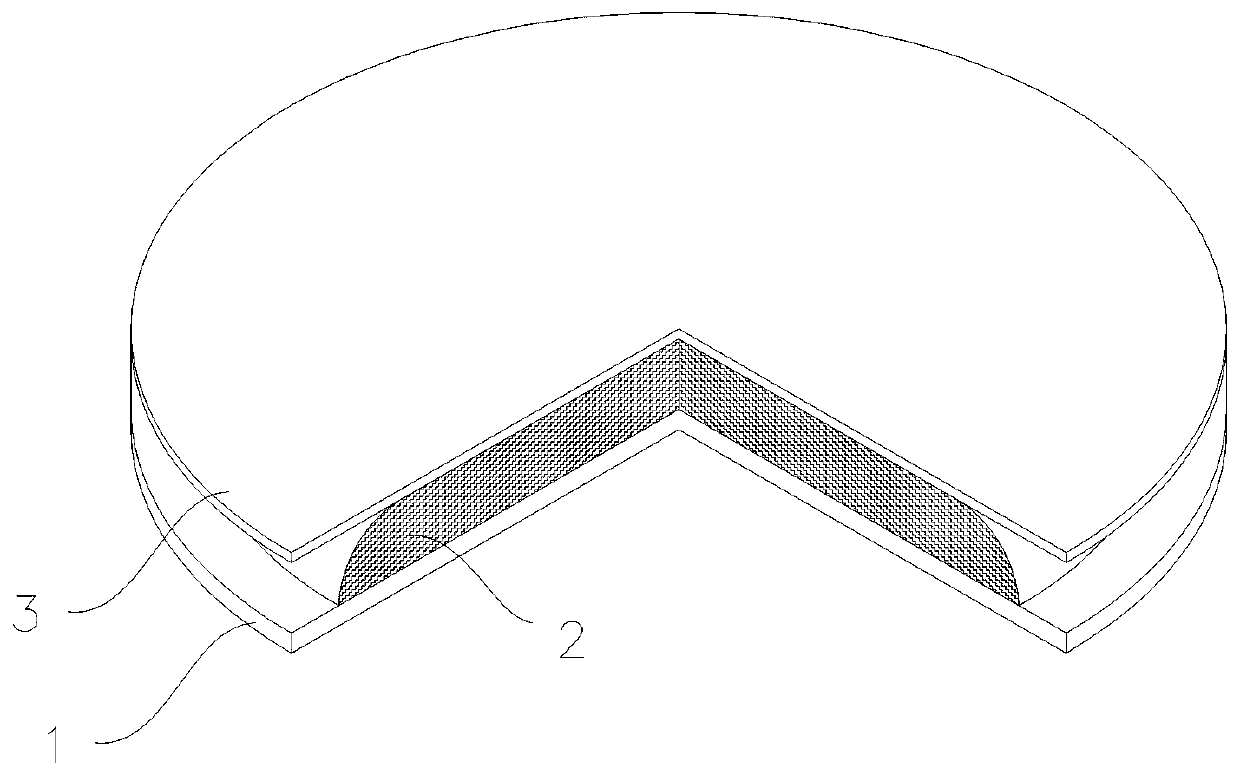

[0108] Such as figure 1 , 2 , Shown in 3, a kind of polymer memory rubber tire cold patch described in the present embodiment, hereinafter all be referred to as polymer patch for short, is characterized in that:

[0109] The polymer patch includes a base layer, a rubber layer, and a release paper layer;

[0110] The base layer is made of high temperature resistant cloth or aluminum foil;

[0111] The rubber layer is made of polymer memory rubber material with shape memory function;

[0112] The release paper layer is made of release paper;

[0113] The base layer is circular or oval or rounded rectangular, located at the bottom of the polymer patch, and plays the role of carrying the patch;

[0114] The rubber layer is tiled on the base layer, and the edge of the rubber layer is spaced from the edge of the base layer;

[0115] The release paper layer covers the top of the rubber layer, and the release paper layer has the same shape and size as the base layer;

[0116] Th...

Embodiment 2

[0144] [Example 2] How to use

[0145] The using method of described polymer patch comprises the following steps, is characterized in that:

[0146] SA1, separate the tire from the wheel hub;

[0147] SA 2. Locate the leak point and clean the tread around the leak point;

[0148] SA 3. Paste the polymer patch on the air leakage point of the tire carcass.

[0149] In the SA3 step of the method for using the polymer patch, the method for using the polymer patch includes:

[0150] SA 3-1. Remove the release paper layer of the polymer patch;

[0151] SA3-2, facing the rubber layer of the polymer patch towards the tire carcass to be repaired;

[0152] If the tire is a tubeless tire, the rubber layer faces the inner wall of the tubeless tire;

[0153] If the tire is a tire with an inner and outer tire structure, the rubber layer faces the outer wall of the inner tire;

[0154] Make the central position of the rubber layer correspond to the central position of the tire leak poi...

Embodiment 3

[0159] [Example 3] production equipment

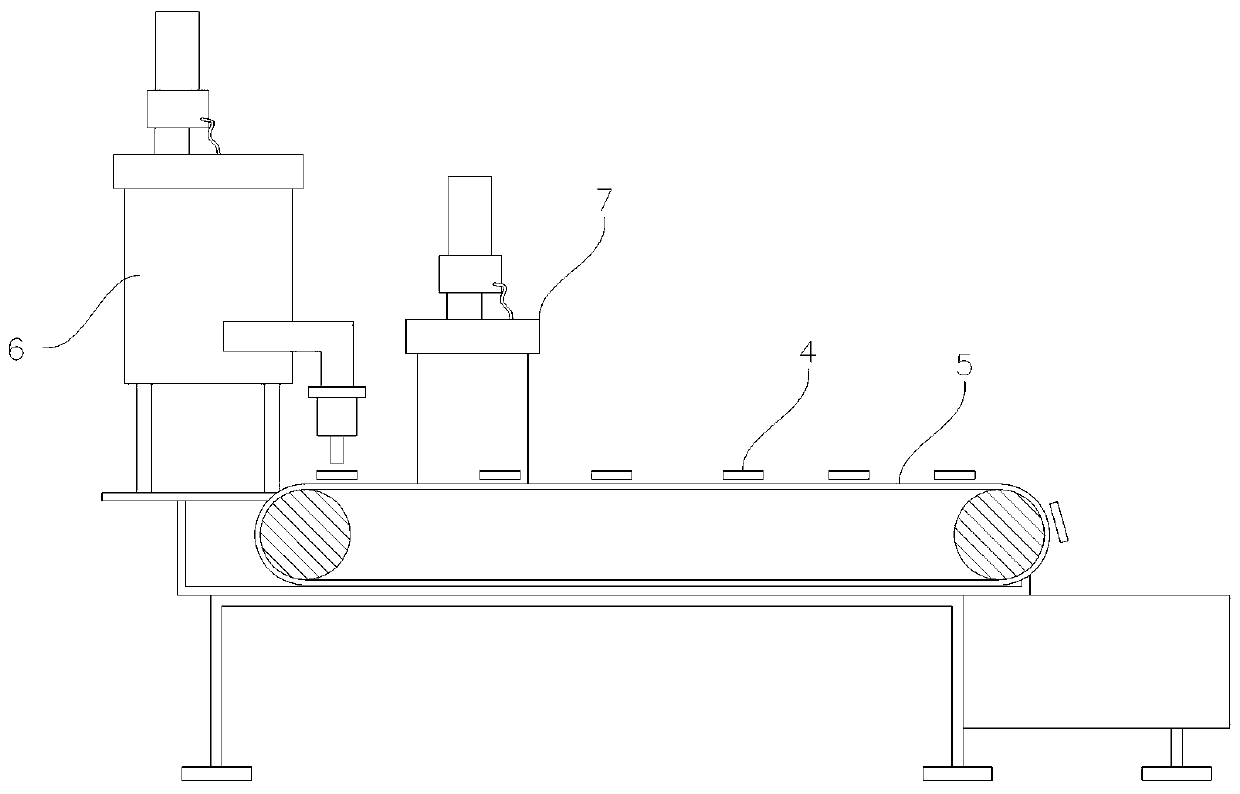

[0160] The production equipment for manufacturing the polymer patch includes the following devices, characterized in that:

[0161] The glue injection machine is used to mix and prepare the raw materials for preparing polymer memory rubber to prepare polymer memory rubber and pretreat the prepared polymer memory rubber, or use the glue injection machine to directly inject polymer memory rubber Perform pretreatment; the glue injection machine outputs the pretreated polymer memory rubber to manufacture the polymer patch;

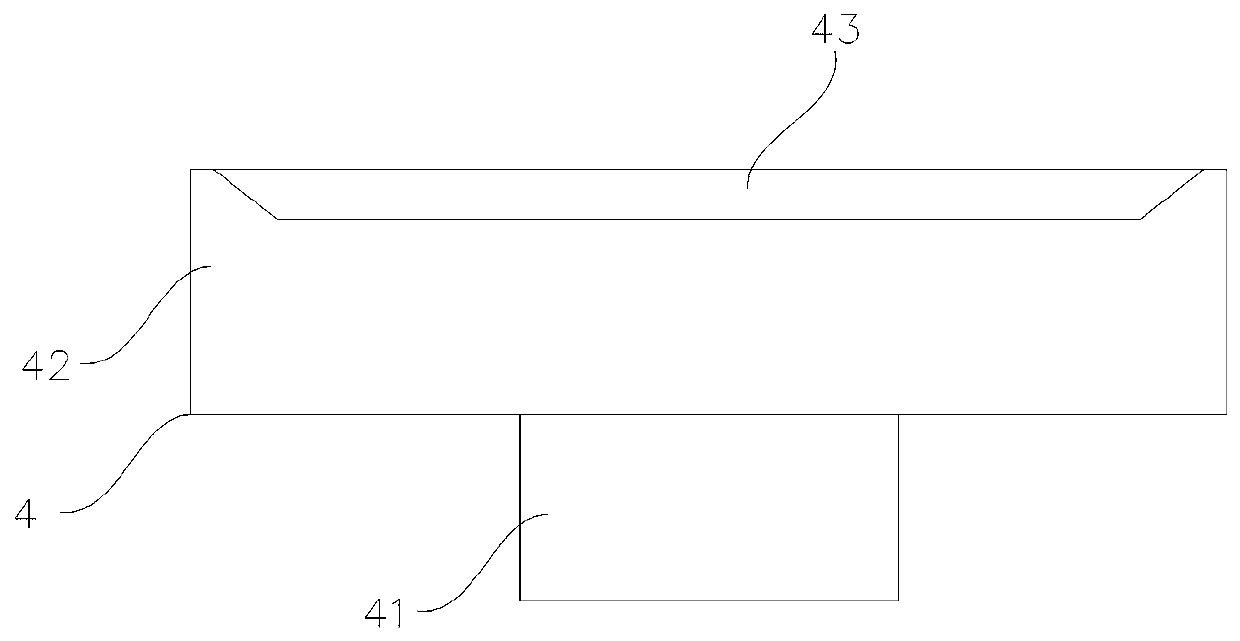

[0162] A shaping mold, used to receive the polymer memory rubber output by the glue injection machine, and make the polymer memory rubber heat and shape, cool and shape;

[0163] A high-frequency heater is used to reheat the shaping mold and the polymer memory rubber on the shaping mold;

[0164] The conveying device is used to connect the glue injection machine and the shaping mold, and realize the transfer of mater...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com