Drilling technology for rock-socketed piles

A rock-socketed pile and hole-forming technology, which is applied to drilling equipment and methods, drill pipes, drill pipes, etc., can solve problems such as the inability to keep the slope of the steel casing consistent, the inclination of the hole formed is not straight, and the deviation of the drill bit , to achieve high straightness, low construction cost, and meet the construction requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

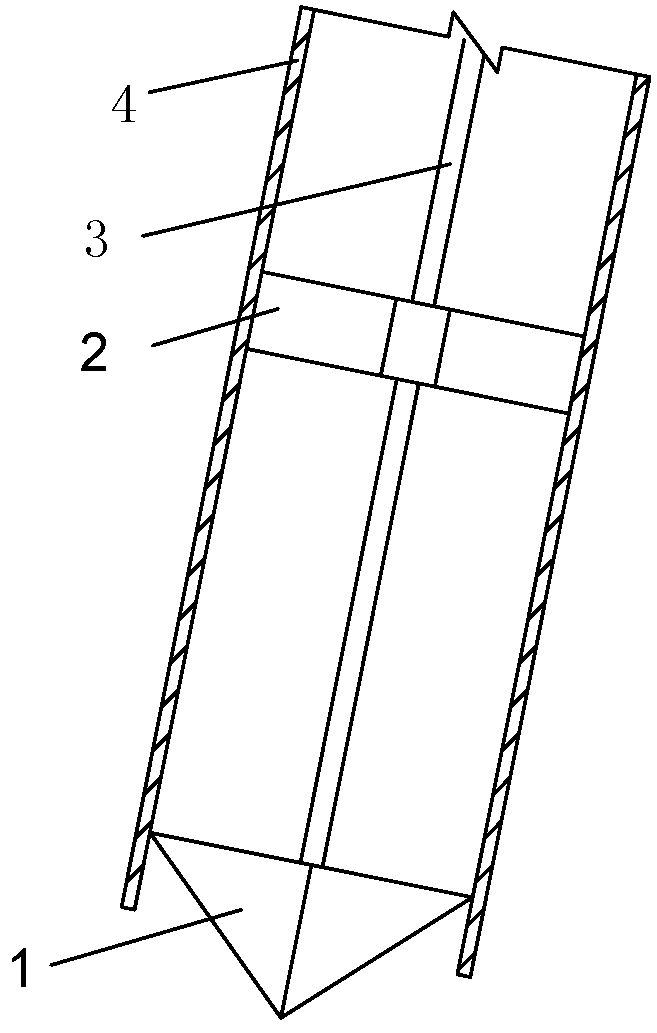

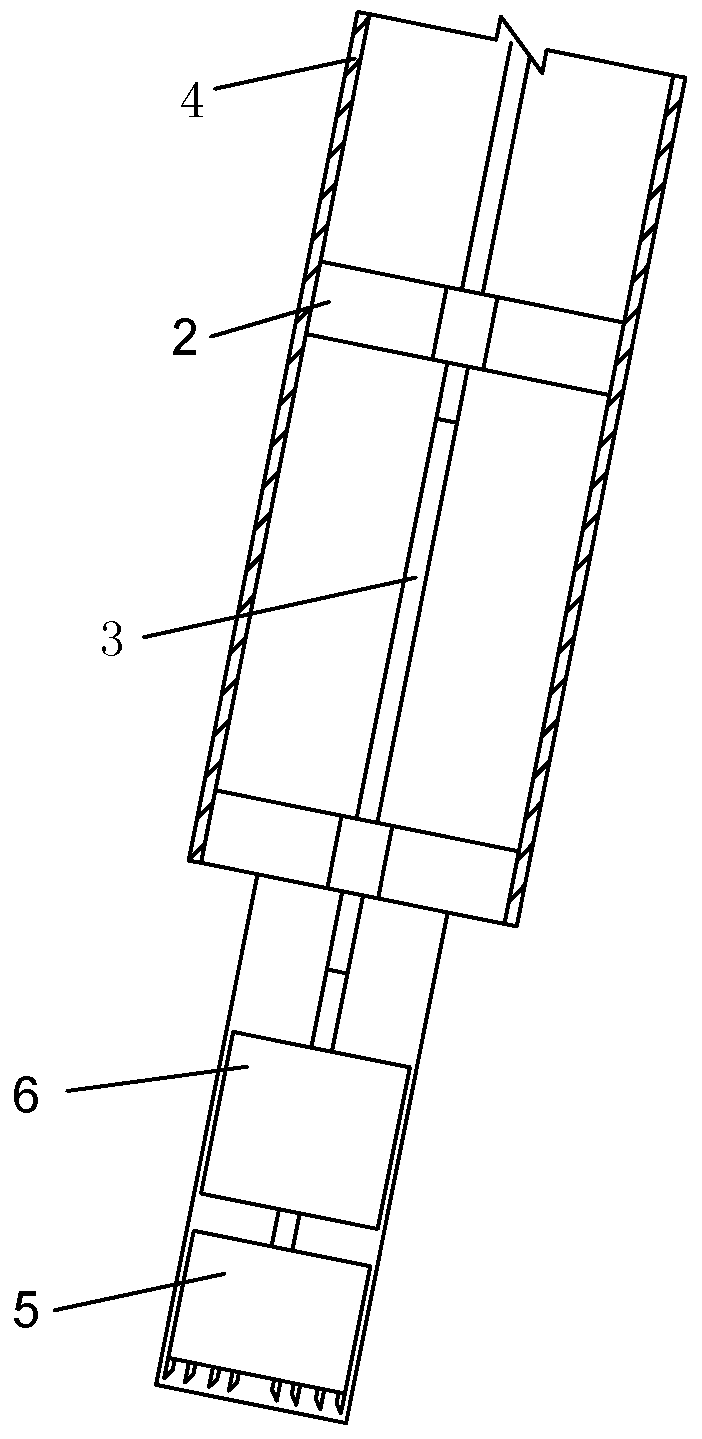

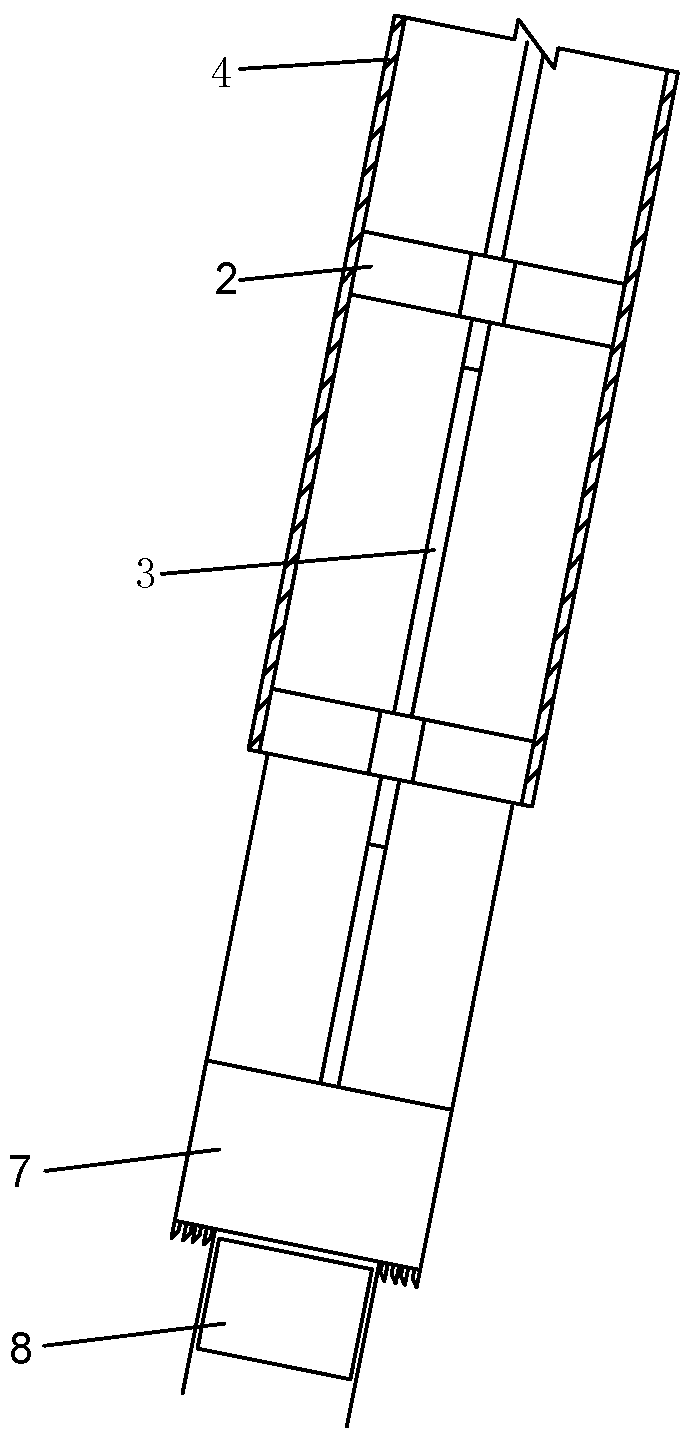

[0023] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, so that those skilled in the art can better understand the present invention and implement it, but the examples given are not intended to limit the present invention.

[0024] The invention is applied to the mooring pier construction project in the crude oil berth, relates to the construction technology of rock-socketed piles in the mooring pier construction project, and specifically relates to the drilling and hole-forming technology in the construction of full-section oblique rock-socketed piles.

[0025] The thickness of the overburden at the mooring pier is as follows: scattered strongly weathered tuff is selected as the bearing layer of the pile foundation at the front, and moderately weathered tuff is selected as the bearing layer of the pile foundation at the rear. The covering layers from top to bottom are: ① 1.9-2.8m thick gray silt conta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com