A head cutting machine for pe anti-corrosion pipe anti-corrosion layer

A technology of anti-corrosion layer and anti-corrosion pipe, which is applied in metal processing and other directions, can solve the problems of complex overall structure of equipment, high safety protection requirements, poor working environment, etc., and achieve the effect of safe and reliable construction, safe and reliable operation, and consistent slope

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

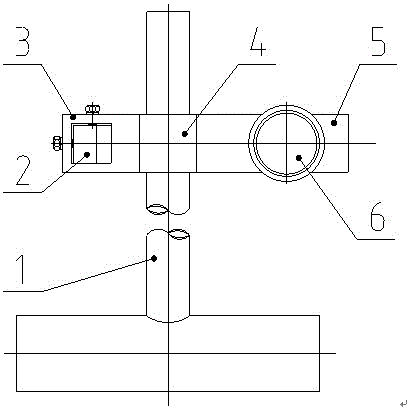

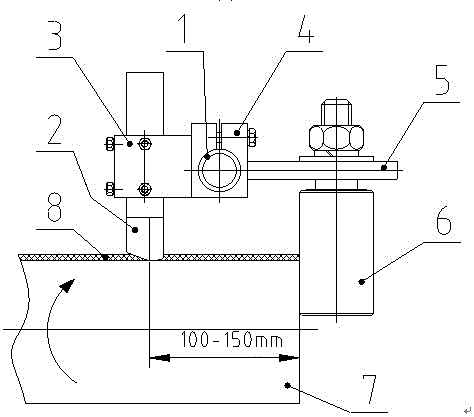

[0016] The detailed description and technical content of the present invention are described below with the accompanying drawings, but the accompanying drawings are only provided for reference and description, and are not intended to limit the present invention.

[0017] Refer to attached Figure 1-2 , a PE anti-corrosion pipe anti-corrosion layer cutting machine, including a column support rod 1 and a cutter 2 arranged on the column support rod, the column support rod is also provided with positioning rollers 6, and the cutter and positioning rollers are respectively positioned on the column Both sides of the support rod are facing the direction of the PE anti-corrosion layer 8 on the outside of the cut PE anti-corrosion steel pipe 7, and the centerlines of the cutter and the positioning roller are parallel to each other and are on the same horizontal plane. The tool is clamped in the tool clamping structure 3 , and the rear end of the positioning roller is adjustably connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com