A pipe gallery prefabricated part

A technology of prefabricated parts and pipe gallery, applied in construction, artificial island, infrastructure engineering, etc., can solve the problems of long construction period, poor use effect, complicated construction process, etc., to enhance the connection effect, increase the adsorption effect, Avoid leaking effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

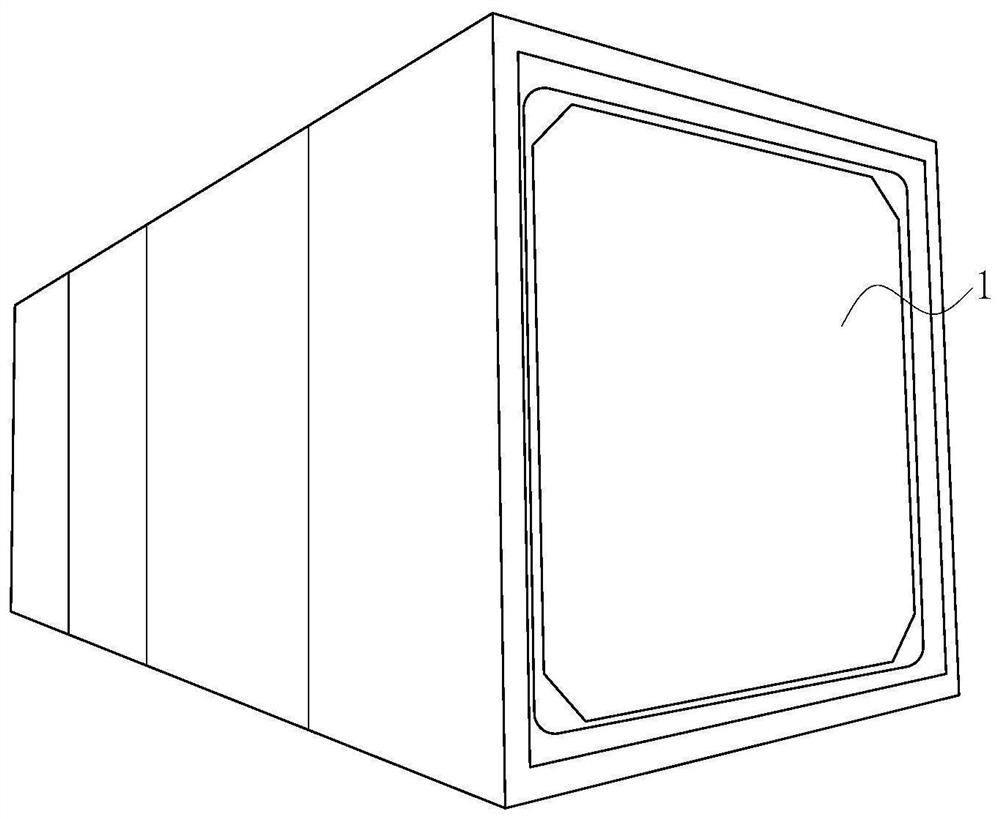

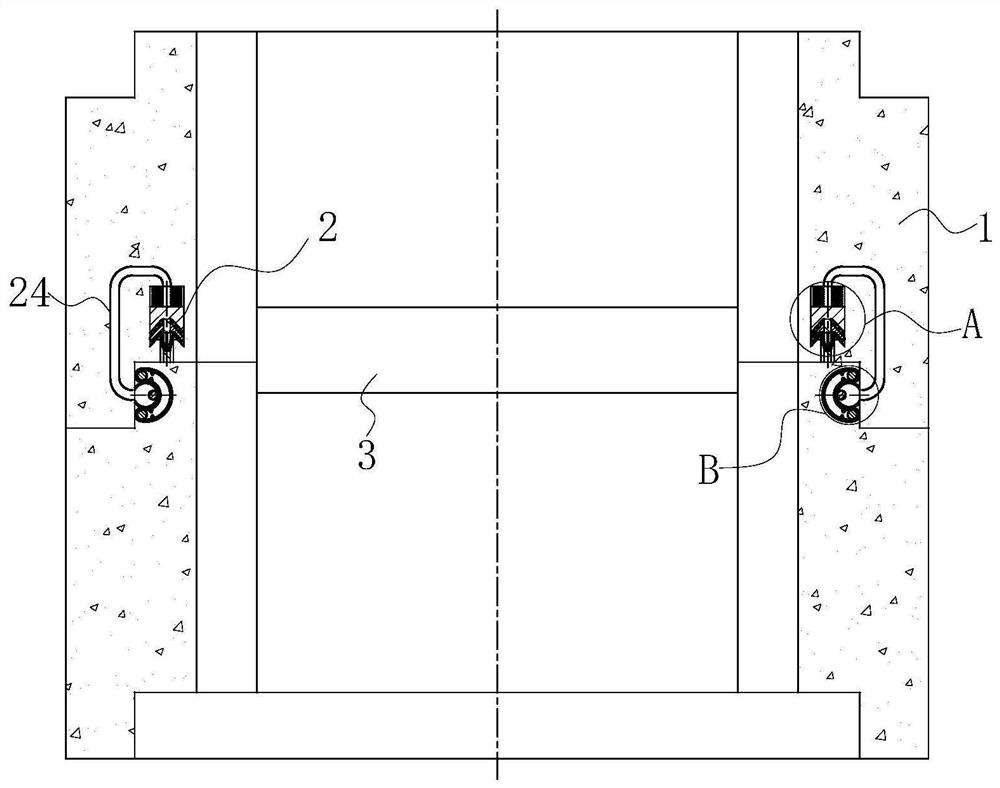

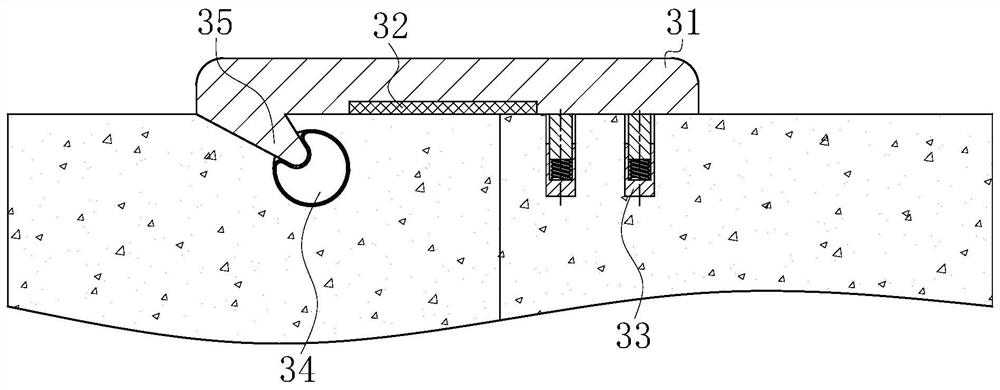

[0021] use Figure 1-Figure 6 A pipe gallery prefabricated part according to an embodiment of the present invention is described as follows.

[0022] Such as Figure 1-Figure 6 As shown, a pipe gallery prefabricated part according to the present invention includes a prefabricated part main body 1, a sealing mechanism 2 and a protection mechanism 3; the sealing mechanism 2 is arranged at the rear end of the prefabricated part main body 1, and the sealing mechanism 2 includes a mounting groove 21. Sliding block 22, extrusion rod 23, air delivery groove 24, No. 1 rubber airbag 25 and No. 2 rubber airbag 26; the installation groove 21 is evenly opened in the front end wall of the prefabricated part main body 1, and the installation groove 21 is at least opened There are eight, and the sliding block 22 is slidably connected to the installation slot 21 by a spring; the outer wall of the sliding block 22 can be in contact with the extrusion rod 23; the inner end of the extrusion rod 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com