Optical coating multi-angle umbrella frame and coating machine comprising same

An optical coating, multi-angle technology, used in optics, optical components, sputtering, etc., can solve the problems of inability to cover evaporation materials, increase coating costs, film defects or film deviation defects, and improve the coating yield. , The coating quality is stable, and the effect of reducing the film deficiency or film deviation defect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

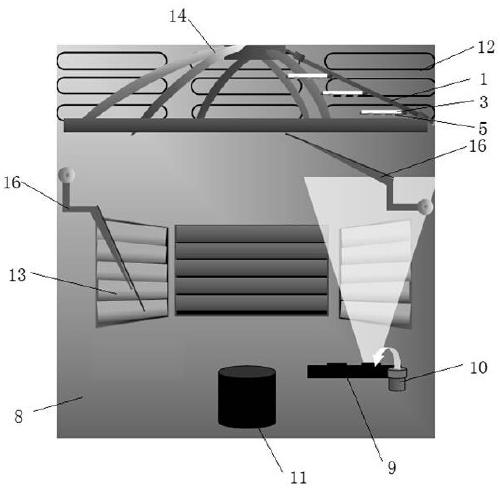

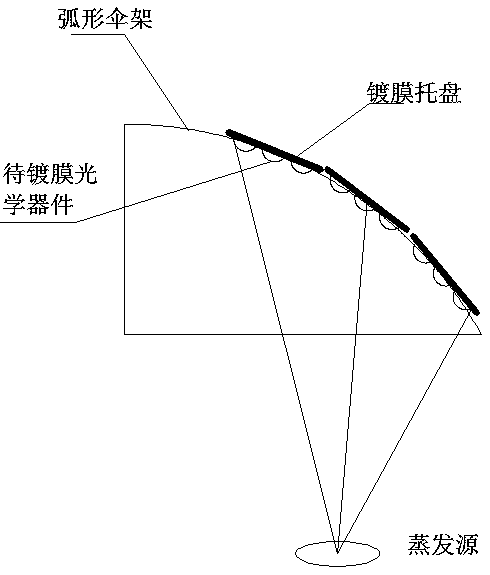

Embodiment approach 1

[0032] This embodiment provides an optical coating multi-angle umbrella stand, such as Figure 7 and 8 As shown, it is mainly composed of several fan-shaped umbrella pieces, and the circumference of several umbrella pieces is fixed on the umbrella ribs to form an umbrella frame 14 with an umbrella structure. Each umbrella piece is composed of a fan-shaped bracket 1 and four support plates 3 with different widths. According to the shape of the fan-shaped bracket 1, four support plates 3 are arranged on the support 1 sequentially from top to bottom, and one end of the four support plates 3 is respectively rotated and connected to the same side of the support 1, and the connection between each support plate 3 and the support 1 The included angles are respectively fixed by an angle limit mechanism 4, and the other end is a free end; Figure 9 As shown, the above-mentioned angle limiting mechanism 4 is a limiting block 401 with a supporting inclined surface, the limiting block 401...

Embodiment approach 2

[0037] This embodiment is a further improvement of Embodiment 1. The main improvement is that in Embodiment 1, if the surface of the optical device 5 to be coated is regular and does not have an over-convex or over-concave shape, in general, each support plate 3 Adjusting to be parallel to the horizontal plane can ensure that the surface to be coated of the optical device 5 to be coated on it is directly facing the evaporation source below; For film deficiency, film deficiency or film partial defect, it is necessary to adjust the angle θ between each support plate 3 and the support 1 so that the surface to be coated of the optical device 5 to be coated faces the evaporation source to effectively avoid the above evaporation defects. In Embodiment 1, once the angle θ between the bracket 1 and the support plate 3 is fixed by the angle limiting mechanism 4, it cannot be changed. If you want to change it, you can only replace the angle limiting mechanism 4 of the required angle, tha...

Embodiment approach 3

[0042] This embodiment is a further improvement of Embodiment 1, the main improvement is that in this embodiment, as Figure 9 , the height of each support plate 3 is equal, and on each support 1, the spacing between each support plate 3 is equal to the height of each support plate 3, and the free end of each support plate 3 is fixed and folded. The limit block 401 of the angle limit mechanism 4 is provided with a folding positioning slot 7 that is fixed with the folding positioning tenon 6 and buckled in the table below. When it is necessary to adjust the angle θ between each support plate 3 and the bracket 1 to 0 ° and fixed, each support plate 3 is rotated to overlap with the bracket 1 along the rotating connection axis with the limit block 401, and the folding positioning tenon 6 at the end of the lower support plate 3 is buckled and fixed to the upper support plate 3 In the folding positioning slot 7 in the angle limiting mechanism 4, the angle θ between each support plat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| cover factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com