Auxiliary device based on application of reducing mold of horizontal annular knitting machine

An auxiliary device and weaving machine technology, which is applied in the direction of braided fabrics, textiles, and papermaking, can solve the problems of multi-diameter molds and high mold costs, and achieve the effect of fast connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

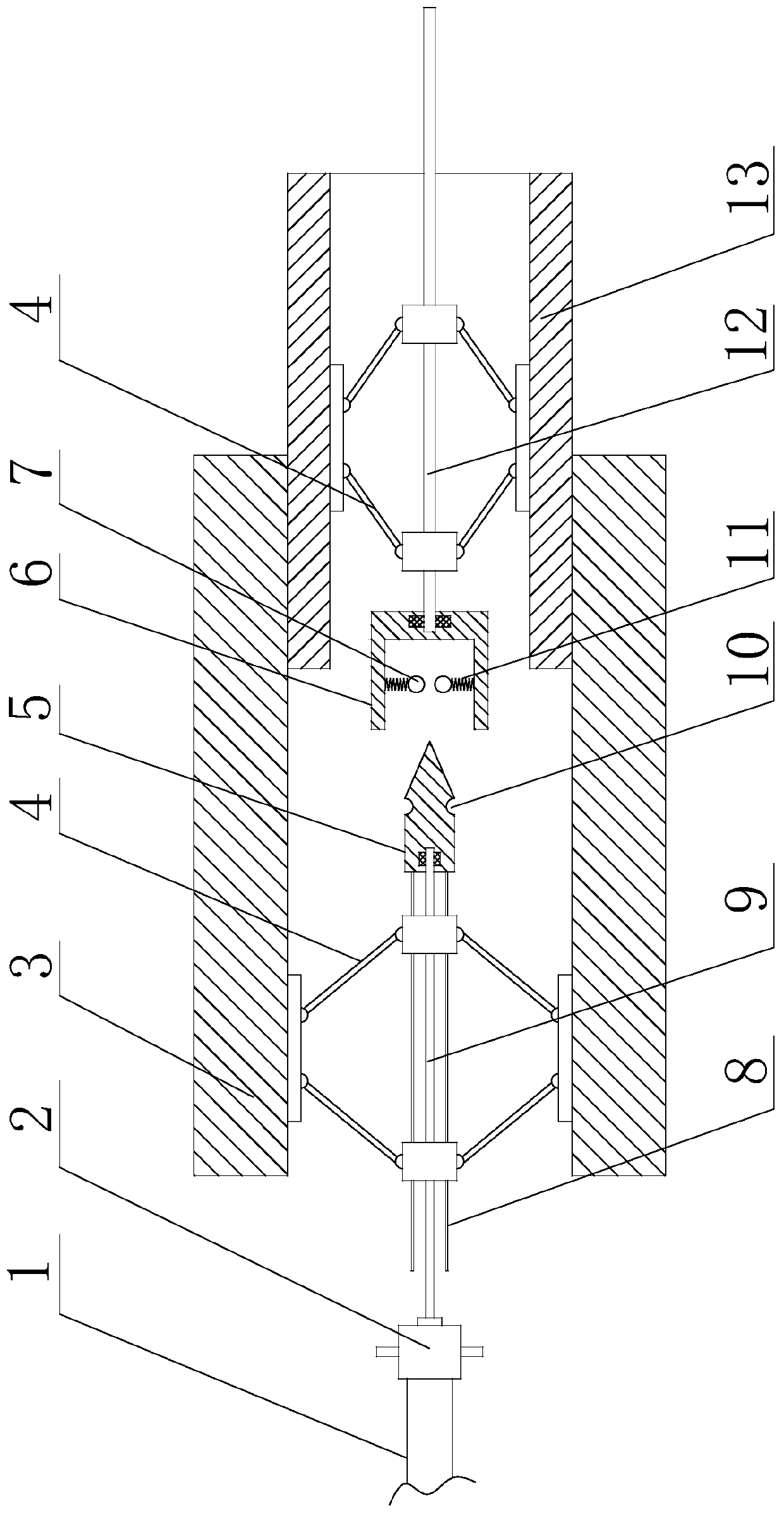

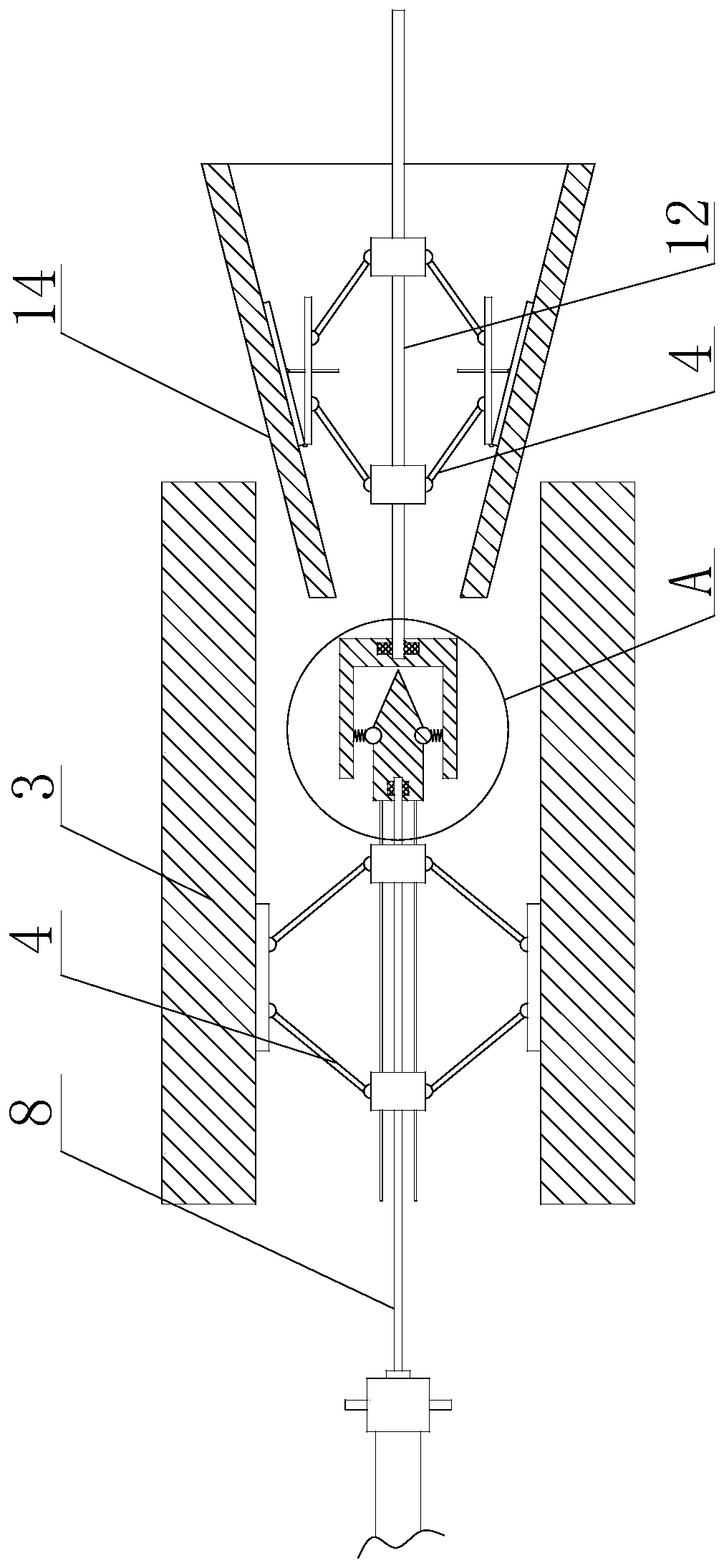

[0035] Such as Figure 1 to Figure 7 As shown, the present invention is an auxiliary device based on the application of the variable diameter die of the horizontal circular knitting machine, including the output shaft 1 of the hydraulic cylinder, including the first connecting rod 9 and the second connecting rod 12, and the first connecting rod 9 and the second connecting rod Both connecting rods 12 are provided with a clamping assembly 4, the clamping assembly 4 can clamp the inner diameter of the mould, and one end of the first connecting rod 9 is provided with a connecting assembly 2 for connecting with the hydraulic cylinder output shaft 1, And the output shaft 1 is detachably connected to the connecting assembly 2, the other end of the first connecting rod 9 is provided with a connecting column 5, the axis of the first connecting rod 9 coincides with the axis of the connecting column 5, and the first connecting rod 9 It can rotate around its own axis in the connecting col...

Embodiment 2

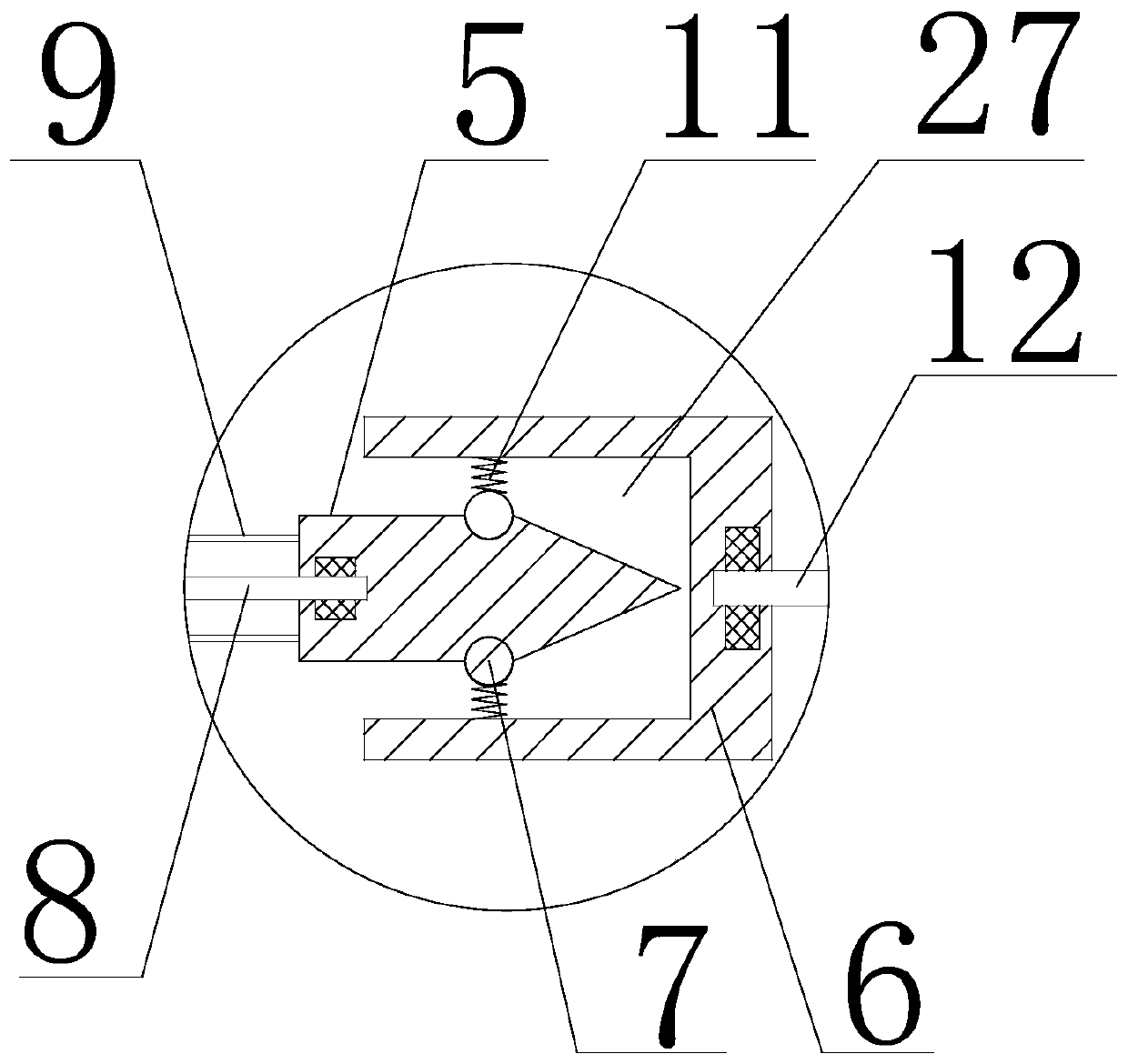

[0037] On the basis of Embodiment 1, the clamping assembly includes two movable blocks 19 and two clamping plates, and the first connecting rod 9 and the second connecting rod 12 are connected to the two movable blocks 19 by threads respectively. Both sides of the movable block 19 are provided with a movable rod 18, one end of the movable rod 18 is hinged with the movable block 19, and the other end is hinged with the clamping plate.

Embodiment 3

[0039] On the basis of Embodiment 2, the clamping plate includes a first clamping plate 15 and a second clamping plate 17, the second clamping plate 17 is hinged to the movable rod 18, and one end of the first clamping plate 15 is hinged to one end of the second clamping plate 17 , the first splint 15 can rotate around the hinge with the second splint 17 . The second splint 17 is also provided with an adjustment rod 16, the adjustment rod 16 is connected with the second splint 17 by threads, and when the adjustment rod 16 is rotated, the adjustment rod 16 can push the first splint 15 around the hinge with the second splint 17 turn.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com